Process for recycling waste concrete aggregate and cementing material

A technology of waste concrete and cementitious materials, applied in the field of concrete waste, to achieve the effects of uniform pressure distribution, good circularity, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

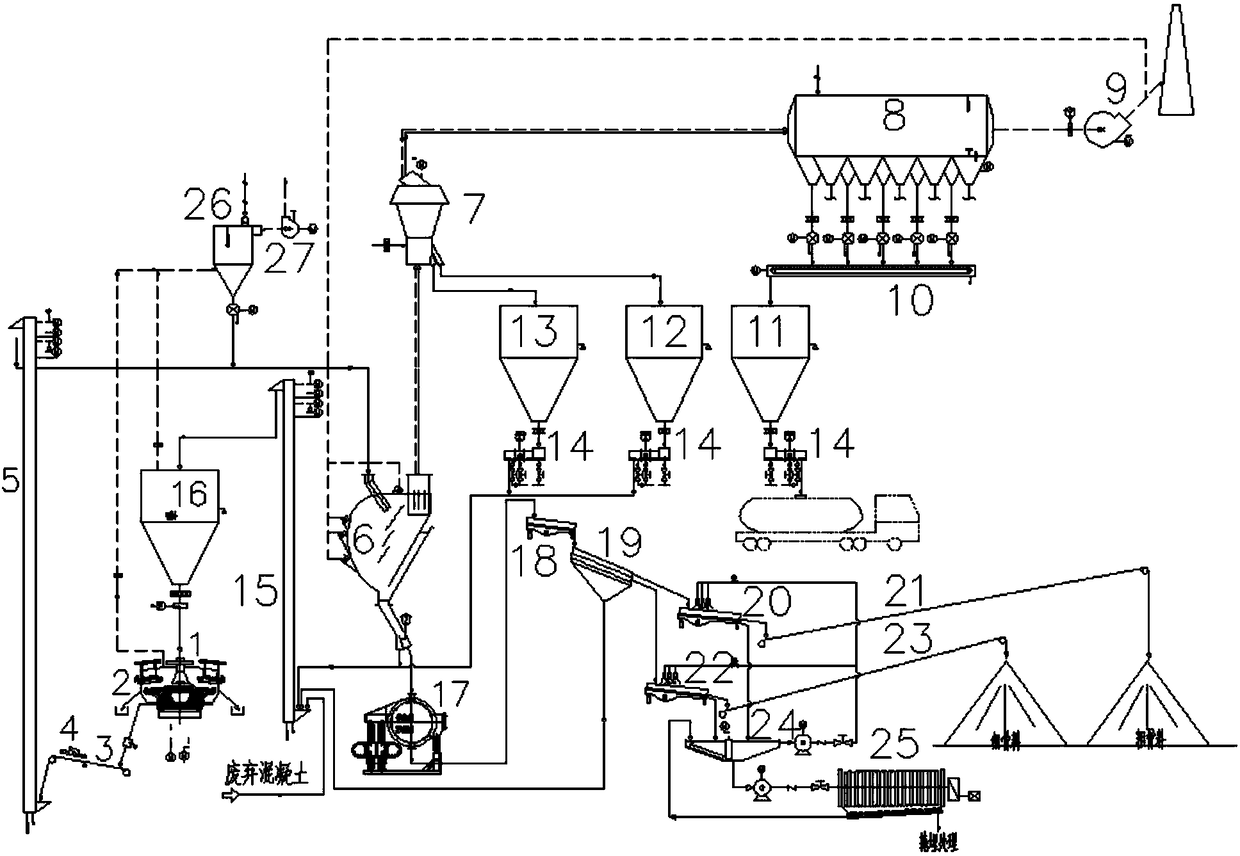

[0052] A process for recycling waste concrete aggregates and cementitious materials, including the following production processes:

[0053] 1. External circulation vertical mill separation: The external circulation vertical mill is used to process waste concrete to realize the separation of hard-to-grind aggregate and easy-to-grind porous cement hydrate;

[0054] 2. Combined separation and powder separation: static powder separator and dynamic powder separator are used for separation and powder separation; the static powder separator performs the separation of coarse material and powder after the external circulation vertical grinding; the dynamic powder separator performs coarse powder and Separation of fine powder;

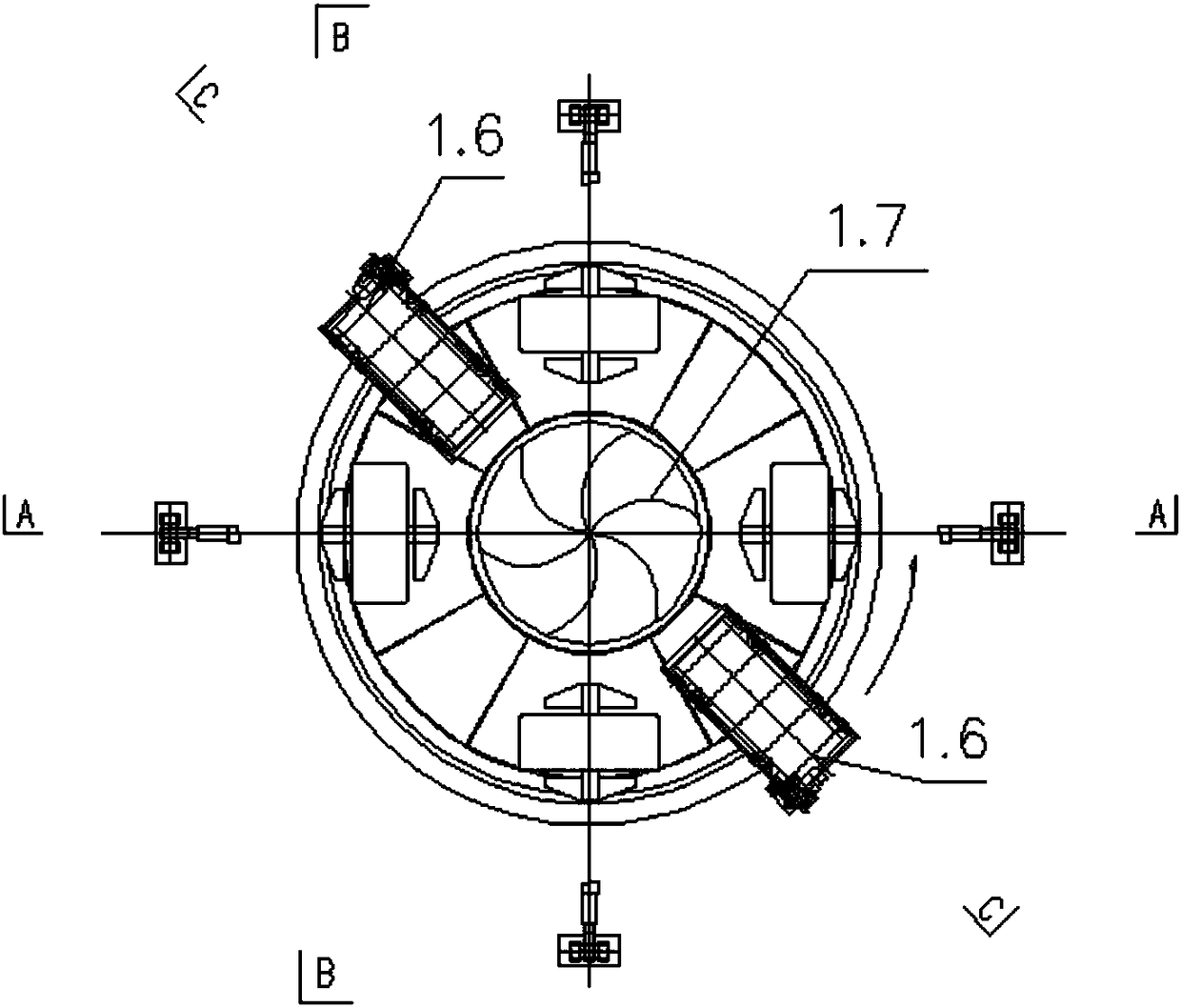

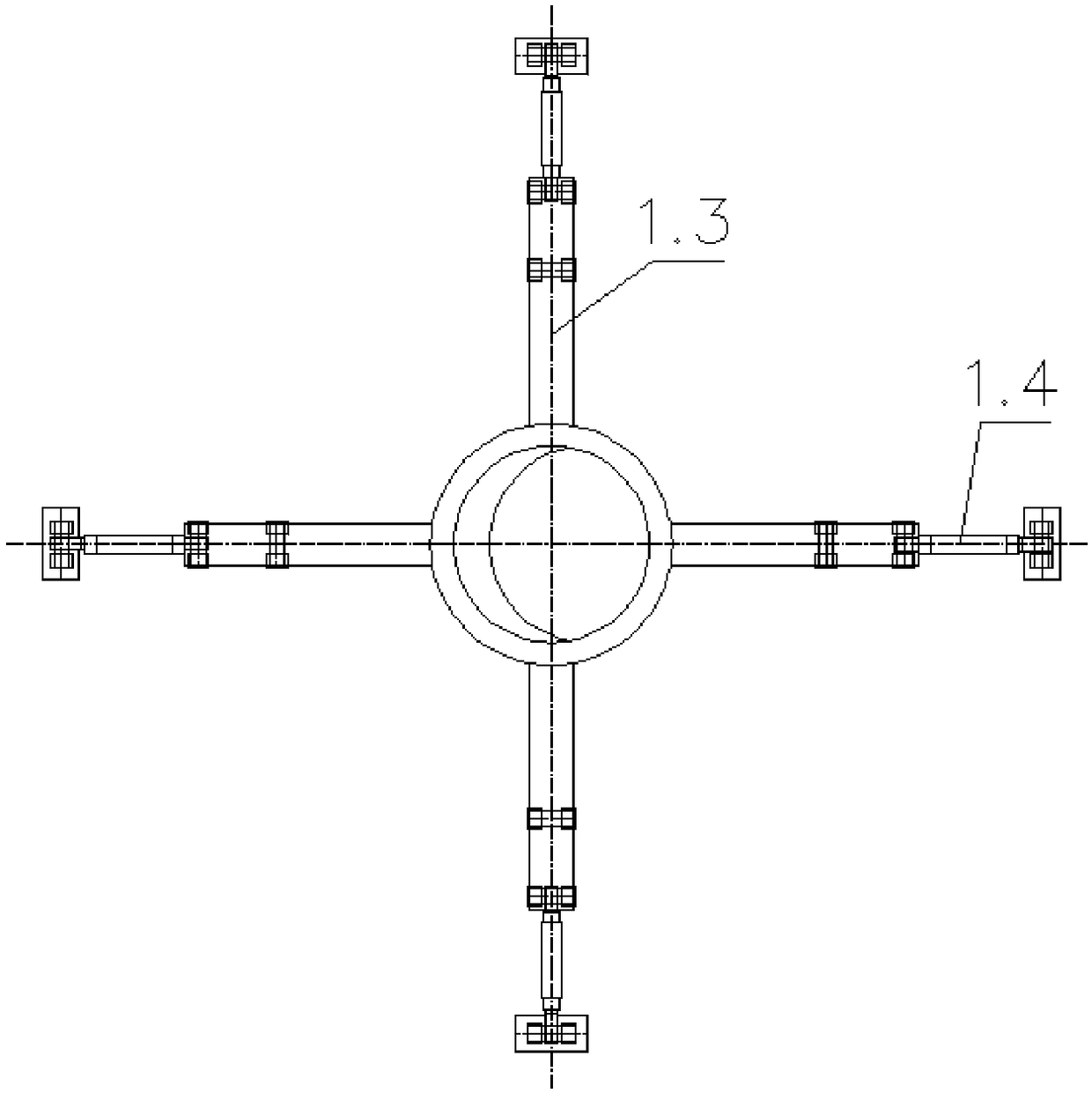

[0055] 3. Eccentric vibration mill: The eccentric vibration mill corrects the circularity of the aggregates sorted by the static separator and further removes the cemented material on the surface;

[0056] 4. Classification and water washing: The aggregate processed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com