Dynamic danger monitoring device and monitoring method for lime shaft kiln

A dynamic monitoring and shaft kiln technology, applied in the field of lime shaft kiln, can solve the problems of occupying operation space, cumbersome, high installation and maintenance costs, etc., and achieve the effect of small operation space occupation, improved safety factor, and simple monitoring method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

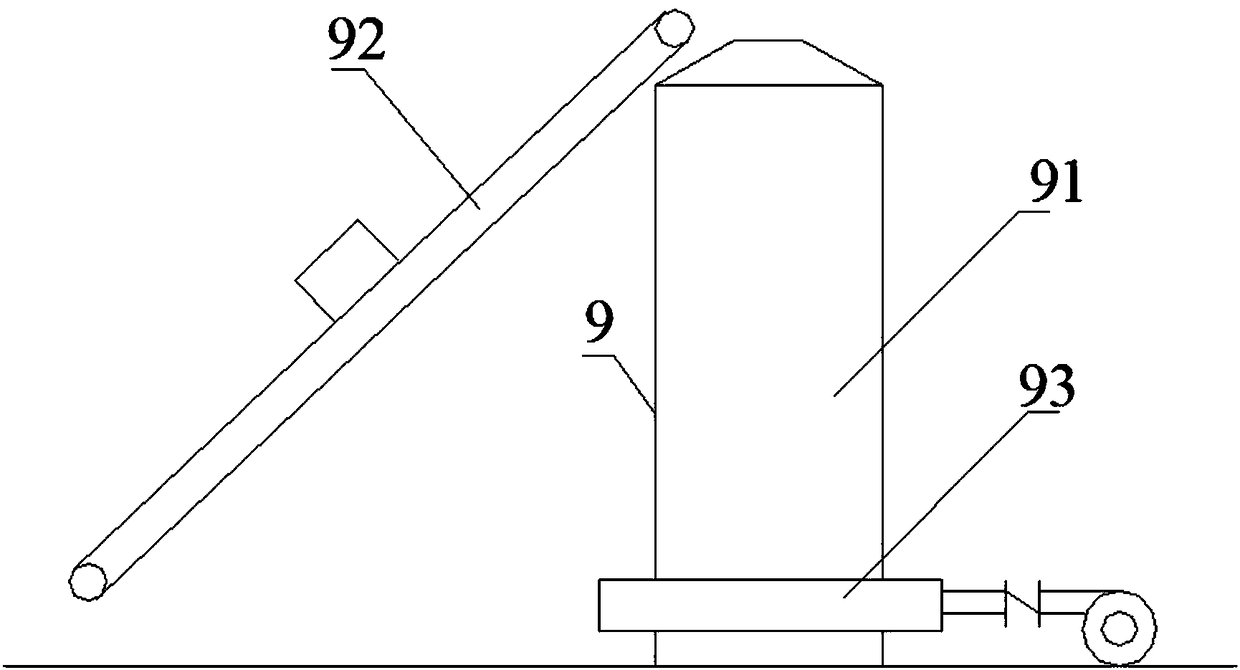

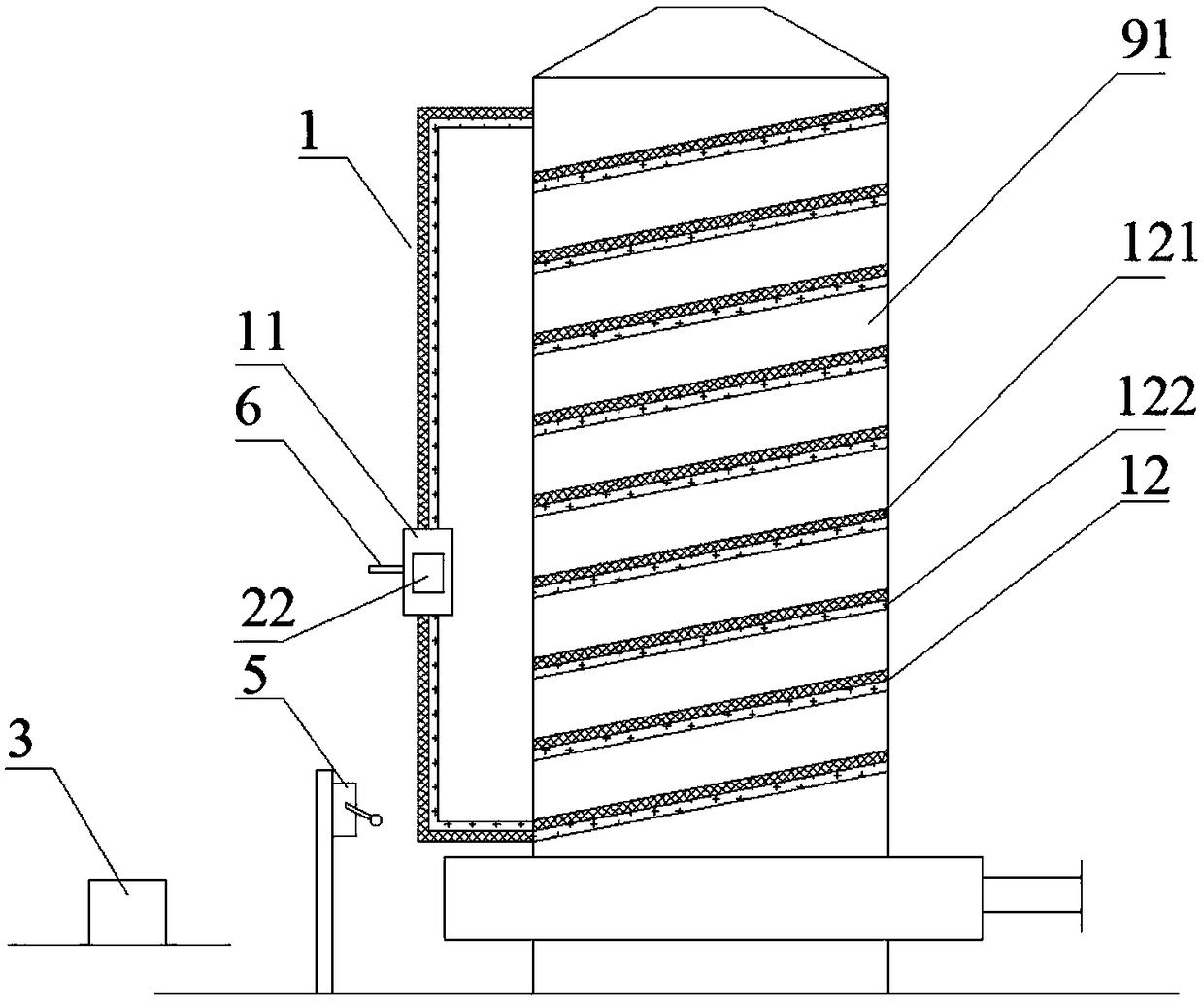

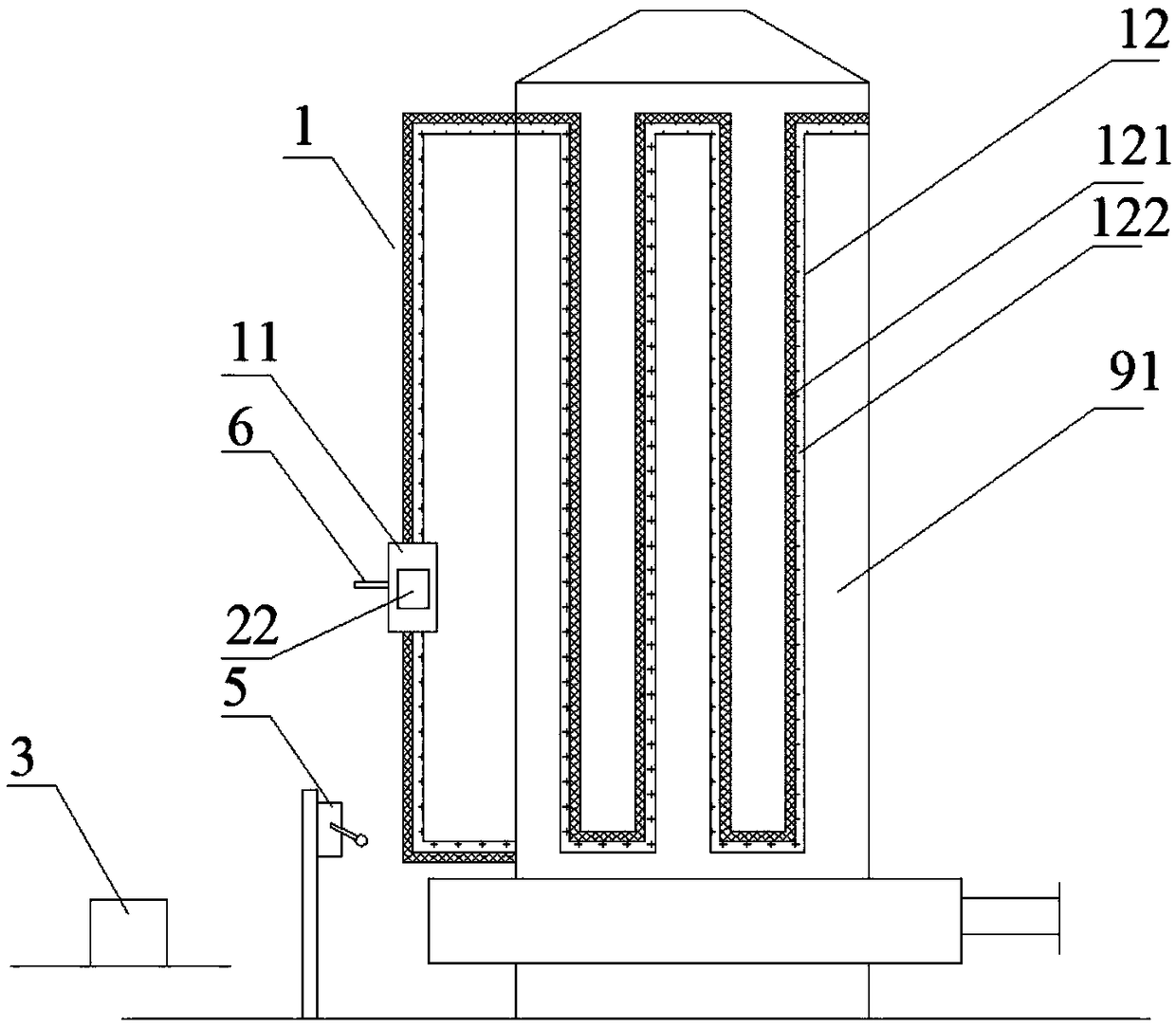

[0051] Such as figure 1 As shown, the lime shaft kiln 9 of the present embodiment is a dynamic monitoring device for lining peeling off. The lime shaft kiln 9 includes a shaft kiln body 91, a feeding device 92 and a blower device 93, and the feeding device 92 is arranged on the top of the shaft kiln body 91. , the blower device 93 is located at the bottom of the shaft kiln body 91, the dynamic monitoring device includes a patrol device 1, a temperature detector 22 and a controller 3, and the patrol device 1 includes a patrol robot 11, a driving device (including a driving motor and a walking wheel 26) With the track 12 arranged around the shaft kiln body 91, the temperature detector 22 is installed on the patrol robot 11, and the patrol robot 11 runs on the track 12 under the drive of the driving device, and the temperature detector 22 will receive around the shaft kiln body 91. The monitoring signal is transmitted to the controller 3 in real time.

[0052] In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com