A self-priming horizontal feed grinding mixer

A technology of a mixer and a feeder, which is applied to feed, mixers with rotary mixing devices, mixers, etc., can solve the problems of inability to automatically start mixing, low degree of automation, uneven thickness of feed, etc., to enhance practical performance and The degree of automation and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

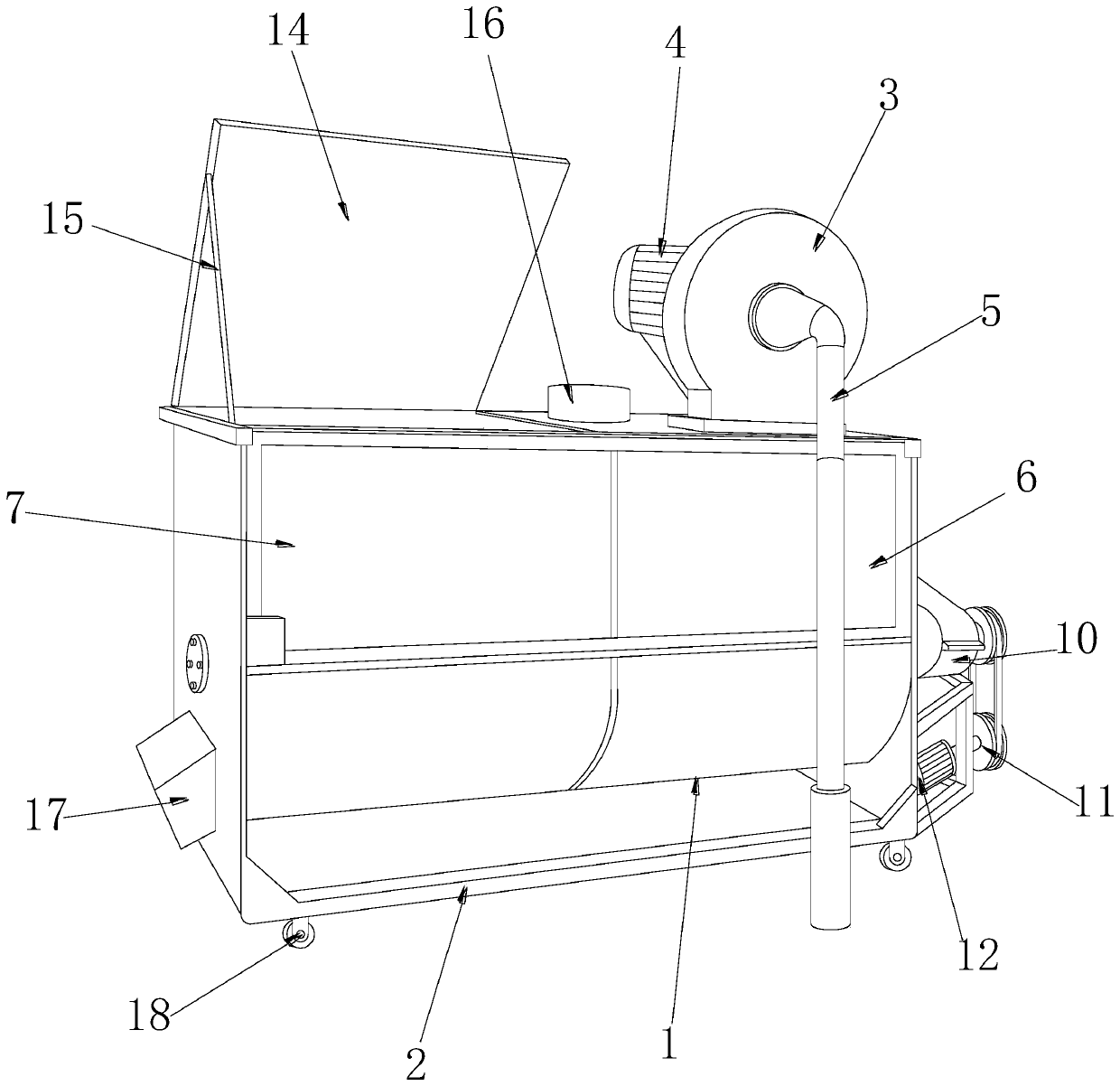

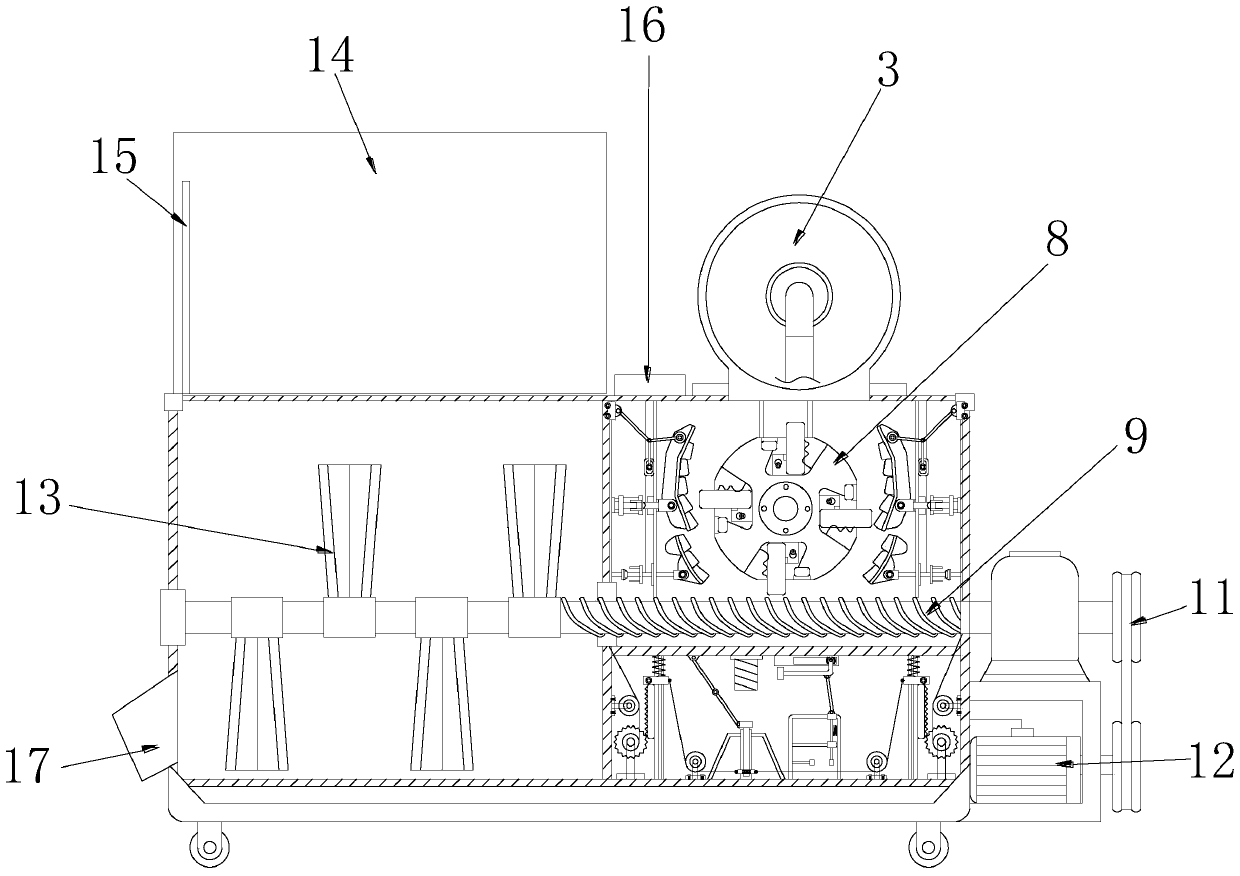

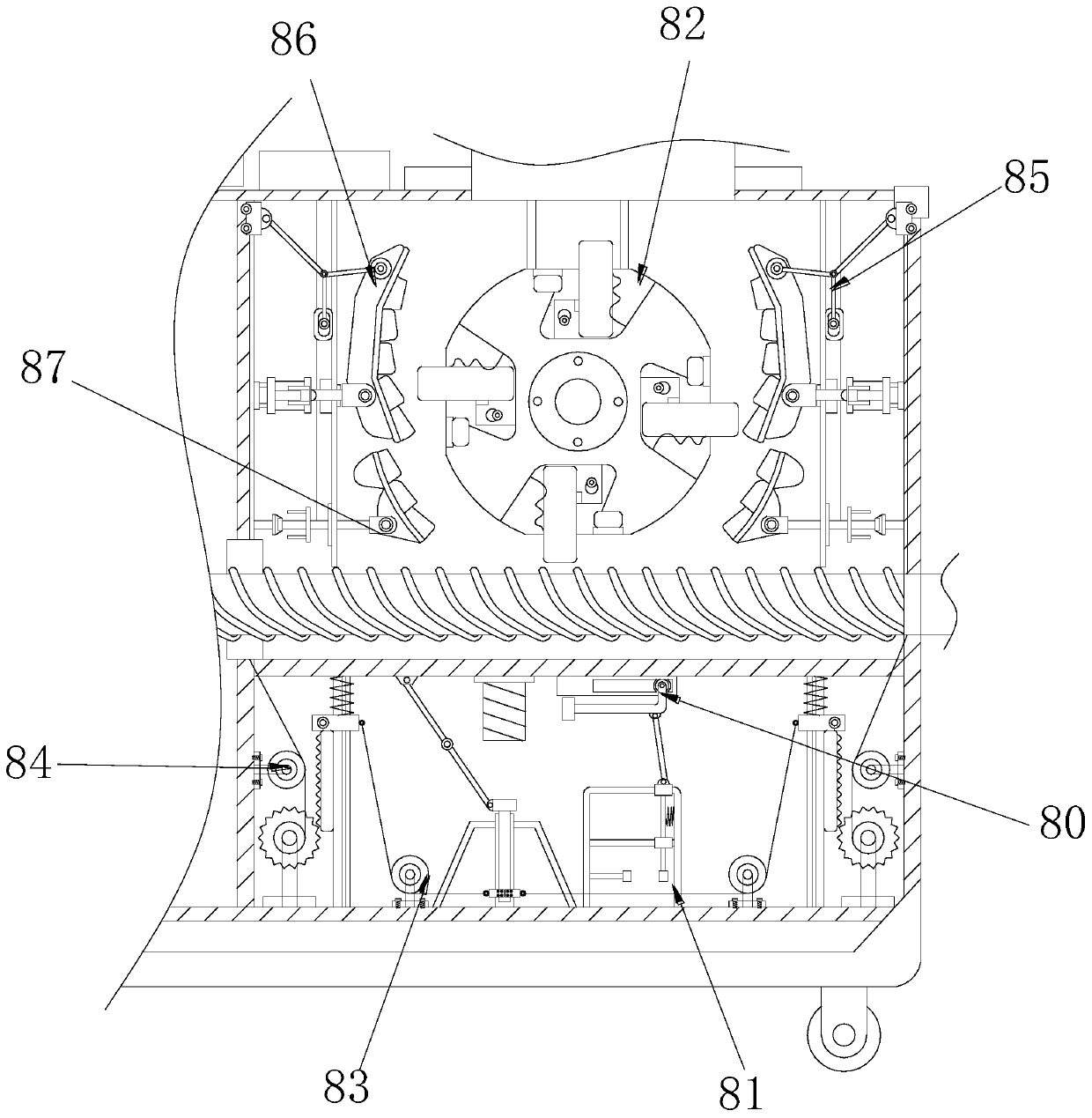

[0025] see Figure 1-Figure 5 , The present invention provides a technical scheme of a self-priming horizontal feed crushing mixer: its structure includes a crushing mixer body 1, a support frame 2, a wind suction machine 3, a suction crushing motor 4, a suction pipe 5, and a crushing chamber 6 , mixing chamber 7, high-efficiency automatic crushing device 8, pushing screw 9, reducer 10, pulley group 11, servo motor 12, stirring blade 13, mixing chamber door 14, door leaf bracket 15, air outlet 16, hopper 17, mobile Roller 18, the pulverizing and stirring body 1 is arranged inside the upper part of the support frame 2 and connected by electric welding, the wind suction machine 3 is arranged on the upper right of the pulverizing and ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com