Mesoporous magnetic nanometer iron oxide material, and preparation method and applications thereof

A technology of nano-iron oxide and magnetic nano-technology, which is applied in iron oxide, chemical instruments and methods, iron oxide/iron hydroxide, etc., can solve the problems of difficult reaction conditions, cumbersome process, and low utilization rate of raw materials, and achieve cheap and easy raw materials. The effect of large adsorption capacity and fast adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, a method for preparing magnetic nano iron oxide comprises the following steps:

[0037] a. Preparation of nano-iron oxide precursor:

[0038] Using CS(NH 2 ) 2 As a precipitant, weigh 0.048mol of CS(NH 2 ) 2 With 0.012mol of inorganic iron salt Fe 2 (SO 4 ) 3 Dissolve in 80ml of water to prepare a mixed aqueous solution of precipitating agent and inorganic iron salt, stir for 30min, transfer to a 100ml polytetrafluoroethylene-lined stainless steel reaction kettle, seal the reaction kettle and place it in a dry box at 200°C Carry out the hydrothermal reaction for 30 hours, then cool naturally to room temperature, filter out the product precipitate, and wash repeatedly with distilled water and absolute ethanol twice, until the cleaning solution of the product precipitate is neutral, and then the product precipitate Dry at a constant temperature of 60°C for 5h to obtain Fe 2 o 3 the precursor powder;

[0039] b. Mesoporous magnetic nano-Fe 2 ...

Embodiment 2

[0046] This embodiment is basically the same as Embodiment 1, especially in that:

[0047] In this embodiment, a method for preparing magnetic nano iron oxide comprises the following steps:

[0048] a. Preparation of nano-iron oxide precursor:

[0049] Using CS(NH 2 ) 2 As a precipitant, weigh 0.048mol of CS(NH 2 ) 2 With 0.012mol of inorganic iron salt Fe 2 (SO 4 ) 3 Dissolve in 80ml of water to prepare a mixed aqueous solution of precipitating agent and inorganic iron salt, stir for 30min, transfer to a 100ml polytetrafluoroethylene-lined stainless steel reaction kettle, seal the reaction kettle and place it in a dry box at 200°C Carry out the hydrothermal reaction for 30 hours, then cool naturally to room temperature, filter out the product precipitate, and wash repeatedly with distilled water and absolute ethanol twice, until the cleaning solution of the product precipitate is neutral, and then the product precipitate Dry at a constant temperature of 60°C for 5h to...

Embodiment 3

[0056] This embodiment is basically the same as the previous embodiment, and the special features are:

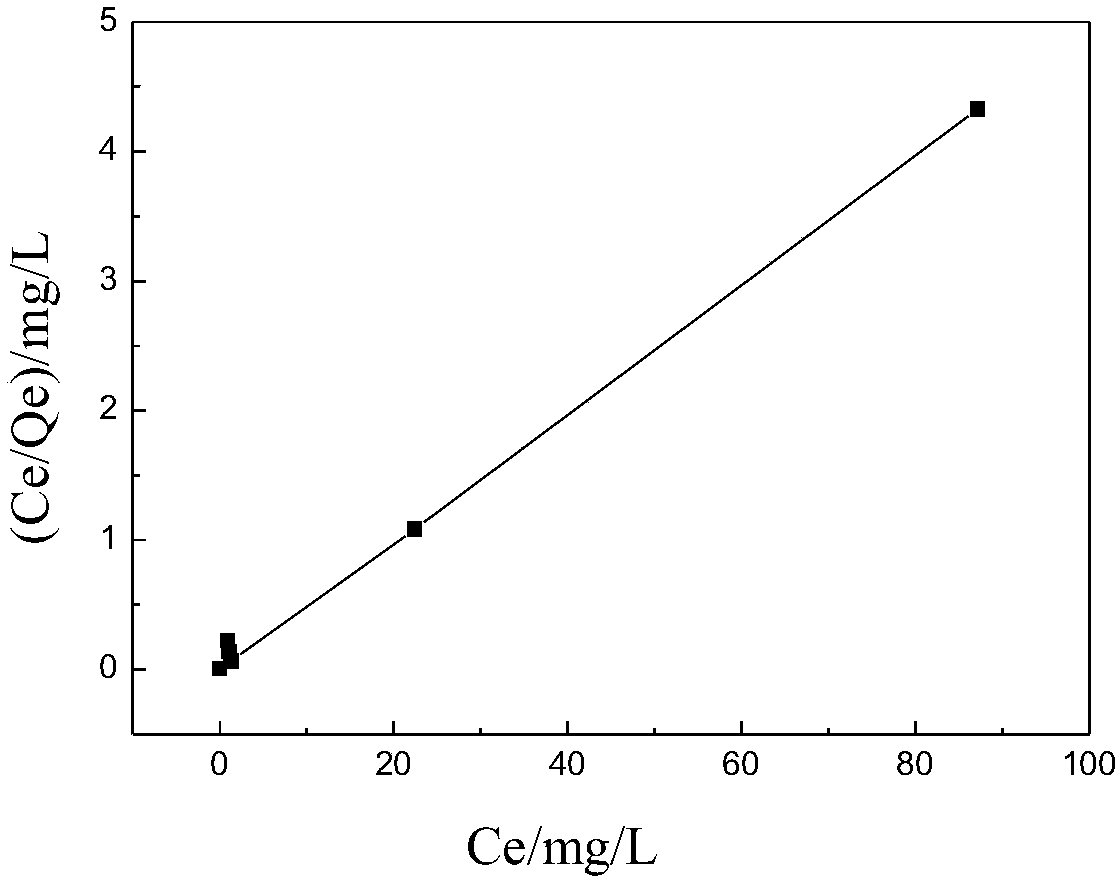

[0057] In this example, the mesoporous magnetic nano-Fe 2 o 3 material, the mesoporous magnetic nano-Fe 2 o 3 The material is used as an iron oxide Cr(VI) adsorbent, and the adsorption method is used to adsorb the highly toxic pollutant Cr(VI) in the heavy metal ion polluted water; and the adsorbent can separate the heavy metal Cr(VI) from the solution by controlling the external magnetic field. Separate and purify Cr-polluted wastewater.

[0058] In this example, when the magnetic nano-Fe 2 o 3 After the adsorption of Cr(VI) by the adsorbent reaches equilibrium, a magnetic rotor is used to mechanically stir the Cr(VI) solution to be adsorbed, so that the magnetic nano-Fe 2 o 3 The adsorbent is absorbed on the magnetic rotor, and then the magnetic rotor is taken out from the Cr(VI) solution to be adsorbed, so that the heavy metal Cr(VI) is separated from the solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com