Electrode graphite milling cutter and face milling cutter for machining oxide ceramics

A graphite and electrode technology, which is used in the field of end mills for processing oxide ceramics, can solve the problems of rapid wear and tear of milling tools and rapid wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

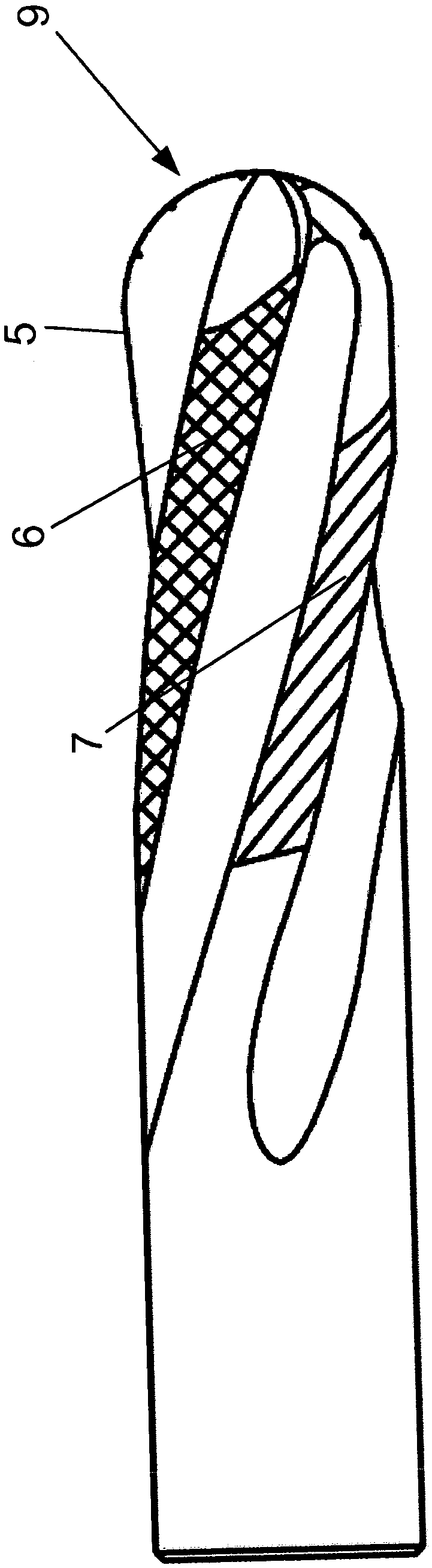

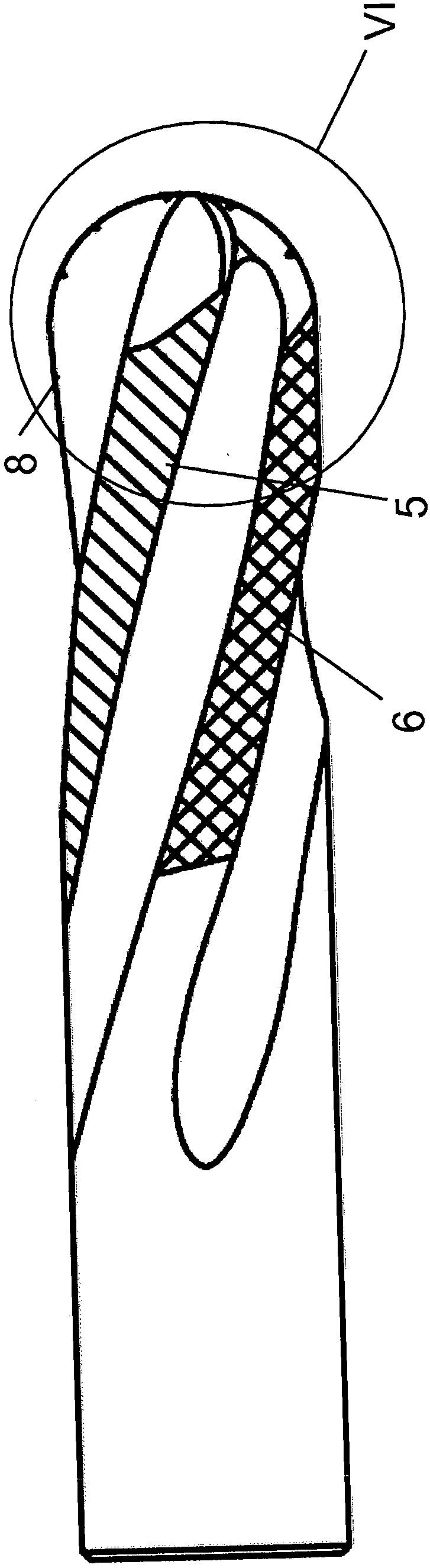

[0037] The electrode graphite milling cutter shown in the figure as especially from figure 1 It can be seen that there are four equidistantly spaced chip flutes 1 , 2, 3, 4 which surround the machining lands 5, 6, 7, 8 placed around the core segment of the electrode graphite milling cutter. spaced apart from each other. as by Figure 2-5 It can be seen that two of the processing blade lands 5, 6, 7, 8 are configured as rough machining blade faces 6, 8 with teeth 10, 11 forming peripheral side files, and the other two processing blades The lands are designed as finishing lands 5 , 7 with peripheral peripheral grooves which space the peripheral lands apart from each other, which each carry peripheral cutting edges 12 , 13 . Teeth 10, 11 and peripheral side cutting edges 12, 13 are here Image 6 and 7 are shown in and are respectively in the peripheral side working area enclosed by the imaginary cylindrical outer peripheral envelope.

[0038] The electrode graphite milling c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com