Remote high-precision vacuum sealing detection probe moving device and use method thereof

A technology of vacuum sealing and detection probe, which is used in measurement devices, liquid/vacuum degree measurement for liquid tightness, and fluid tightness test. , high application value, convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

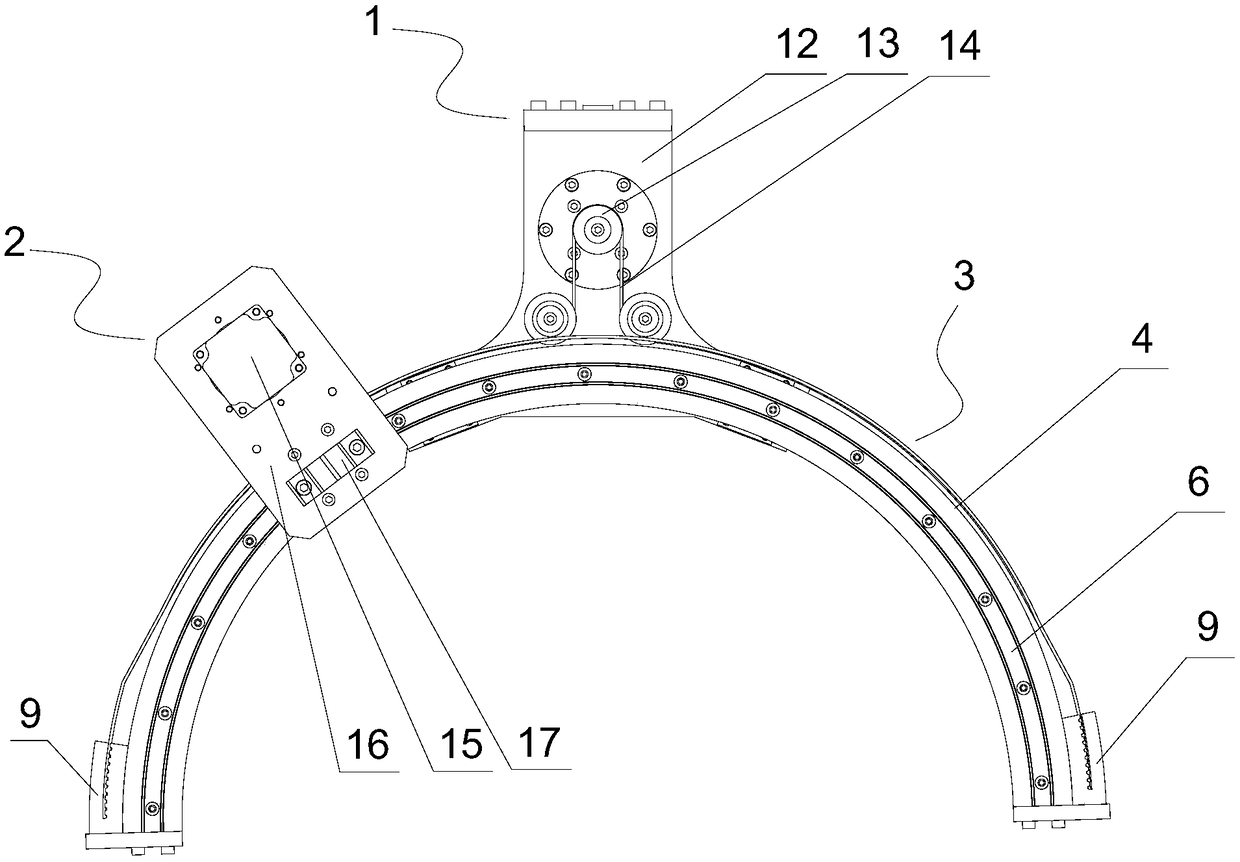

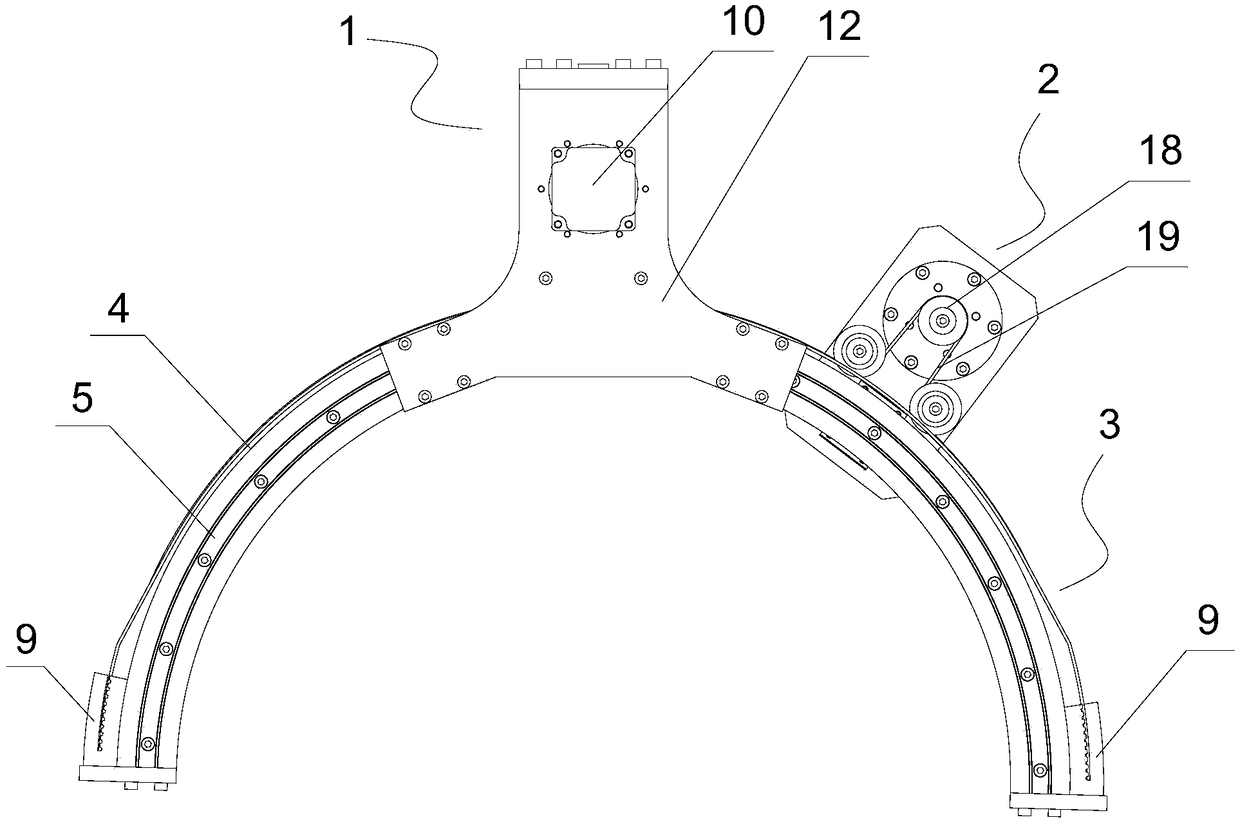

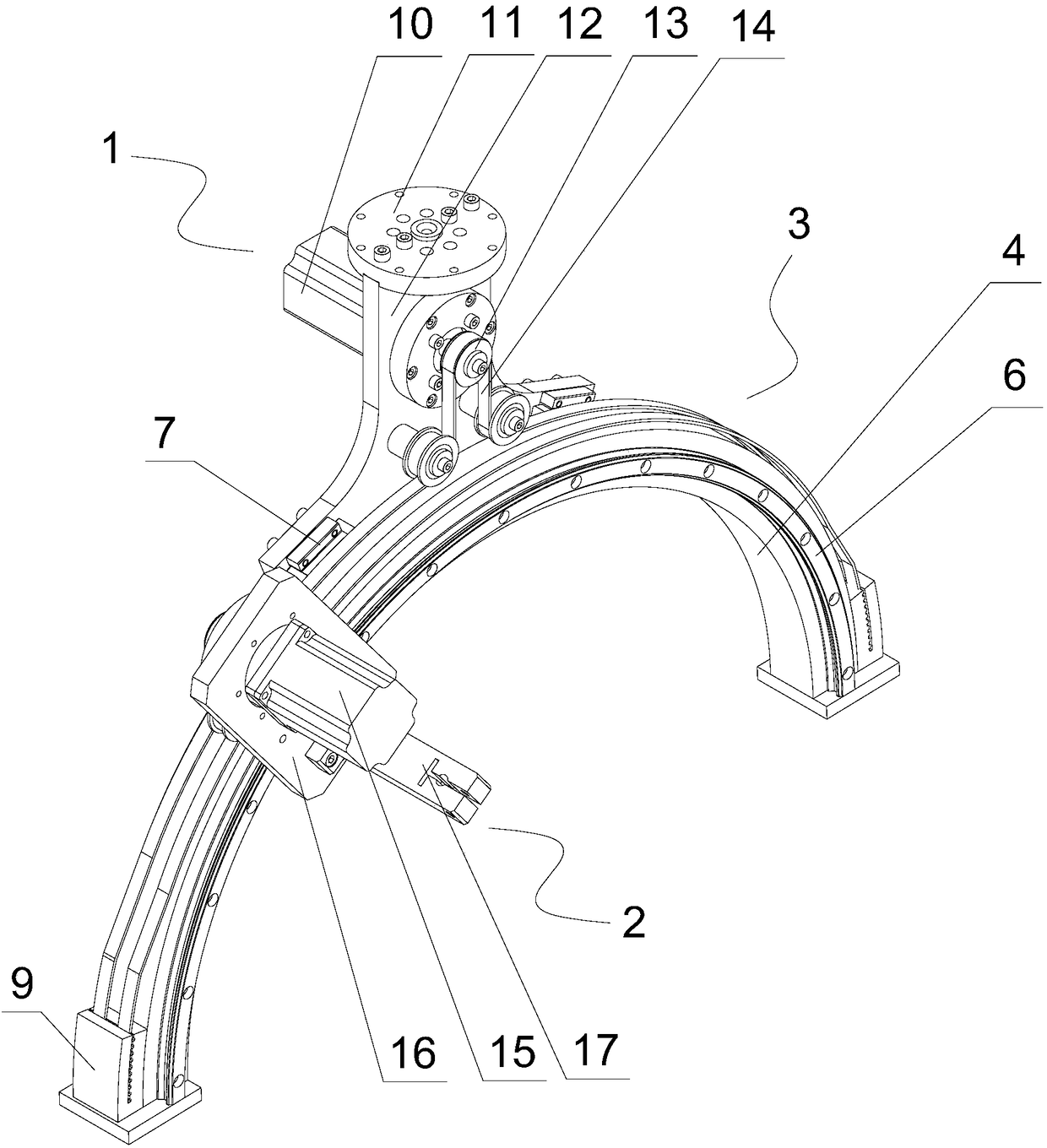

[0026] In this embodiment, a remote high-precision vacuum seal detection probe moving device, such as Figure 1-3 As shown, it includes the hoisting and fixing mechanism 1, the probe moving mechanism 2 and the arc guide rail mechanism 3. The guide rail mechanism performs the movement of the arc trajectory. In the structure of the device, the hoisting fixing mechanism and the probe moving mechanism are fixed as a whole, and are connected with the arc-shaped guide rail mechanism through the corresponding slider (namely the first slider or the second slider described below), and are fixed by hoisting. The relative movement between the mechanism and the arc guide mechanism, the relative movement between the probe moving mechanism and the arc guide mechanism. 360°) to detect the surface of the target pipe.

[0027] The arc guide rail mechanism comprises a guide rail fixing plate 4, a first guide rail 5 and a second guide rail 6, and the first guide rail and the second guide rail ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com