Method and device of coating chemical fiber braid with alumina layer

A kind of aluminum oxide layer and aluminum oxide technology, applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of reduced flexibility of chemical fiber webbing, peeling of aluminum oxide layer, and reduced strength of chemical fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

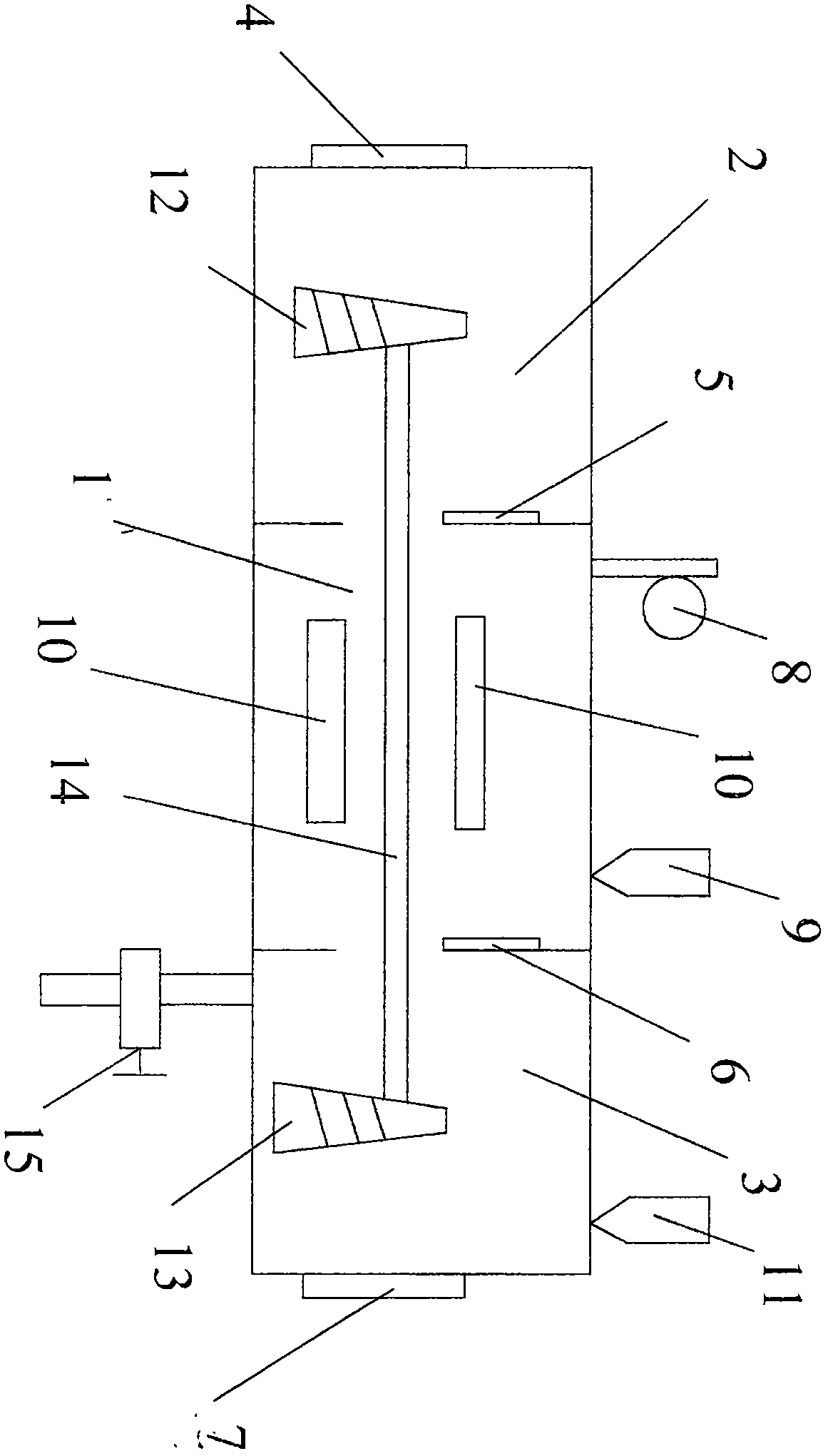

[0013] (1) Open the gate valves 5 and 6 between each chamber, open the discharge door 4, put the raw material tape winding shaft 12 wrapped with chemical fiber webbing into the raw material chamber 2 and fix it, pull out the chemical fiber webbing 14 and pass through the deposition chamber 1 to receive the coating. On the coating tape winding shaft 13 of the layer chamber 3, the rotation of the coating tape winding shaft 13 can make the chemical fiber webbing 14 enter the coating chamber 3 through the deposition chamber 1. Close the switch 15 of the discharge door 4, the alkyl aluminum tank 9, the oxygen-enriched air input pipe, the alumina storage tank 11, and the reclaiming door 7.

[0014] (2) Start the vacuum pump 8 to evacuate the three connected chambers to reach 10 -3 Turn off the vacuum pump 8 after Pa.

[0015] (3) Open the alkylaluminum tank 9 and pass the alkylaluminum gas into the deposition chamber 1 to keep the volume conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com