Non-asphalt color spraying rapid-hardening waterproof paint

A waterproof coating, non-asphalt technology, used in fire-resistant coatings, chloroprene homopolymer coatings, coatings, etc., can solve the problems of single color and no decorative function, and achieve simple spraying, strong decorative performance, and fast setting speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

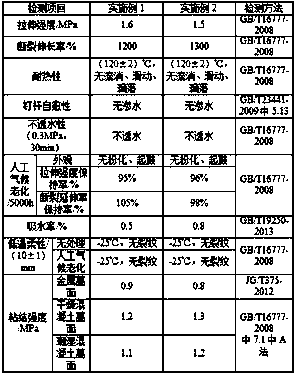

Embodiment 1

[0028] Embodiment 1 A kind of non-asphalt color spray quick-setting waterproof coating

[0029] The non-bituminous color spraying quick-setting component A and B are two components, and the proportion is 10:1 by weight;

[0030] The A component includes the following ingredients, in parts by weight:

[0031] 80 parts of hydrogenated tackifying resin, 30 parts of softening oil, 3 parts of sodium dodecylsulfonate, 0.5 parts of nonylphenol polyoxyethylene ether, 100 parts of water, 80 parts of rubber latex, 0.3 parts of silane coupling agent, antioxidant 0.5 parts of anti-UV agent, 0.4 parts of anti-UV agent, 0.3 parts of defoamer, and 3 parts of color paste.

[0032] The hydrogenated tackifying resin is a hydrogenated terpene resin; it comes from Yoshida Chemical, the model is 115-0#, the softening point is ≥115°C (ring and ball method), the color (iron-cobalt method) is ≤0-1 (special grade), and the acid value is >1.0 mgKOH / g, saponification value≤1.5 mgKOH / g, iodine value≤40...

Embodiment 2

[0045] Example 2 A non-asphalt color spray quick-setting waterproof coating

[0046] The non-bituminous color spraying quick-setting components A and B of the present invention have a ratio of 8:1 by weight

[0047] The A component includes the following ingredients, in parts by weight:

[0048] 70 parts of hydrogenated tackifying resin, 30 parts of softening oil, 3 parts of sodium dodecylsulfonate, 1 part of nonylphenol polyoxyethylene ether, 100 parts of water, 70 parts of rubber latex, 0.3 parts of silane coupling agent, antioxidant 0.5 part of anti-UV agent, 0.4 part of anti-UV agent, 0.3 part of defoamer, and 1 part of color paste.

[0049] The hydrogenated tackifying resin is a hydrogenated C5 resin;

[0050] Described softening oil is dioctyl adipate;

[0051] The rubber latex is neoprene latex; the model is Synthomer Lipren B, the solid content is 57.5-58.5%, the pH value is 12.5-13.5; the viscosity (Brookfield viscometer) is 40-120mPa.s, and the glass transition te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Saponification value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com