Performance test table for compressor and using method

A technology of compressors and test benches, which is applied in the field of compressors, can solve the problems of increasing the cost of experiments and single applicability of test equipment, achieve high applicability, reduce the possibility of high temperature aging cracking, and reduce the effect of test errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

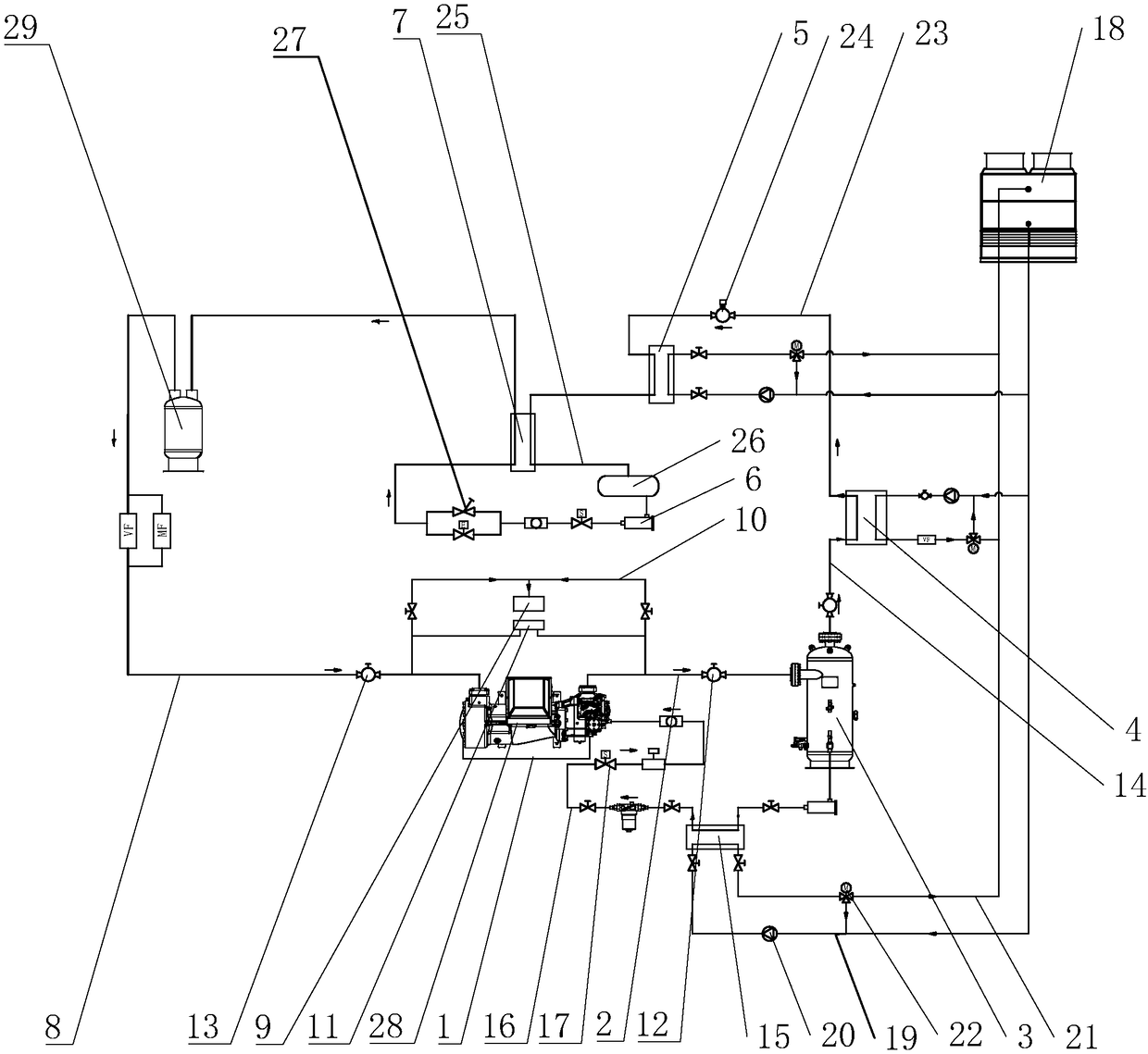

[0048] Such as figure 2 As shown, a performance test bench for a compressor includes a frame 1 on which an exhaust pipe 2, an oil separator 3, a calorimeter 4, a condenser 5, a dry filter 6, Evaporative condenser 7, gas-liquid separator 29 and suction pipe 8. A vacuum pump 9 is installed on the frame 1, and an exhaust pipe 10 is connected between the exhaust pipe 2 and the suction pipe 8 and the vacuum pump 9. Both the exhaust pipe 2 and the suction pipe 8 are provided with a pressure controller 11, the exhaust pipe 2 is provided with an exhaust valve 12 for controlling the opening and closing of the exhaust pipe 2, and the suction pipe 8 is provided with a pressure controller 12 for controlling the suction pressure. Pipe 8 opens and closes suction valve 13.

[0049] The exhaust pipe 2 is connected to the exhaust port of the compressor 28 , and one end of the exhaust pipe 2 is connected to the liquid inlet end of the oil separator 3 , and the first connecting pipe 14 is con...

Embodiment 2

[0060] The difference between embodiment two and embodiment one is:

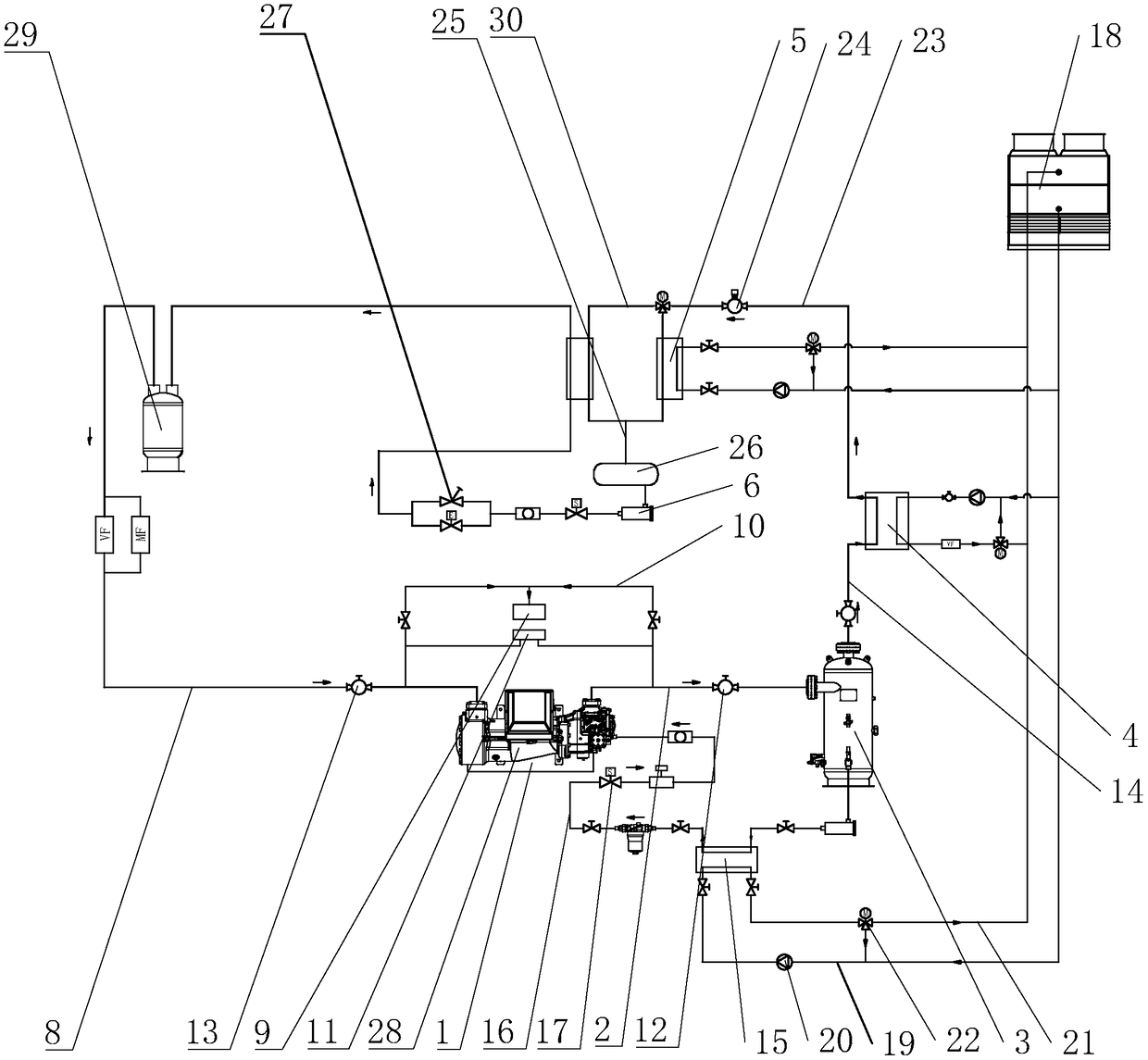

[0061] Such as image 3 As shown, the second connecting pipe 23 is directly connected to the liquid inlet end of the dry filter 6 . One side of the second connecting pipe 23 is connected with a third connecting pipe 30 , the third connecting pipe 30 is connected to the liquid inlet end of the evaporative condenser 5 , and the liquid outlet end of the evaporative condenser 5 is connected to the liquid inlet end of the fourth connecting pipe 25 .

[0062] Part of the high-temperature and high-pressure refrigerant gas discharged from the compressor 28 enters the condenser 5 for condensation, and the other part enters the evaporative condenser 5 for condensation, and becomes a supercooled liquid after being condensed, and enters the evaporative condenser 5 after being throttled by the electronic expansion valve 27. After absorbing heat in the evaporative condenser 5, the overheated gas is sucked by the compress...

Embodiment 3

[0064] S1. Connect the discharge pipe 2 to the discharge port of the compressor 28, connect the suction pipe 8 to the suction port of the compressor 28, and connect the oil supply pipe 16 to the oil supply port of the compressor 28;

[0065] S2. Connect the high-pressure connection pipeline of the compressor 28 under test to the high-pressure pressure measurement point and the discharge temperature measurement point, and the 28 low-pressure connection pipelines of the compressor under test to connect the low-pressure pressure measurement point and the discharge temperature measurement point. The air in the machine 28 is exhausted;

[0066] S3, open the exhaust valve 12, the suction valve 13, and the oil supply valve 17 in sequence;

[0067] S4, making the regulating valve 24 reach a prescribed opening degree;

[0068] S5, turn on the water pump 20 and the compressor under test 28, and gradually open the loading solenoid valve on the compressor under test 28;

[0069] S5. Obs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com