Cold cathode spot lamp

A technology for cold cathode and cold cathode fluorescent lamps, which is applied to the parts, lighting devices, light sources and other directions of gas discharge lamps, can solve the problems of unfavorable environmental protection, unsuitable indoor and outdoor decoration, difficult and accurate control of mercury content in lamps, etc. To achieve the effect of preventing human injury, reducing eye fatigue, and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

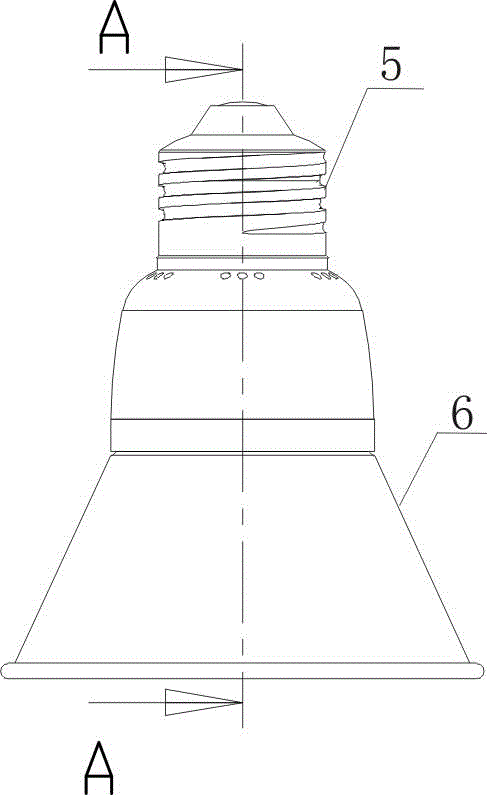

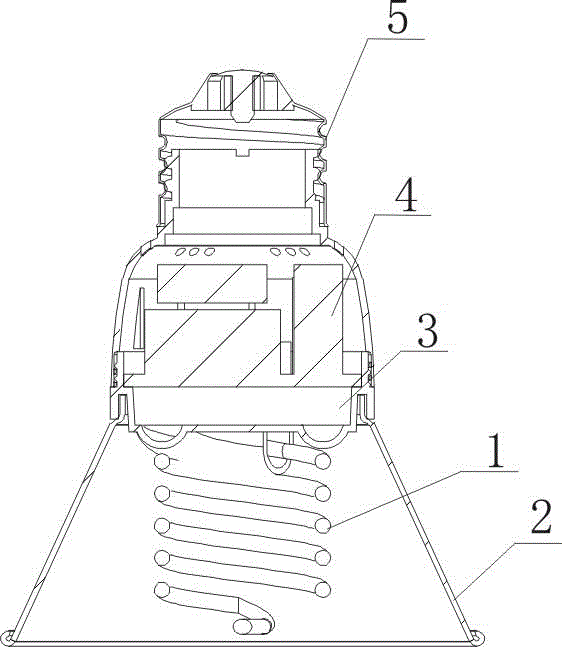

[0028] Such as figure 1 , figure 2 with image 3 As shown, the present invention includes a lamp holder 5 , an inverter 4 is installed inside the lamp holder 5 , the lower end of the lamp holder 5 is engaged with a CCFL assembly 6 , and the CCFL assembly 6 is connected to the inverter 4 .

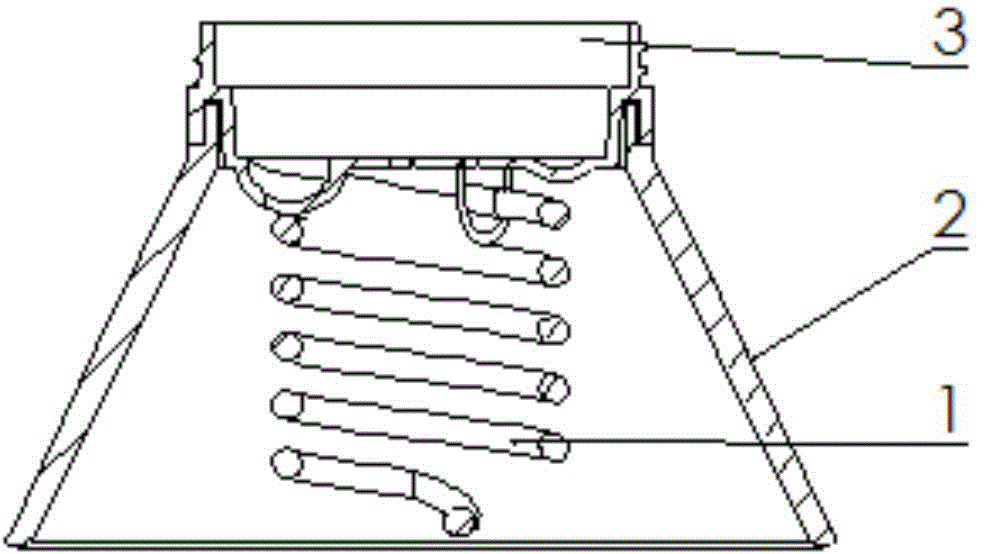

[0029] In the cold cathode fluorescent lamp assembly 6, the upper end of the plastic part 3 is fastened with the lamp holder 5, the cold cathode fluorescent lamp tube 1 and the spotlight cup 2 outside the cold cathode fluorescent lamp tube 1 are installed at the lower end of the plastic part 3, and the cold cathode fluorescent lamp tube 1 The electrodes are connected to the output terminals of the inverter 4 .

[0030] The lower end of the plastic part 3 is provided with a threaded groove, which is used to limit the position of the lamp tube 1 and the spotlight cup 2. The contact parts are glued with soft silicone in an appropriate way to form a whole; the silicone will wrap the lamp tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com