Upper beam moving device of motor shaft-pressing hydraulic press

A mobile device and hydraulic press technology, applied in the field of hydraulic press devices, can solve problems such as increasing efficiency and reducing cost, and achieve the effects of increasing efficiency, reducing cost and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

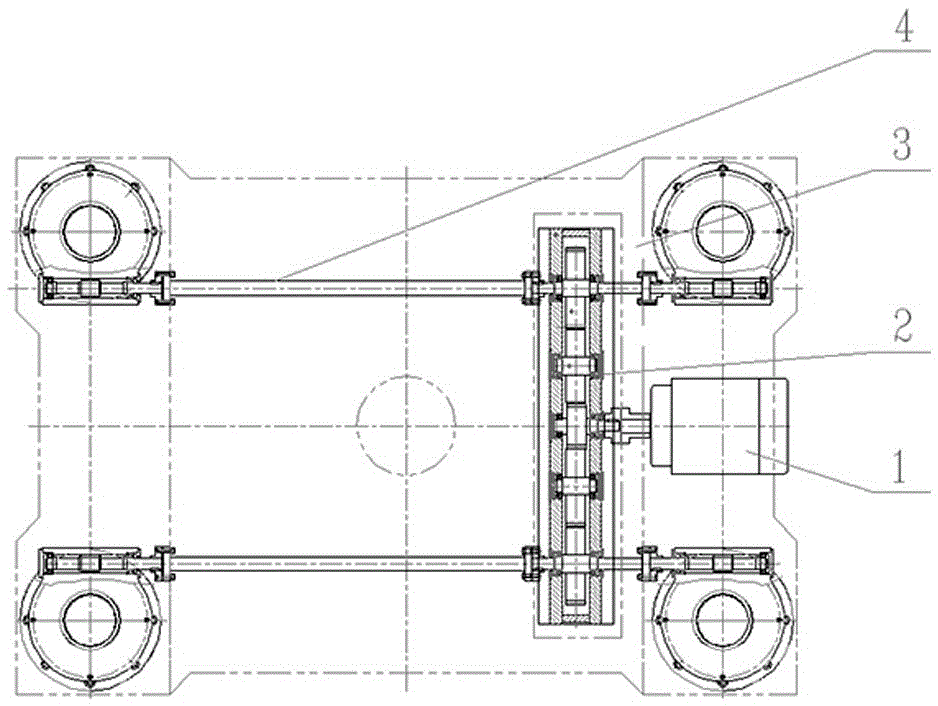

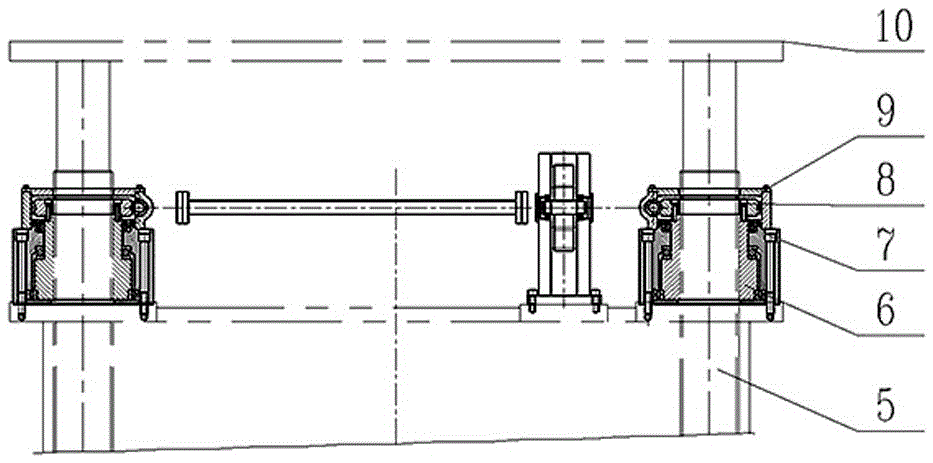

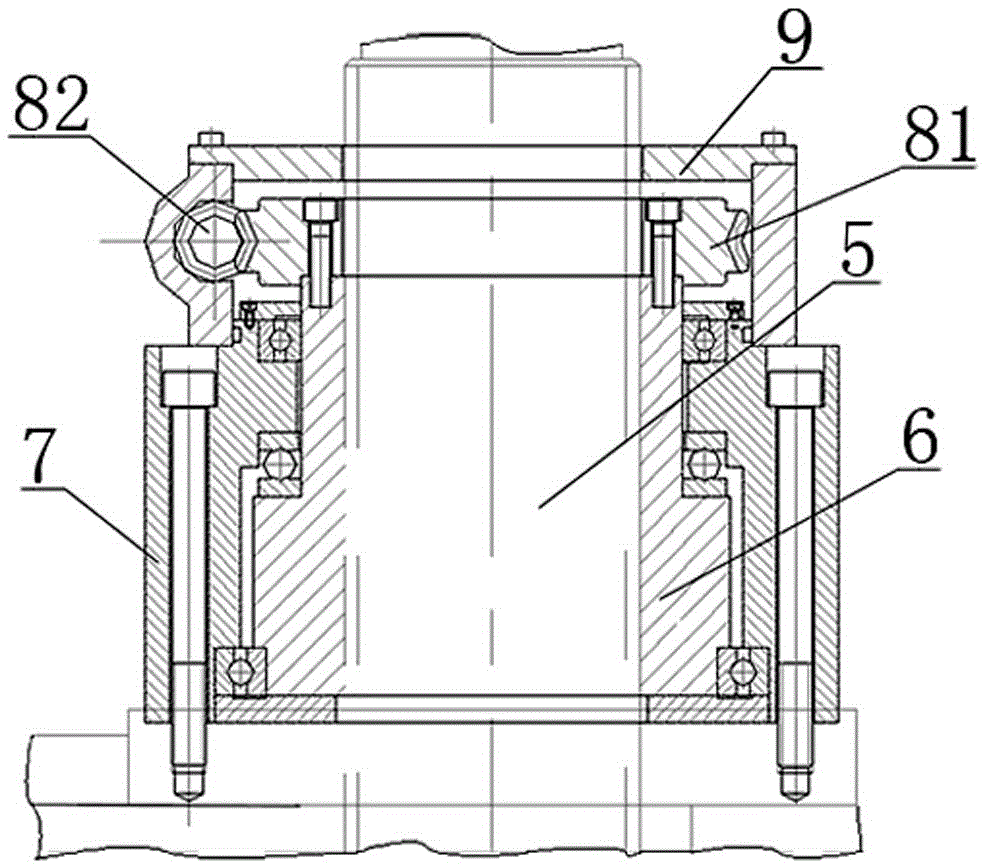

[0015] Refer to attached Figure 1-3 , an upper beam moving device for a hydraulic machine with a motor finale, which includes a mobile motor 1, a gear box 2, an upper beam 3, a transition shaft 4, a column 5, a column nut 6, a worm gear seat 7, a worm gear assembly 8, and four corners of the upper beam 3 The positions are respectively equipped with column 5, column nut 6 is equipped with column nut 6, worm gear seat 7 is equipped with column nut 6, worm wheel seat 7 and column nut 6 are rolled and matched, worm wheel seat 7 is fixed on the upper beam 3 by screws, column The nut 6 is equipped with a worm gear assembly 8, the mobile motor 1 is installed on the upper beam 3 between the two columns 5, the front end of the mobile motor 1 is connected to the middle of the gearbox 2, and the two ends of the gearbox 2 are respectively connected to the top of the column 5 through the transition shaft 4 The worm gear assembly8.

[0016] Lubricating device 9 is housed on described worm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com