Production process of forced air-cooled full sorbite vermicular graphite cast iron

A technology of compacted graphite cast iron and forced air cooling, which is applied in the production process of forced air-cooled full sorbite type compacted graphite cast iron, can solve the problems of difficulty in batch production and reduced product toughness, and achieve convenient operation, high hardness and low production cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

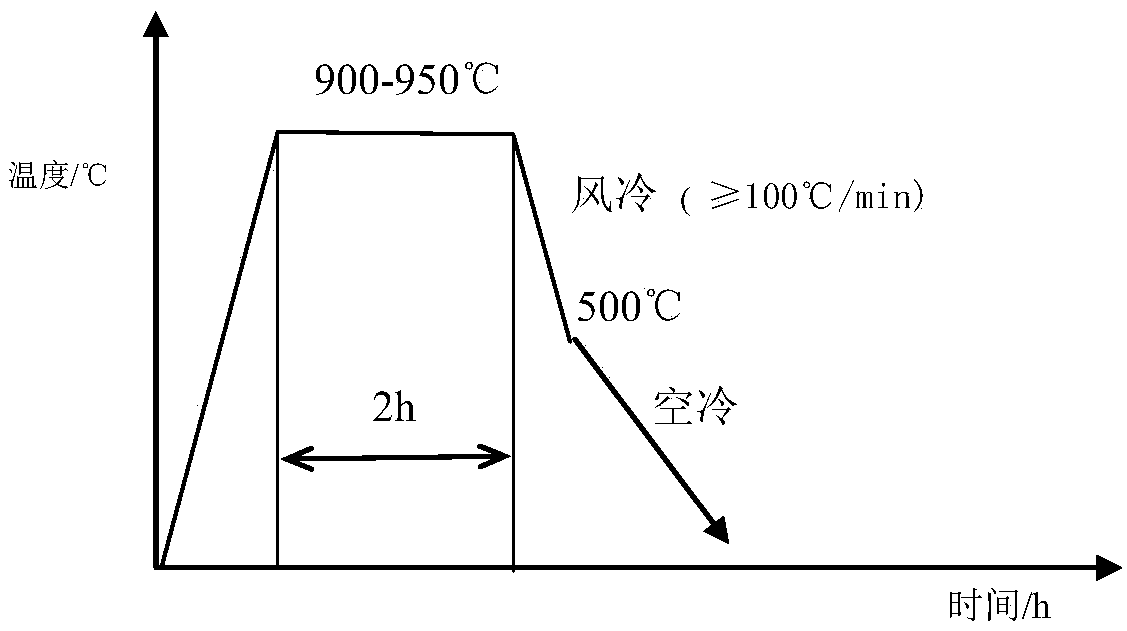

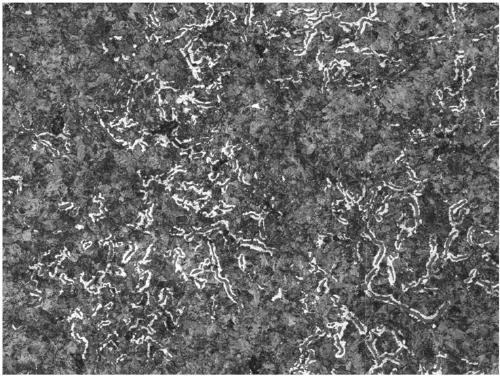

[0046] Example 1 (900°C×2h forced air cooling)

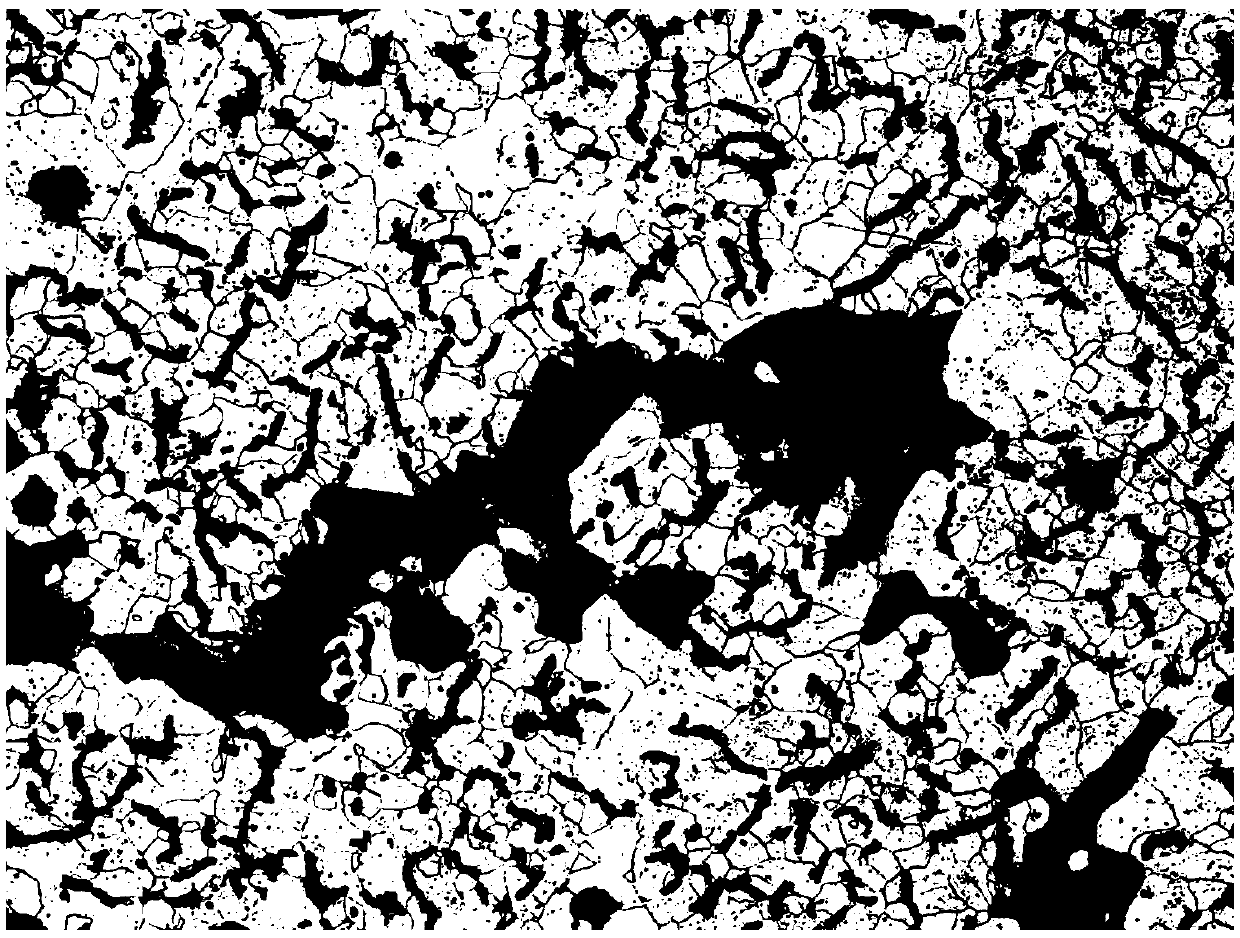

[0047] (1) Sample

[0048] The sample material used in the test is vermicular graphite cast iron with ferrite matrix in the original cast state, which meets the requirements of Table 2. The photo of its 1001 times metallographic structure is as follows: figure 2 shown by figure 2 It can be seen that the basic structure is ferrite + 10% coarse flaky pearlite + worm-like graphite.

[0049] (2) Heat treatment operation steps

[0050]First, raise the temperature of the heating furnace to 900±10°C for use. Then bind the vermicular graphite cast iron tensile test rod (size ф20×200mm) with iron wire and put it into the protective box (size 250×150×120mm) and fill it with granular charcoal, push the protective box into the heated In a heating furnace at 900°C, heat at this temperature for 2.0 hours at a constant temperature. After the heat penetration time, take the test rod out of the protective box in the heating furnace at 900...

Embodiment 2

[0058] Example 2 (930°C×2h forced air cooling)

[0059] (1) Sample

[0060] The compacted graphite cast iron workpiece is the ferrite matrix compacted graphite cast iron in the original cast state, and its composition meets the requirements in Table 2.

[0061] (2) Operation steps

[0062] First, raise the temperature of the heating furnace to 900±10°C for use. Then bind various vermicular graphite cast iron workpieces with iron wires and put them into a protective box and fill them with granular charcoal. Put the protective box into the furnace and heat it to 930°C, and heat at this temperature for 2.0 hours. After the heat penetration time, take the vermicular graphite cast iron workpiece out of the protective box in the heating furnace, hang it on the hanger quickly, and the distance between two adjacent workpieces is ≥ 150mm, then start the fan, and the two fans are respectively aligned with the hanging vermicular The direction of the graphite cast iron workpiece is blo...

Embodiment 3

[0070] Example 3 (950°C×2h forced air cooling)

[0071] (1) Sample

[0072] The composition of vermicular graphite cast iron with ferrite matrix in the original cast state of the vermicular graphite cast iron workpiece meets the requirements in Table 2.

[0073] (2) Operation steps

[0074] First, the resistance heating furnace was heated to 900°C for use. Then bundle the vermicular graphite cast iron workpiece with iron wire and put it into a protective box and fill it with granular charcoal. Put the box into the furnace and heat it to 950°C, and heat at this temperature for 2.0 hours. After the heat penetration time, take out various vermicular graphite cast iron workpieces from the protective box in the heating furnace, and quickly hang them on the hanger. The distance between two adjacent workpieces is ≥150mm, and then start the fan, and the two fans are aligned The direction of hanging the vermicular graphite cast iron workpiece is blown against (the air volume is 9500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com