Distilling method for reducing fusel oil in baijiu

A distillation method and fusel oil technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of unable to maintain the full and mellow quality of liquor, not suitable for the production and application of liquor enterprises, and heavy processing workload, and achieve a pure and elegant aroma. Conducive to enrichment and separation, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of liquor distillation method that reduces fusel oil content comprises the following steps:

[0035] (1) Pump the mature mash into the distillation preheating tank, heat up to 35-50°C and put it into the distillation retort;

[0036] (2) Turn on the direct steam to 0.6MPa until the temperature inside the retort reaches 90°C, turn off the steam to 0.3MPa;

[0037] (3) False wine heads are discharged after the wine is released, and the wine heads are collected when the measured alcohol content reaches 60%;

[0038] (4) After collecting 10% of the volume of base wine A, turn the valve to the base wine tank, and return the direct steam to 0.6MPa; (5) After collecting 90% of the volume of base wine A, turn off the steam;

[0039] Divide the 10% volume base wine A head (58.5% V / V) into two parts, one part is directly mixed with the base wine A body in proportion, and blended to become a control sample.

[0040] Another portion of base wine A wine head continues the f...

Embodiment 2

[0059] A kind of liquor distillation method that reduces fusel oil content comprises the following steps:

[0060] (1) Pump the mature mash into the preheating tank, heat up to 35-45°C and put it into the distillation retort;

[0061] (2) Turn on direct steam to 0.5MPa until the temperature inside the retort reaches 88°C, turn off the steam to 0.3MPa;

[0062] (3) False wine heads are discharged after the wine is discharged, and the wine heads are collected when the measured liquor degree reaches 59%;

[0063] (4) After collecting 20% of the volume of the base wine B head, turn the valve to the base wine tank, and adjust the direct steam back to 0.5 MPa;

[0064] (5) After collecting 80% of the volume of base wine B, turn off the steam;

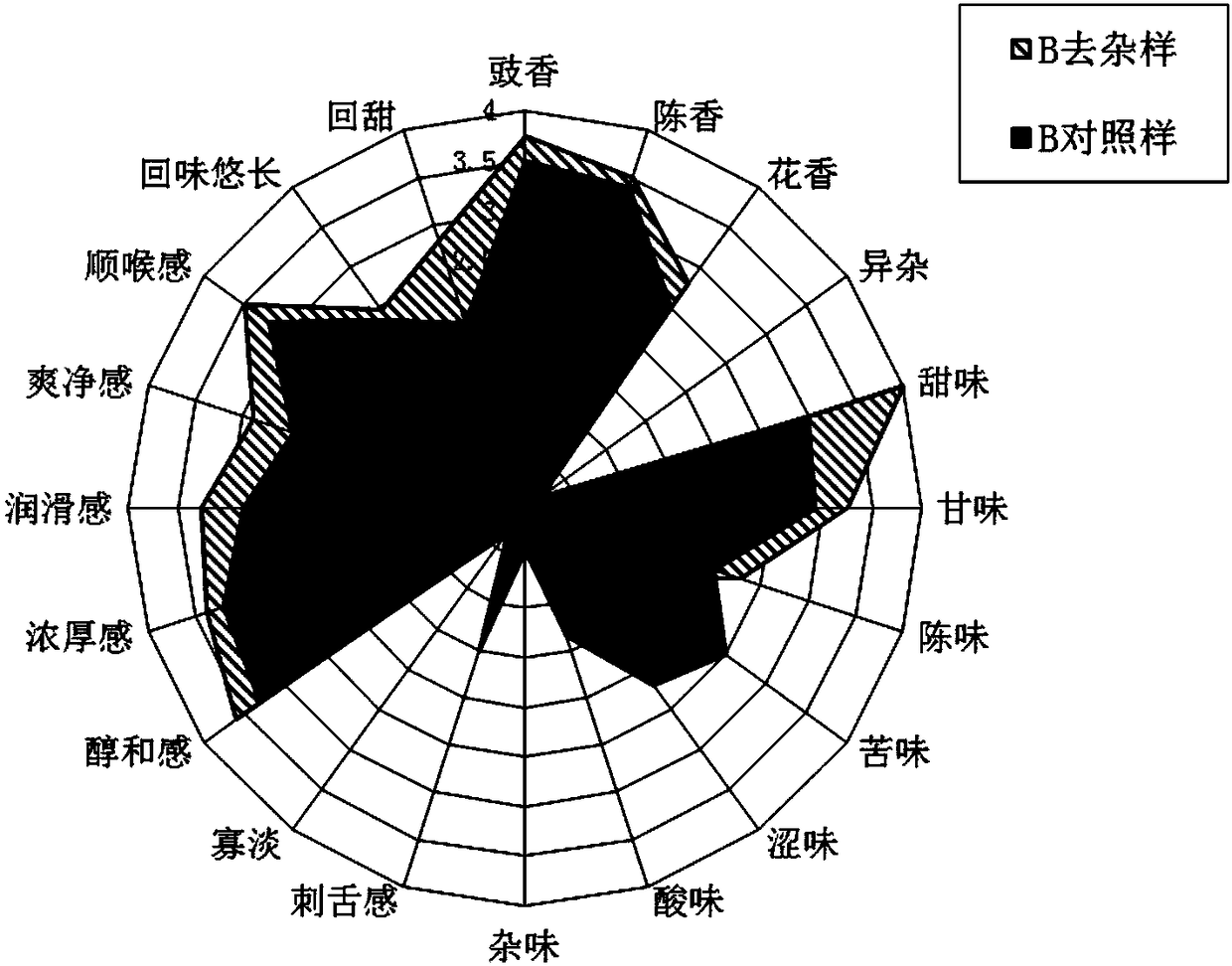

[0065] Divide 20% volume of the base wine B head (56% V / V alcohol content) into two parts, one part is directly mixed with the base wine B body in proportion, and blended to become a control sample.

[0066] Another portion of base wine ...

Embodiment 3

[0085] A kind of liquor distillation method that reduces fusel oil content comprises the following steps:

[0086] (1) Pump the mature mash into the preheating tank, heat up to 25-40°C and put it into the distillation retort;

[0087] (2) Turn on the indirect steam to 0.4MPa until the temperature inside the retort reaches 92°C, then turn off the steam to 0.2MPa;

[0088] (3) False wine heads are discharged after the wine is released, and the wine heads are collected when the measured liquor degree reaches 65%;

[0089] (4) After collecting 30% of the volume of the base wine C head, turn the valve to the base wine tank, and adjust the direct steam back to 0.4MPa;

[0090] (5) After collecting 70% of the volume of base wine C wine, turn off the steam;

[0091] Divide 30% volume of base wine C head (60% V / V alcohol content) into two parts, one part is directly mixed with base wine C body in proportion, and blended to become a control sample.

[0092] Another portion of base wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com