Kiwifruit light type dry wine and preparation method thereof

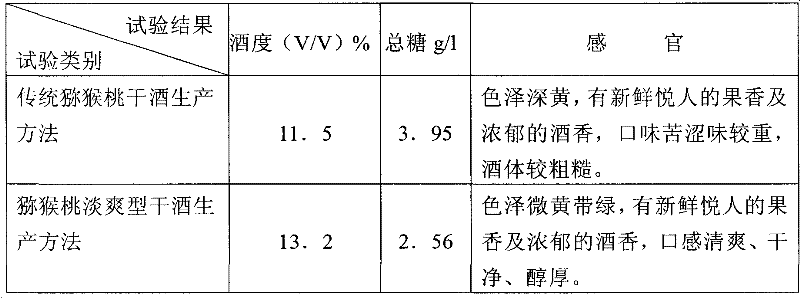

A technology of kiwi fruit, light and refreshing type, which is applied in the field of brewing kiwi fruit light and refreshing dry wine, which can solve the problems that the taste of kiwi fruit wine cannot be improved, the recovery rate cannot be improved, and the taste of the wine is bitter and rough, so as to achieve a refreshing taste and a high yield. The effect of increasing the rate and increasing the rate of income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention uses biological brewing technology to prepare kiwi fruit light dry wine with kiwi fruit and malt syrup as main raw materials. The present invention will be further described below in conjunction with embodiment, but does not limit the present invention.

[0024] 1. Kiwi light dry wine

[0025] The kiwi light dry wine is mainly made of 10-20% of malt syrup and 80-90% of kiwi pulp from which dregs have been removed by weight; 0.05-0.1g of yeast needs to be added during the preparation process / kg, pectinase 0.05~0.1g / kg and sulfur dioxide 0.1~0.2g / kg, wherein, yeast and pectinase precipitated by themselves after fermentation and were completely removed after filtration, and sulfur dioxide volatilized during the fermentation process.

[0026] The kiwi light dry wine is preferably made from the following raw materials: by weight, the wine is mainly made of 90% kiwi pulp and 10% malt syrup; Gelase 0.1g / kg and sulfur dioxide 0.2g / kg, wherein, yeast and pectina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com