Tea extract and preparation method thereof

A technology of tea extract and theanine, applied in the directions of tea extraction, food preparation, food science, etc., can solve the problems of neglect and achieve the effect of resource utilization, better efficacy and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

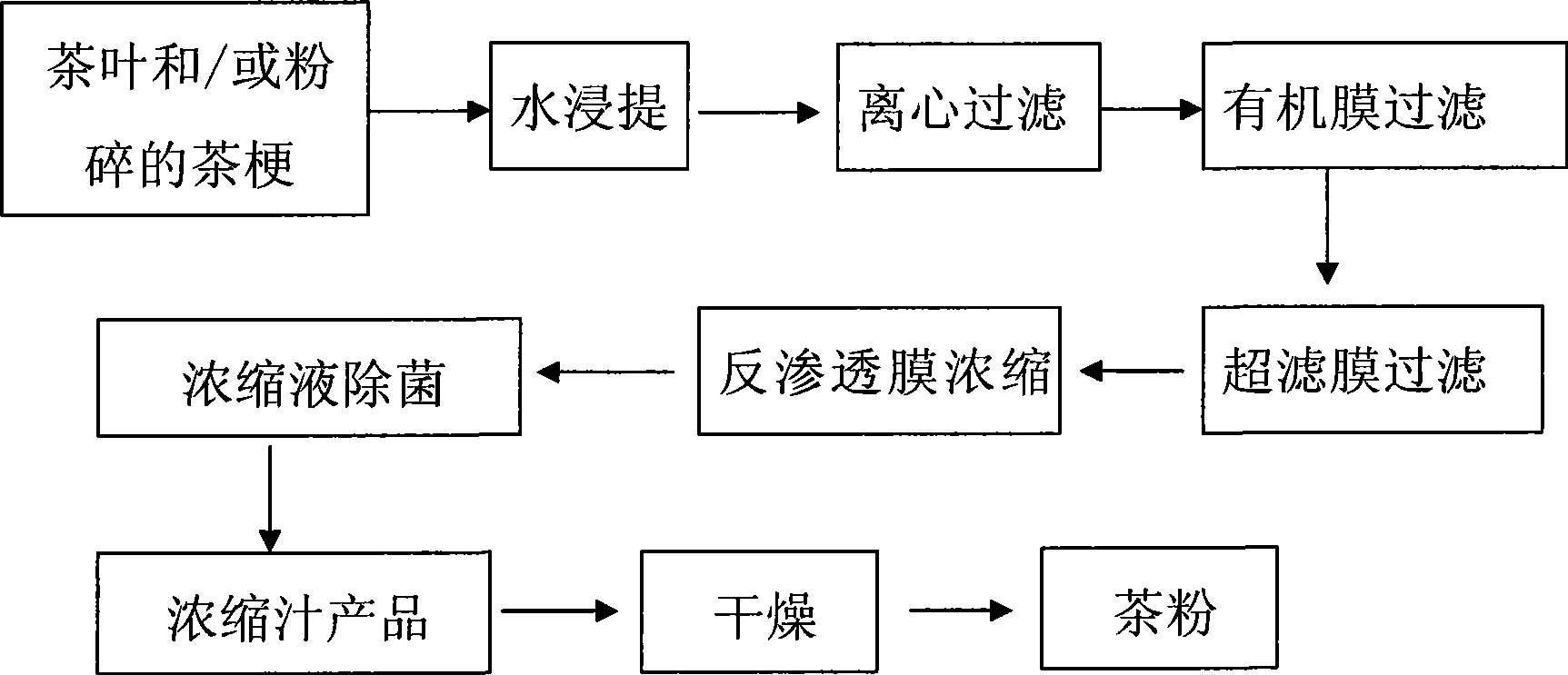

Method used

Image

Examples

Embodiment 1

[0048] 50 kg of green tea leaves (theanine content is 1wt%) and 150 kg of green tea stems, crushed to a particle size of 0.1-0.3mm and placed in a 3-ton multi-functional extraction tank, add 2000 liters of pure water, stir and extract at 30°C After 30 minutes, filter; add 1000 liters of pure water to the filter residue, stir and extract at 30°C for 15 minutes, and filter. The two filtrates were combined, high-speed tubular centrifugation (14000 rpm), filtered, and the filtrate was filtered through a tubular PVDF tubular organic membrane (AQU250-B10, 0.22 μm). The filtrate is filtered through a PVDF ultrafiltration membrane with a molecular weight cut-off of 5000 Daltons, and the ultrafiltration membrane permeate is concentrated through a reverse PA osmosis membrane (DOW FILMTEC BW30LE-400) to obtain 80 liters of concentrated juice with a solid content of 30 wt%. Centrifugal filtration, organic membrane filtration, ultrafiltration membrane filtration and reverse osmosis membran...

Embodiment 2

[0051] 100 kg of green tea leaves (theanine content is 1wt%) and 100 kg of green tea stems, crushed to a particle size of 0.9-1.1 mm, placed in a 3-ton multifunctional extraction tank, added with 3000 liters of pure water, and stirred at 20 ° C After leaching for 60 minutes, filter; add 1,000 liters of pure water to the filter residue, leaching for half an hour at 20°C, and filter; the two filtrates are combined, filtered by high-speed tubular centrifugal (10,000 rpm), and the filtrate is passed through a polypropylene membrane (PP) Tubular organic membrane (Hefei Fengyun Technology Co., Ltd. HY-MF-10000, 0.1 μm) filtration, the filtrate flows through a chromatographic column filled with 100 kg of macroporous adsorption resin Diaion HP-20, and the effluent passes through a molecular weight cut-off range of 3000 It is filtered by the ultrafiltration membrane (PS) of polysulfone, and the permeate of the ultrafiltration membrane is then concentrated by a polypiperazine amide compo...

Embodiment 3

[0054] 300 kg of green tea stems (theanine content is 1.4wt%), crushed to a particle size of 1.0-3.0 mm, placed in a 3-ton multifunctional extraction tank, added 1500 liters of pure water, stirred and extracted at 70 ° C for 20 minutes Finally, filter; add 1500 liters of pure water to the filter residue, leaching for 10 minutes at 50°C, and filter; the two filtrates are combined and filtered by high-speed tubular centrifugation (12000 rpm), and the filtrate is passed through a PVDF tubular organic membrane (GE Desal MembraneAG 8080F ) filtration, the filtrate flows through the Rohm and Haas AMBELITE XAD-1600 chromatographic column filled with 300 kg of macroporous adsorption resin, and the effluent is filtered by a polysulfone ultrafiltration membrane (PS) with a molecular weight cut-off range of 1000 Daltons, and the ultrafiltration membrane The permeate is then concentrated through a PA reverse osmosis membrane (DOW FILMTECBW30LE-400) to obtain 120 liters of concentrated juic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com