Method for improving ferment distilled spirit degree by distilling with vinasse

A technology of fermenting wine and fermentation temperature, which is applied in the field of wine making, can solve problems such as waste of raw materials and environmental impact, and achieve the effect of reducing pollution and improving nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

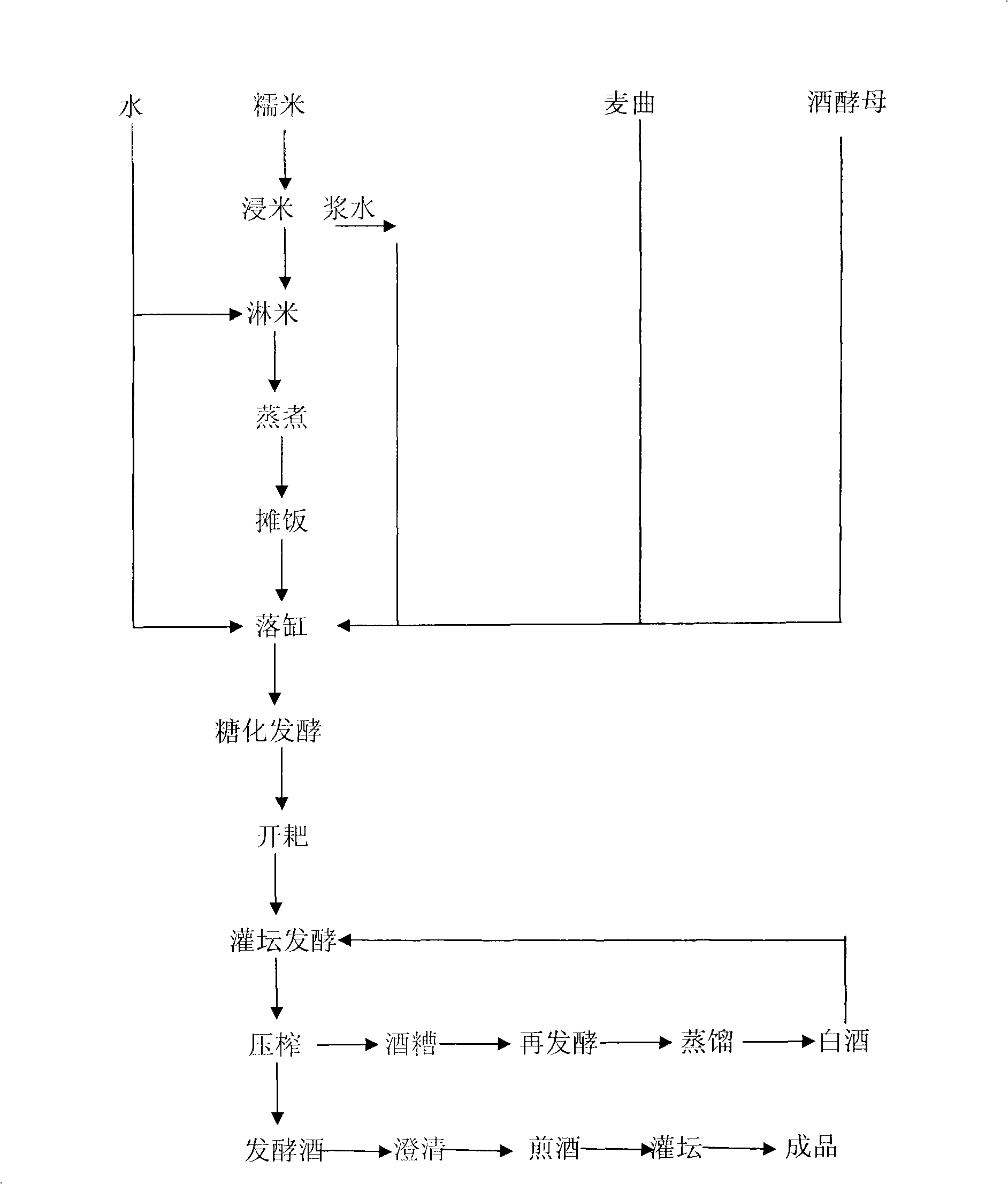

[0009] Such as figure 1 As shown, glutinous rice is used as raw material, soaked in water at 25-30°C for 24-27 hours, the water absorption is controlled between 25-30%, and the process of soaking and drenching rice is completed, and then steamed for 15-15 hours under normal pressure. For 30 minutes, the rice is required to be "hard on the outside and soft on the inside, without white heart inside, loose and not mushy, transparent but not rotten, and uniform." After spreading the rice, put it into the vat. The temperature in the vat is controlled at 23-26°C. Add wheat koji and wine yeast for saccharification and fermentation. It can be opened at 4-7°C. After 57 days of saccharification and fermentation, the post-fermentation period is entered into the post-fermentation period. During the post-fermentation period, the temperature is controlled at 13-15°C and the time is 25-35 days. 20°-30° fermented wine, the fermented wine is clarified, decocted, and poured into the altar to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com