Radial elastic loading device for skew rolling bar

An elastic and bar technology, which is applied in the direction of guiding/positioning/alignment devices, metal rolling, metal rolling, etc., can solve the problems of high noise in the production site, low device rigidity, and reduced efficiency, so as to reduce the noise on site , High rigidity and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

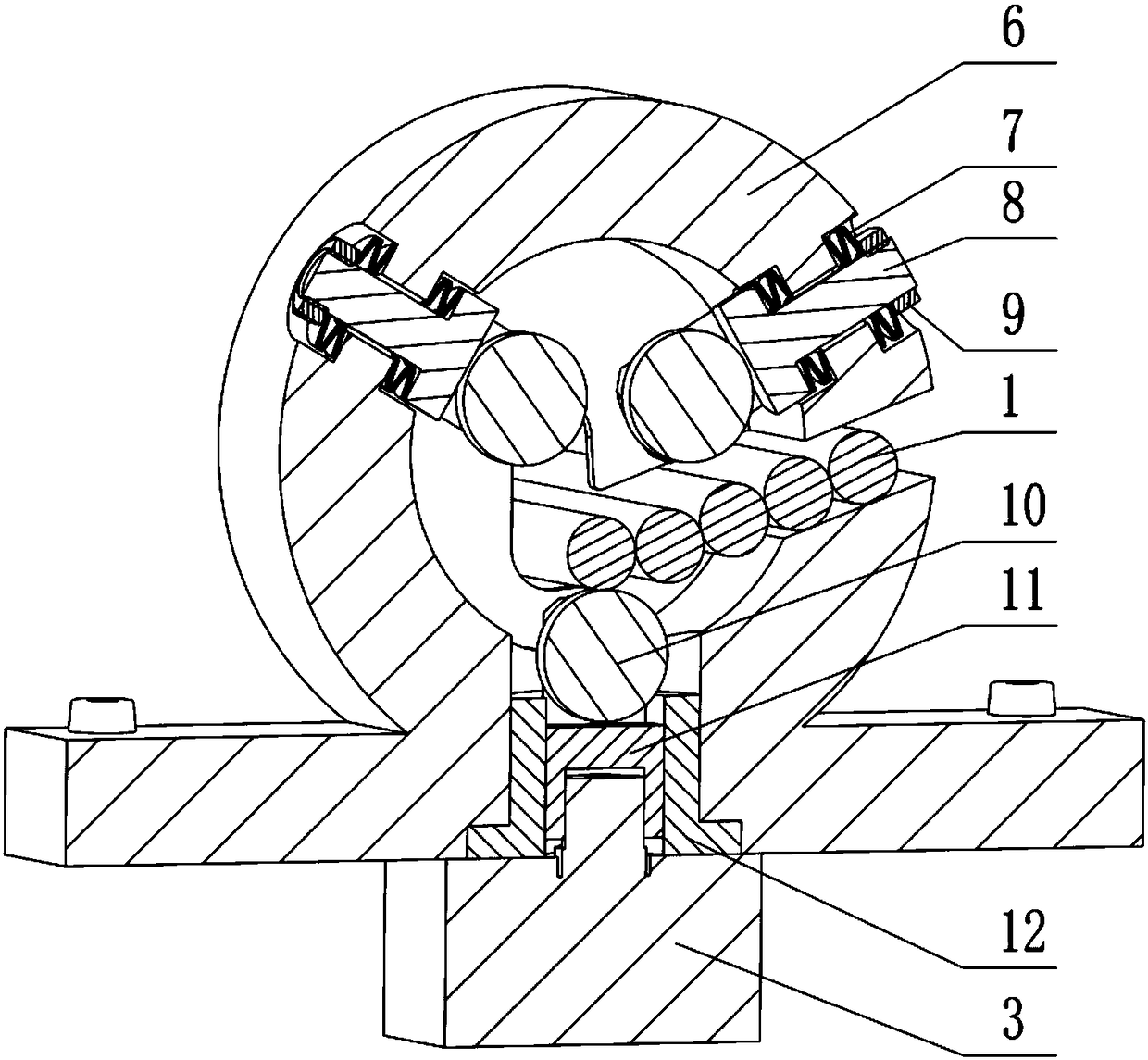

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with specific drawings. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be regarded as isolated, and they can be combined with each other to achieve better technical effects. In the drawings of the following embodiments, the same reference numerals appearing in each drawing represent the same features or components, which can be applied in different embodiments.

[0029] The following are preferred embodiments of the present invention. It should be noted that the specific parameters in the embodiments can be determined according to actual needs, and are not intended to limit the present invention. The protection scope of the present invention shall be determined by the claims.

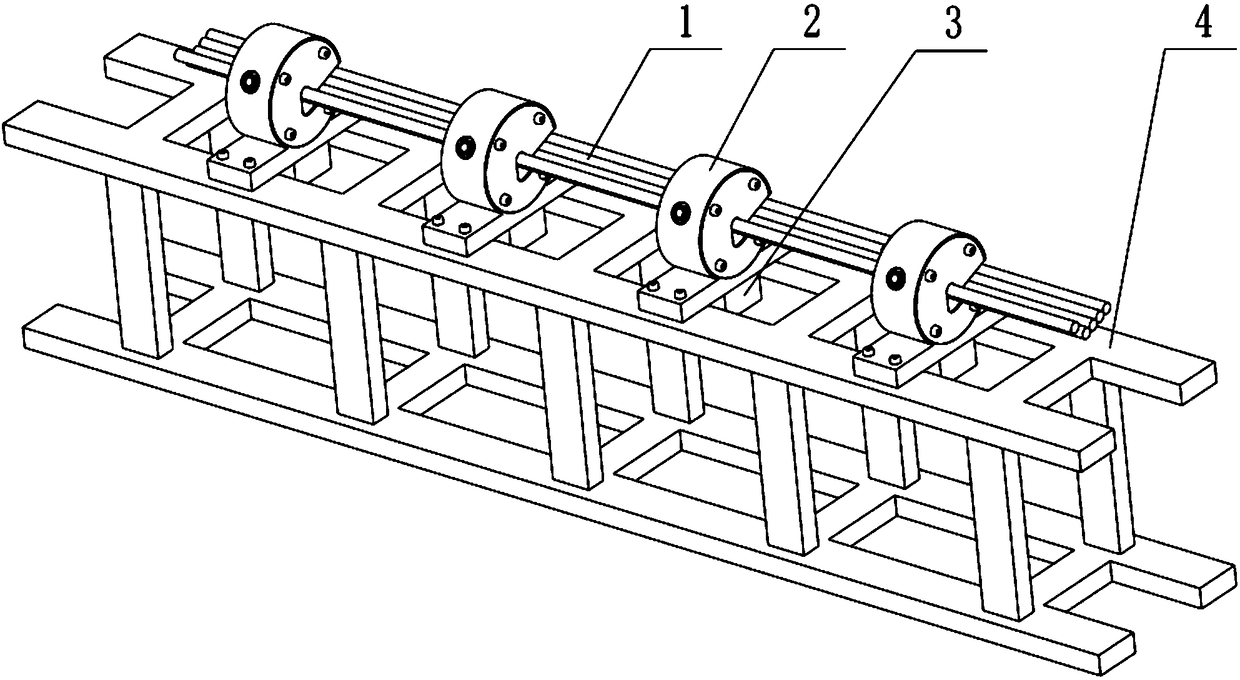

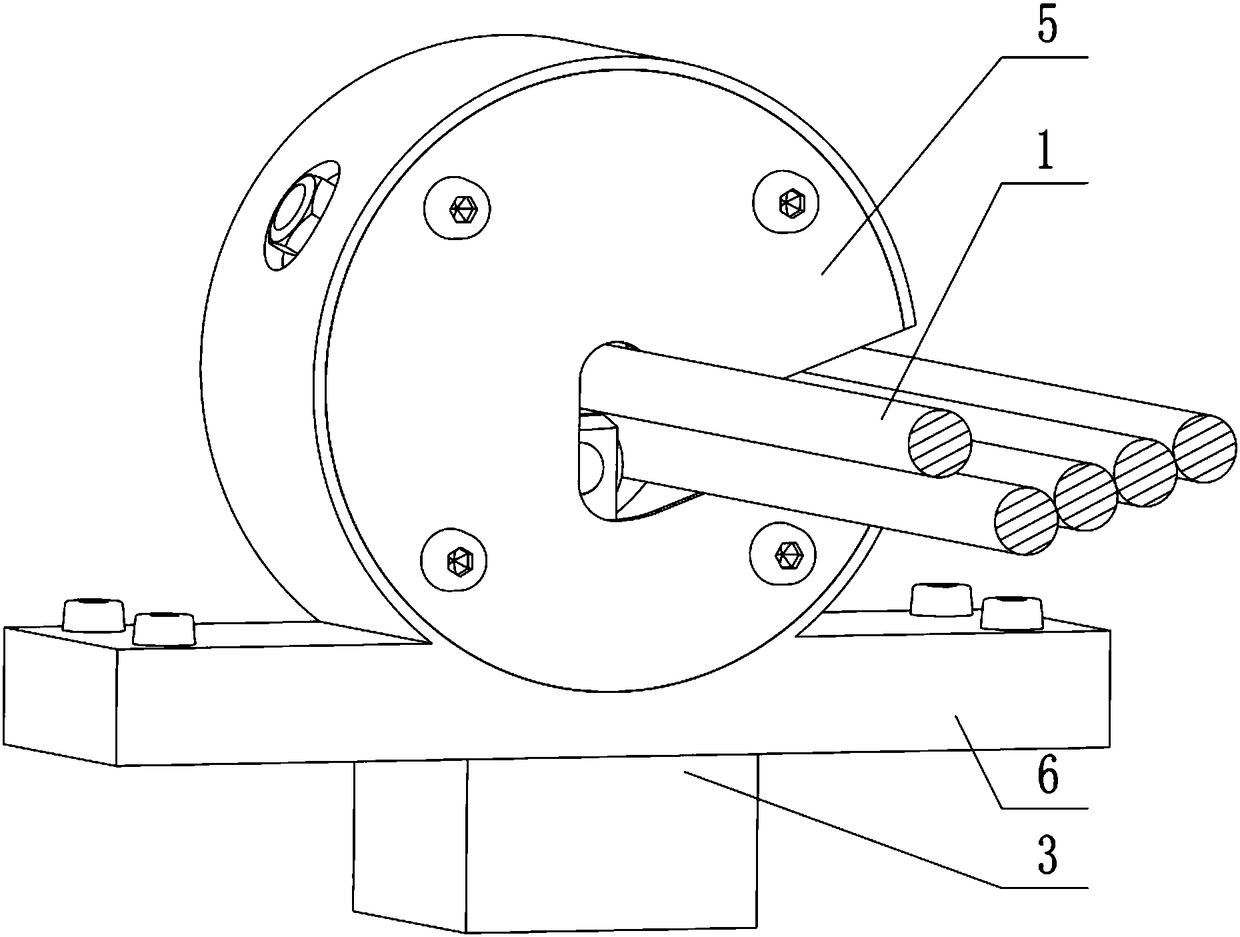

[0030] Such as figure 1 , 2 As shown, a bar 1 with a length of 3000 mm and a diameter of Φ25 mm is cross-rolled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com