Full-automatic spraying device for wind power bolts, and working method thereof

A technology for wind power bolts and spraying equipment, which is applied to coatings, spraying devices, and devices for coating liquid on surfaces, etc., can solve the problems of large volume, hidden safety hazards, and poor uniformity of wind power bolts, so as to avoid uneven spraying and spraying. Even, easy-glide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

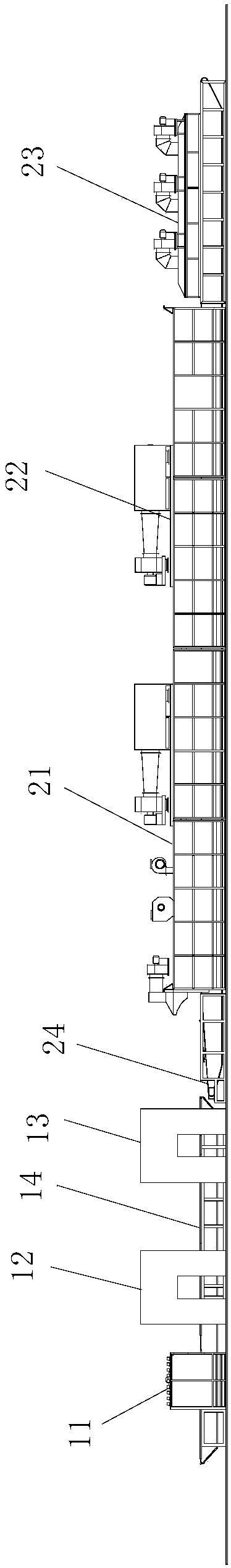

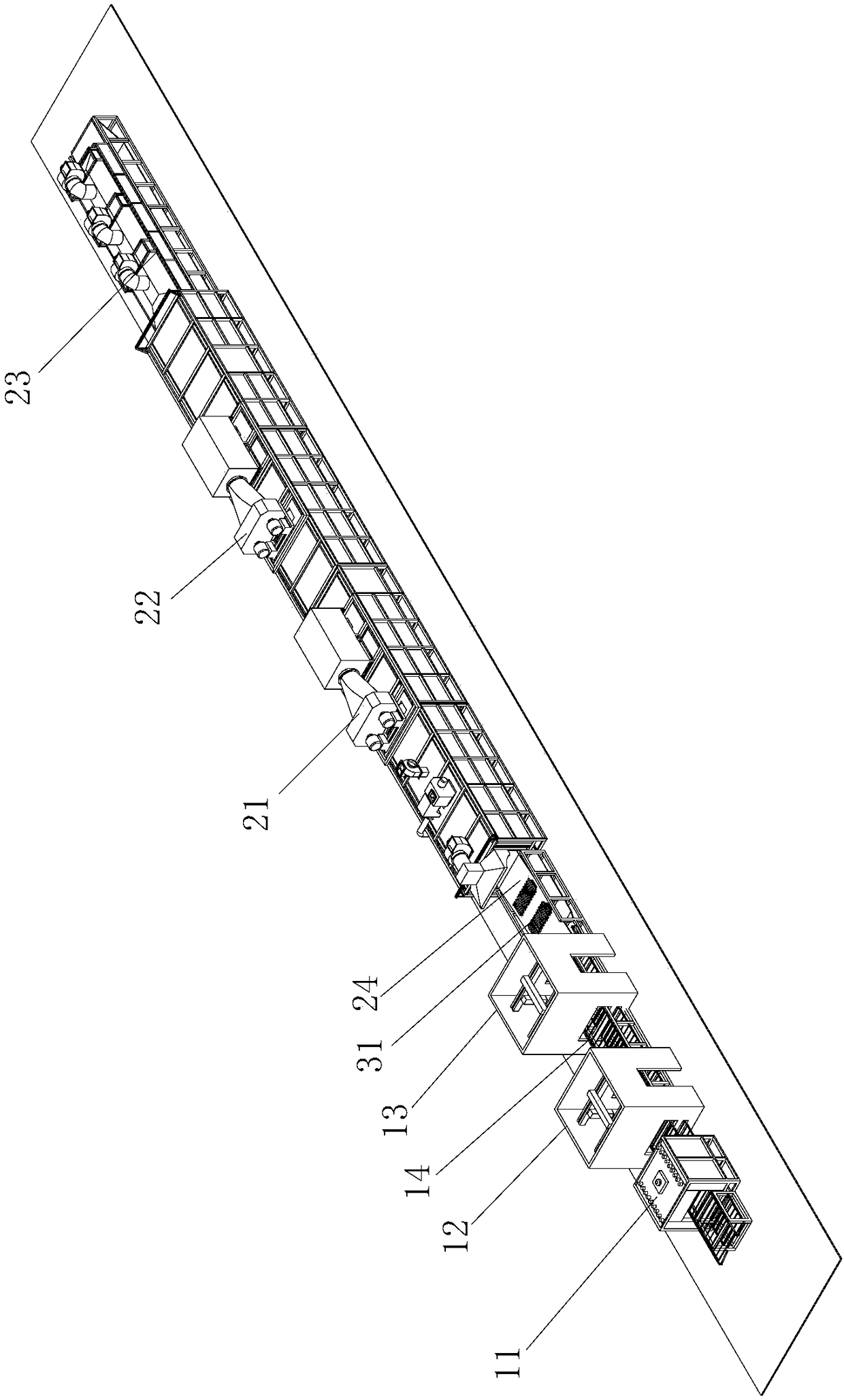

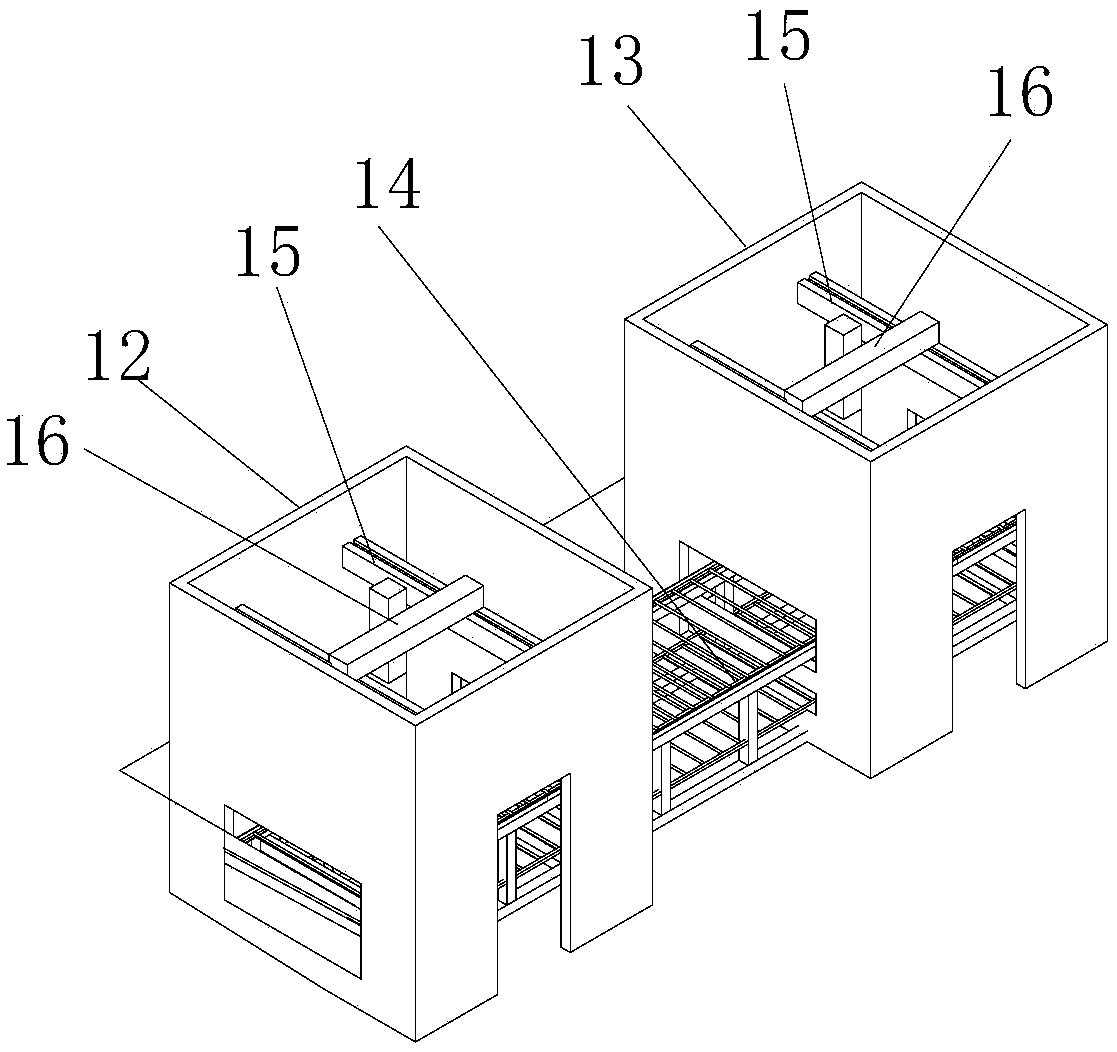

[0026] Example 1 as Figure 1 to Figure 2 As shown, the fully automatic spraying equipment for wind power bolts in this embodiment includes a preheating furnace 11, a first spraying device 12, a second spraying device 13, and a sintering furnace arranged in sequence, and the first conveyor network is arranged in the hearth of the preheating furnace 11. Belt 14, the first conveyor belt 14 passes through the preheating furnace 11 and extends to the bottom of the first spraying device 12 and the second spraying device 13, so as to spray the wind power bolts 31 preheated by the preheating furnace 11 ; The second conveyor belt 24 is set through the hearth of the sintering furnace, and the outlet of the first conveyor belt 14 is connected with the entrance of the second conveyor belt 24; as image 3 As shown, the first spraying device 12 comprises a spraying room, the first conveyor belt 14 passes through the spraying room and is provided with a slide rail 15 perpendicular to the fi...

Embodiment 2

[0029] A fully automatic spraying method for wind power bolts, comprising the following steps:

[0030] Step A, put the wind power bolt 31 to be sprayed on the material rack, the zigzag support plate 33 is in the initial state, the flat top 331 of the zigzag support plate 33 coincides with the concave wave trough 322 of the square wave support plate 32, multiple wind power The bolts 31 are sequentially arranged on the flat tops 331 of each zigzag support plate 33 .

[0031] Step B: Turn on the preheating furnace 11, place the material rack on the first conveyor belt 14 and pass through the preheating furnace 11, so that the surface temperature of the wind power bolt 31 after passing through the preheating furnace 11 is 45 to 55°C, and perform preheating. heat treatment.

[0032] Step C, the material rack on the first conveyor belt 14 and the wind power bolt 31 pass under the first spraying device 12, and the spray head 16 of the first spraying device 12 moves back and forth on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com