A kind of preparation method and obtained product of iron ion-doped carbon nitride nanotube

A carbon nitride and iron ion technology is applied in the preparation of carbon nitride nanotubes and the preparation of ion-doped carbon nitride, which can solve the problems of uneven ion doping and easy oxidation of doped ions, and achieve high Reactivity, improved separation and transfer, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1.1 Reflux 2 g of melamine and 100 ml of deionized water at 100 °C until the melamine is completely dissolved to obtain an aqueous solution of melamine.

[0034] 1.2 Make anhydrous ferric chloride into ferric chloride aqueous solution with a concentration of 0.02 g / ml, add 100 microliters of ferric chloride aqueous solution into melamine aqueous solution, and reflux at 100°C for 30 min under stirring to make melamine and ferric chloride Mix well.

[0035] 1.3 Lower the temperature of the solution in 1.2 above in stages. The specific operation is: lower the temperature of the solution in 1.2 above 100°C at a cooling rate of 1°C / min until it drops to room temperature. During the cooling process, crystals gradually precipitate.

[0036] 1.4 After the crystallization is complete, the precipitated crystals are taken out from the solution, and the solution on the crystals is blotted dry on filter paper to obtain iron-doped melamine crystals.

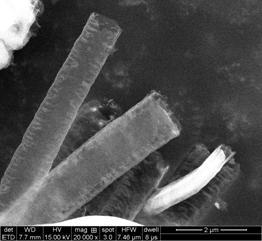

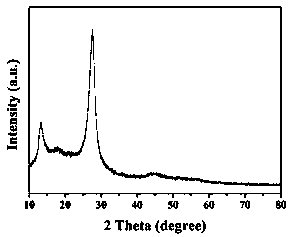

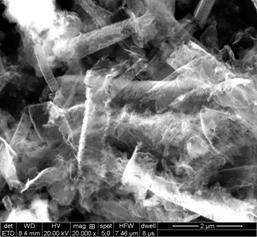

[0037] 1.5 The iron-doped melam...

Embodiment 2

[0042] 2.1 Reflux 2 g of melamine and 100 ml of deionized water at 100 °C until the melamine is completely dissolved to obtain an aqueous solution of melamine.

[0043]2.2 Make anhydrous ferric chloride into ferric chloride aqueous solution with a concentration of 0.02 g / ml, add 500 microliters of ferric chloride aqueous solution into melamine aqueous solution, and reflux at 100°C for 30 min under stirring to make melamine and ferric chloride Mix well.

[0044] 2.3 Lower the temperature of the solution in 2.2 above in stages. The specific operation is: lower the temperature of the 100°C solution in 2.2 above at a cooling rate of 1°C / min until it drops to room temperature. During the cooling process, crystals gradually precipitate.

[0045] 2.4 After the crystallization is complete, the precipitated crystals are taken out from the solution, and the solution on the crystals is blotted dry on filter paper to obtain iron-doped melamine crystals.

[0046] 2.5 The iron-doped melami...

Embodiment 3

[0050] 3.1 Reflux 2 g of melamine and 100 ml of deionized water at 100 °C until the melamine is completely dissolved to obtain an aqueous solution of melamine.

[0051] 3.2 Make anhydrous ferric chloride into ferric chloride aqueous solution with a concentration of 0.02 g / ml, add 1 ml of ferric chloride aqueous solution into melamine aqueous solution, and reflux at 100°C for 30 min under stirring to fully dissolve melamine and ferric chloride. well mixed.

[0052] 3.3 Lower the temperature of the solution in 3.2 above in stages. The specific operation is: lower the temperature of the 100°C solution in 3.2 above at a cooling rate of 1°C / min until it drops to room temperature. During the cooling process, crystals gradually precipitate.

[0053] 3.4 After the crystallization is complete, the precipitated crystals are taken out from the solution, and the solution on the crystals is blotted dry on filter paper to obtain iron-doped melamine crystals.

[0054] 3.5 The iron-doped mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com