A kind of preparation method of light-emitting diode epitaxial wafer

A technology of light-emitting diodes and epitaxial wafers, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of reducing the luminous efficiency of light-emitting diodes, affecting the recombination efficiency of electrons and holes, and poor growth quality of multiple quantum well layers. Polarization effect, luminous efficiency improvement, stress relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

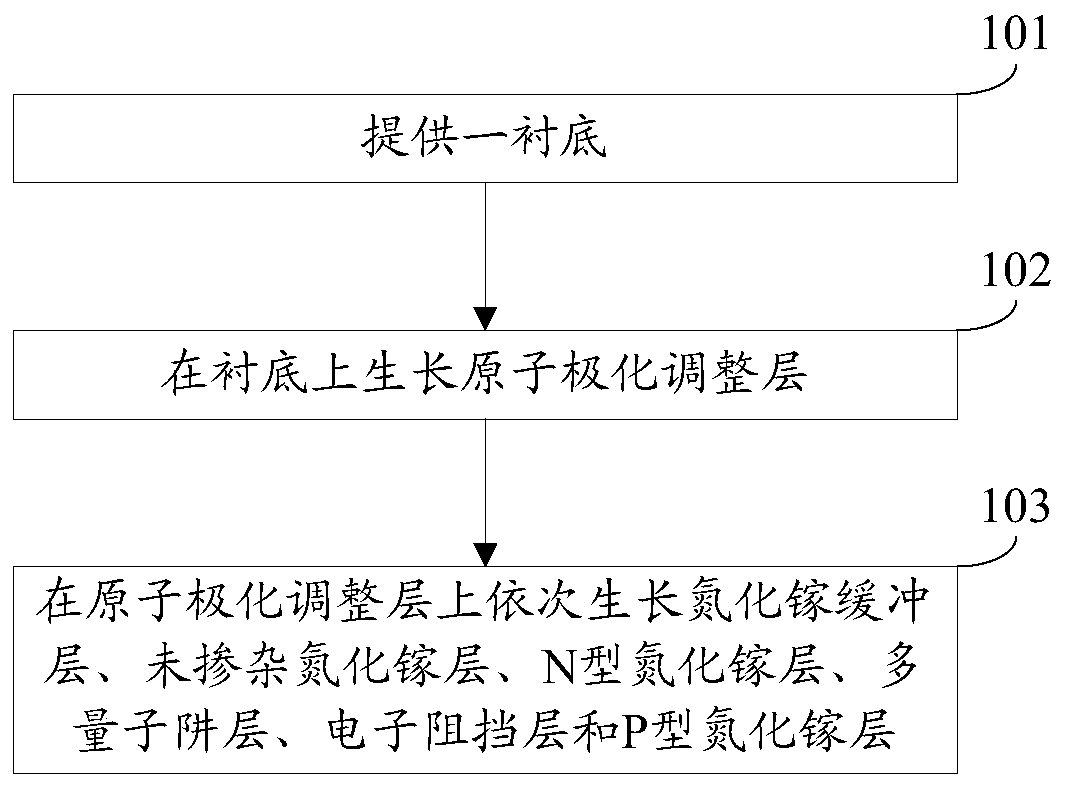

[0035] The embodiment of the present invention provides a method for preparing a light-emitting diode epitaxial wafer, figure 1 For the flow chart of the preparation method provided by the embodiments of the present invention, see figure 1 , the preparation method comprises:

[0036] Step 101: Provide a substrate.

[0037] Optionally, this step 101 may include:

[0038] An aluminum nitride film is formed on a sapphire substrate by using a physical vapor deposition (English: Physical Vapor Deposition, PVD for short) technique.

[0039] The aluminum nitride thin film is preformed on the sapphire substrate by PVD technology, and the subsequent atomic polarization adjustment layer is grown on the aluminum nitride thin film, which is beneficial to the growth of the atomic polarization adjustment layer and improves the growth quality of the epitaxial wafer.

[0040] Step 102: growing an atomic polarization adjustment layer on the substrate.

[0041] In this embodiment, the atomi...

Embodiment 2

[0069] An embodiment of the present invention provides a method for preparing a light-emitting diode epitaxial wafer, and the preparation method provided in this embodiment is a specific realization of the preparation method provided in Embodiment 1. Specifically, the preparation method includes:

[0070] Step 200: Treat the surface of the substrate with ammonia gas.

[0071] Step 201: controlling the temperature to 1200° C., the pressure to 200 Torr, and the V / III ratio to 1200, using ammonia gas and trimethylaluminum to grow an atomic polarization adjustment layer with a thickness of 100 nm.

[0072] Step 202 : controlling the temperature to 500° C. and the pressure to 500 Torr, growing a gallium nitride buffer layer with a thickness of 100 nm on the atomic polarization adjustment layer.

[0073] Step 203: Control the temperature to 1050° C. and the pressure to 300 Torr, and grow an undoped GaN layer with a thickness of 1 μm on the GaN buffer layer.

[0074] Step 204: Cont...

Embodiment 3

[0083] The embodiment of the present invention provides a method for preparing a light-emitting diode epitaxial wafer, and the preparation method provided in this embodiment is another specific realization of the preparation method provided in the first embodiment. The preparation method provided in this example is basically the same as that provided in Example 2, except that, in this example, the growth temperature of the atomic polarization adjustment layer is 1100° C., and the V / III ratio is 400.

[0084] Experiments have found that compared with Example 2, the beneficial effect is increased by about 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com