Hub driving system all-in-one integration optimization design method

A hub-driven, optimized design technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as deterioration of vehicle ride comfort and ride comfort, conflicts between power/torque density and cooling constraints, and reduce the design space range, increased design efficiency, and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

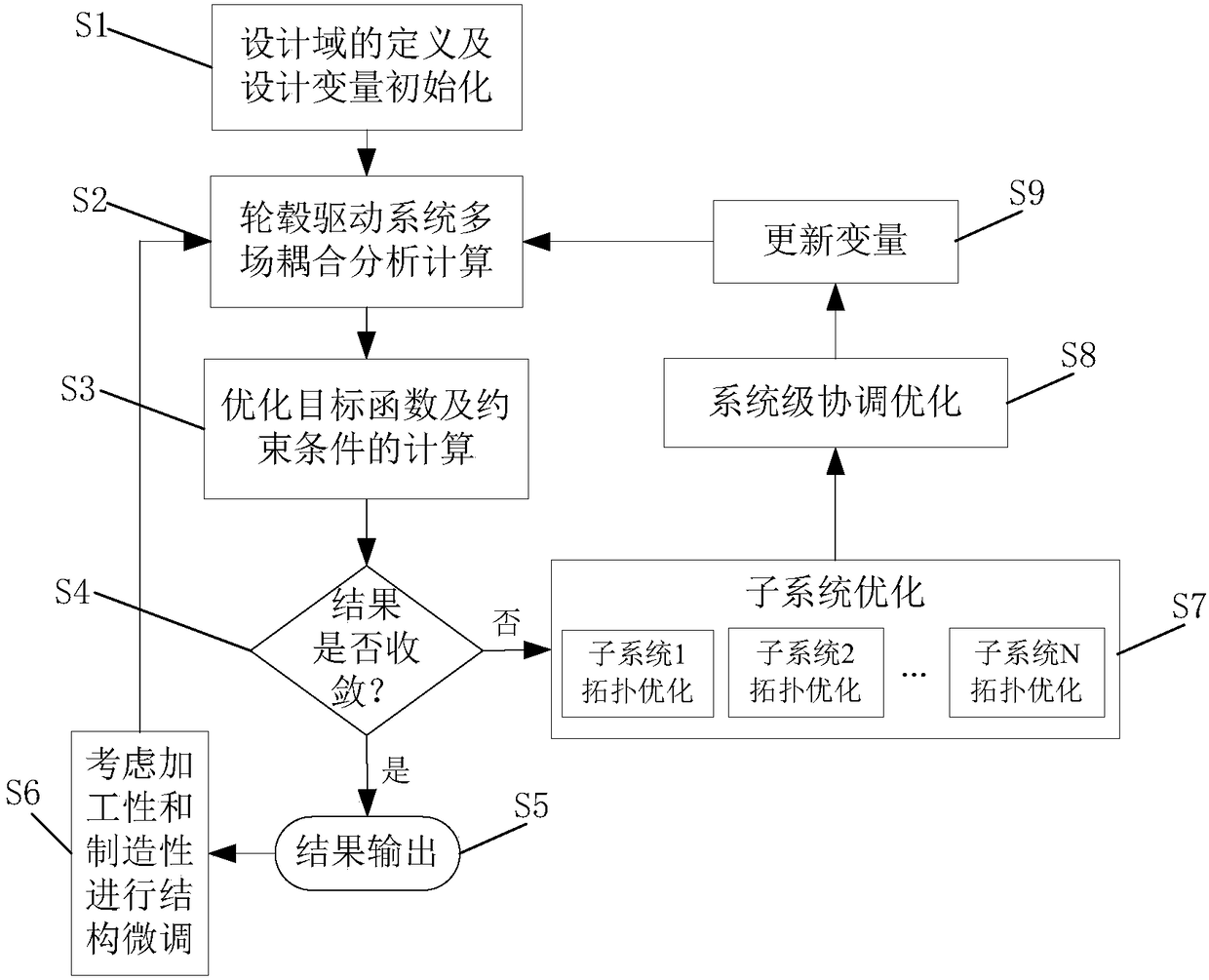

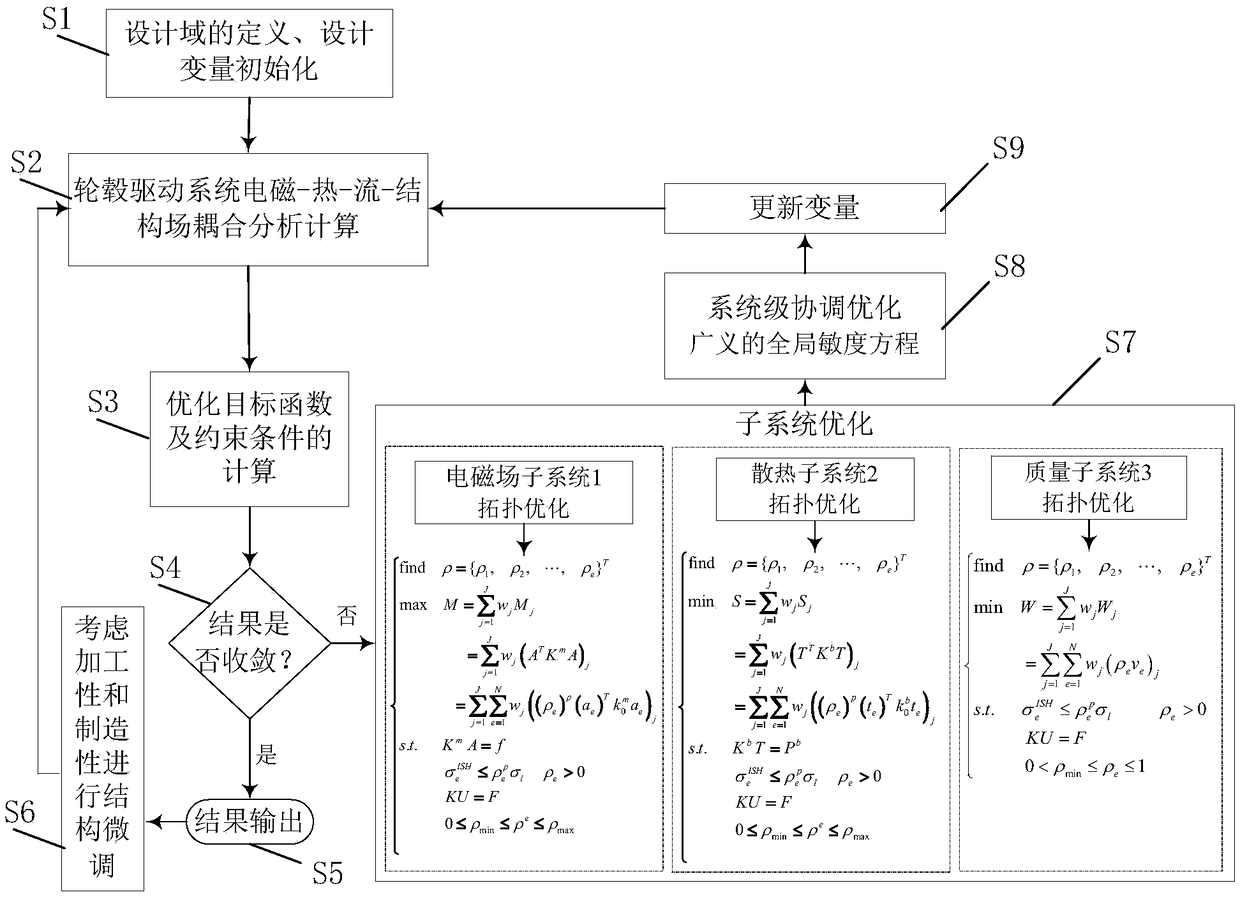

[0013] Such as figure 2 Shown: The electromagnetic domain of the hub drive system is used as the design domain for optimization design, and the optimization goal is to maximize the torque density, maximize the heat dissipation performance and minimize the mass of the hub drive system. Its steps include:

[0014] S1: First, define the design domain and initialize the design variables. The electromagnetic domain of the in-wheel motor drive system is defined as the design domain and the density of imaginary material elements is initialized. The electromagnetic design domain mainly refers to the related components of the in-wheel motor, which involves the coupling of electromagnetic-thermal-flow-structural fields.

[0015] S2: After the information initialization is completed, use the multi-field coupling analysis model (platform) to conduct electromagnetic-thermal-fluid-structure field coupling analysis and calculation in the design domain of the in-wheel motor drive system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com