Retaining structure impact load simulation test device and method

A support structure and simulation test technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of large test loading device and test model, inconvenient structural model modification and production, and inability to simulate the impact of support structures. Achieve the effect of convenient and quick installation, simple structure and small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

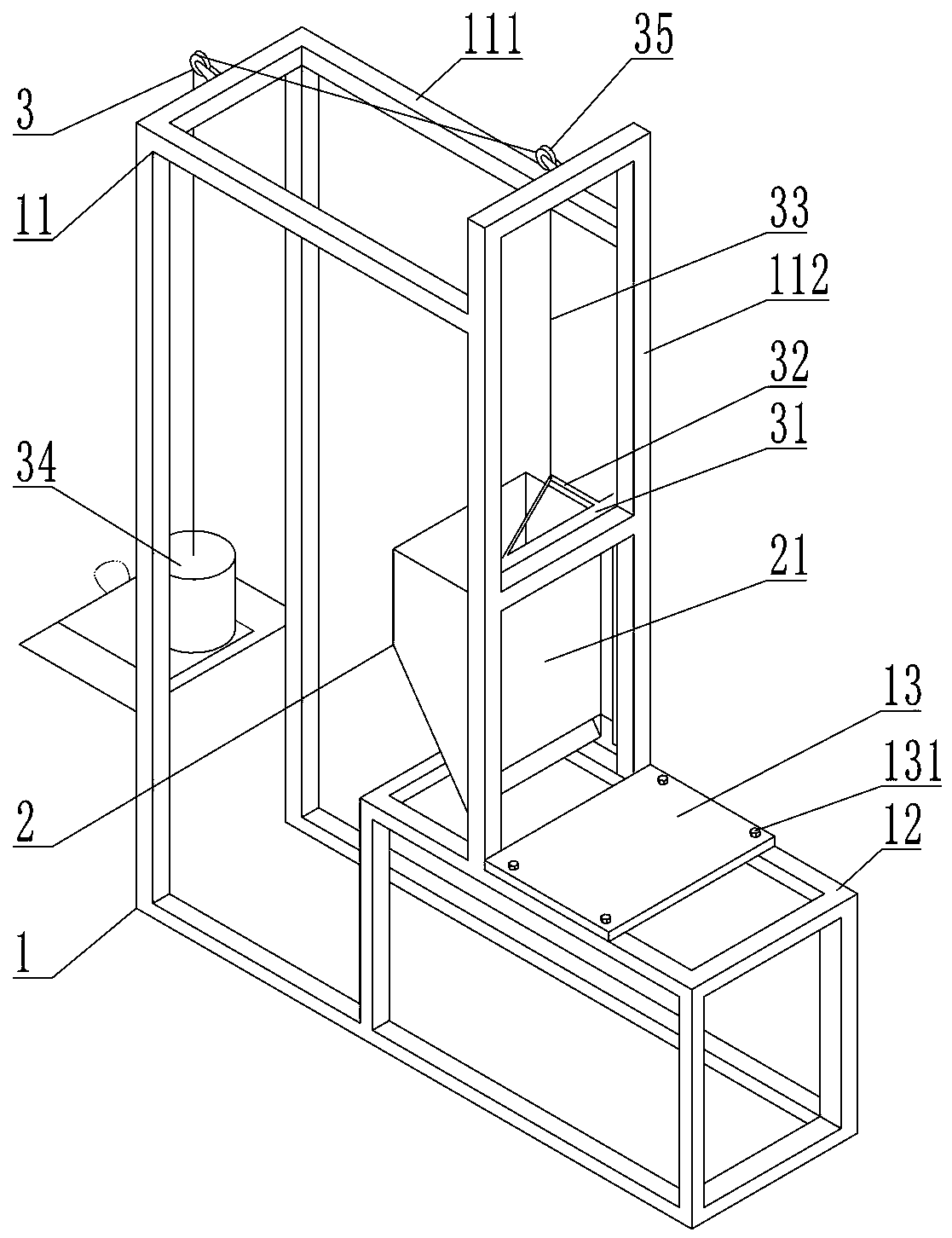

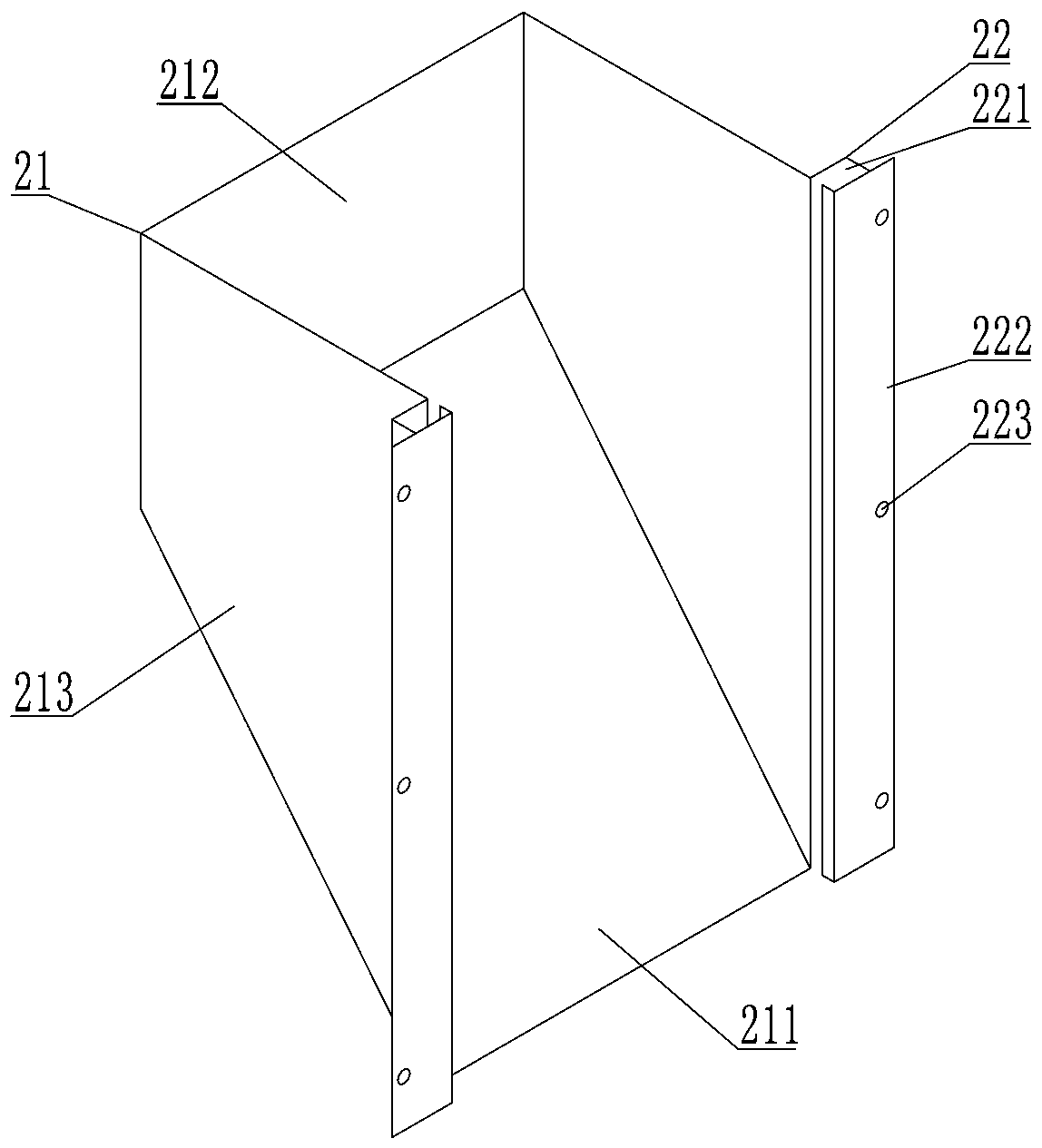

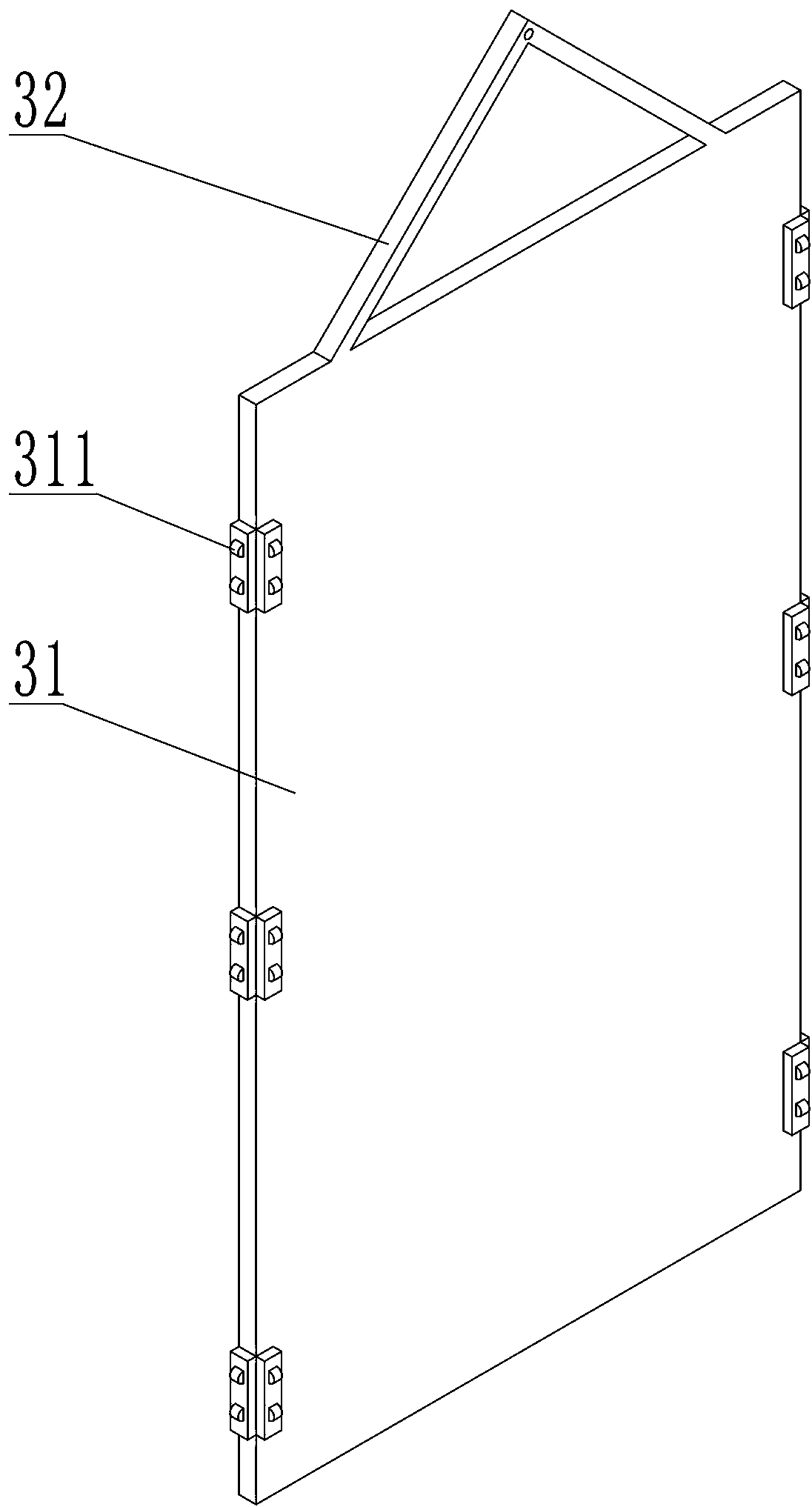

[0041] Such as Figure 1~Figure 4 Among them, a support structure impact load simulation test device, it includes a test bench 1, a loading container 2 and an impact mechanism 3; the test bench 1 includes a fixed frame 12 connected to the support frame 11, The fixed plate 13; the loading container 2 includes a slide rail 22 connected with the container body 21; the impact mechanism 3 includes a force transmission bar 32 connected with the baffle plate 31, a steel wire rope 33 connected with the force transmission bar 32, and The weight 34 connected with the wire rope 33, and the pulley 35 matched with the wire rope 33; the loading container 2 and the pulley 35 are connected and fixed with the support frame 11, the baffle plate 31 cooperates with the slide rail 22, and the weight 34 hangs on one side of the support frame 11 . The structure is simple, and the free-falling weight 34 pulls the steel wire rope 33 to slide on the pulley 35, and pulls the force transmission bar 32 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com