Combined membrane bioreactor

A membrane bioreactor, combined technology, is used in biological water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. The effect of increasing the contact area, increasing the impact force, and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] as attached figure 1 to attach Figure 6 Shown:

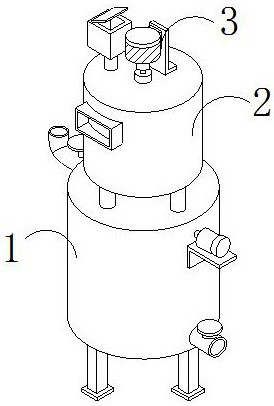

[0030] The invention provides a combined membrane bioreactor, the structure of which includes a collection cylinder 1, a reaction cylinder 2, and a motor 3, the bottom of the reaction cylinder 2 is fixed directly above the collection cylinder 1, and the motor 3 is vertically installed on the reaction cylinder 2 Top center position.

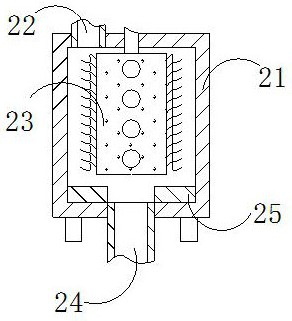

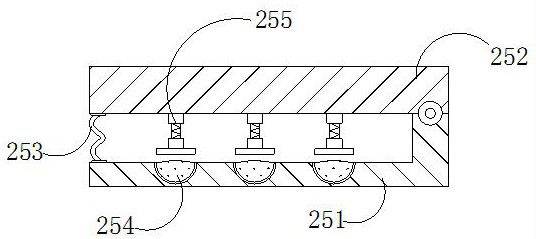

[0031] The reaction cylinder 2 includes a housing 21, a liquid inlet pipe 22, a membrane assembly 23, a connecting pipe 24, and an intercepting mechanism 25. The liquid inlet pipe 22 is vertically fixed on the top left side of the housing 21, and the membrane assembly 23 is set Inside the casing 21, the top end is movably matched with the motor 3, the top end of the connecting pipe 24 runs through the middle of the bottom surface of the casing 21, and the bottom end is connected to the top of the collection tube 1, and the intercepting mechanism 25 is located directly below the membrane as...

Embodiment 2

[0039] as attached Figure 7 To attach Figure 9 Shown:

[0040] Wherein, the clamping groove f24 includes a collar 24a, crushing teeth 24b, telescopic block 24c, and pushing block 24d, and the crushing teeth 24b are respectively embedded and connected with the upper and lower inner walls of the collar 24a, and the right end of the telescopic block 24c is fixed on the sleeve. The inner wall on the right side of the ring 24a, the right end of the pushing block 24d is installed on the left end of the telescopic block 24c, and the crushing teeth 24b are in the shape of a pointed triangle, which can increase the impact force of the crushing teeth 24b on the greasy substance, and is beneficial to the crushing teeth 24b and the crushing block. The active coordination of f23 can evenly crush the grease, reduce the volume of the grease, and further reduce the gravity of the grease, which is beneficial to the floating of the grease.

[0041] Wherein, the push block 24d includes a sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com