An impeller detection system and method for a range hood

A detection system and range hood technology, which is applied in measuring devices, measuring fluid pressure, and measuring fluid pressure through electromagnetic components, can solve problems such as inaccuracy, detection failure, and cumbersome adjustment of sampling current thresholds, and achieve real-time monitoring. Implementation, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

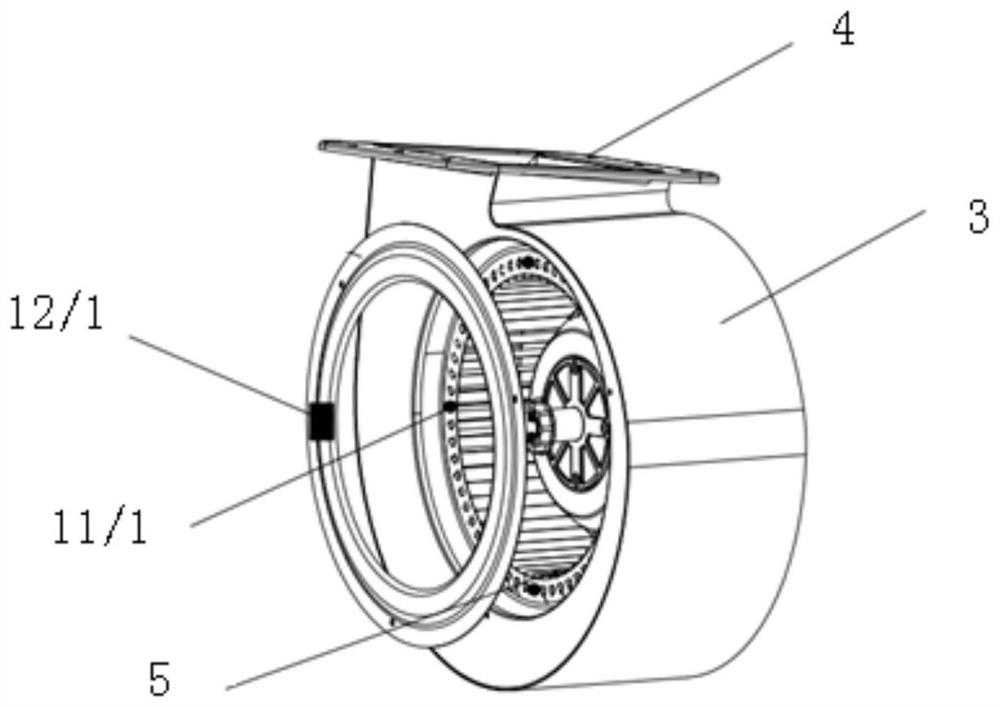

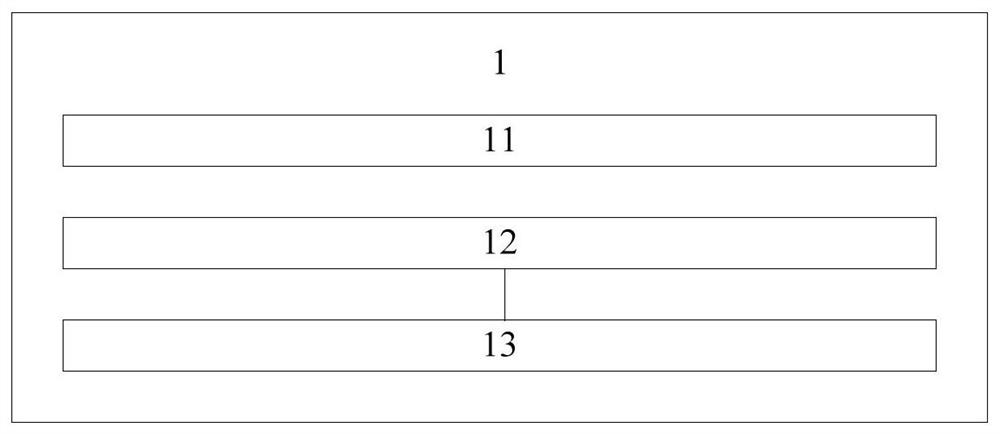

[0059] A kind of impeller detection system 1 of range hood, such as figure 1 , figure 2 As shown, the range hood may include: a motor (not shown), a volute 3 and an air duct 4, the volute 3 communicates with the air duct 4; the volute 3 is provided with an impeller 5, and the motor is used to drive the impeller 5 to rotate; the impeller The detection system 1 may include: a magnetic element 11 disposed on the impeller 5, a magnetic field detection module 12 disposed on the volute 3, and a smoke machine main control unit 13;

[0060] The magnetic field detection module 12 can be used to detect the magnetic field generated by the magnetic element 11 during the rotation of the impeller 5, and form a corresponding pulse signal according to the detected magnetic field signal;

[0061] The main control unit 13 of the hood is used to detect whether the impeller 5 has an abnormal eccentricity according to the amplitude change of the pulse signal, and detect whether there is an abnor...

Embodiment 2

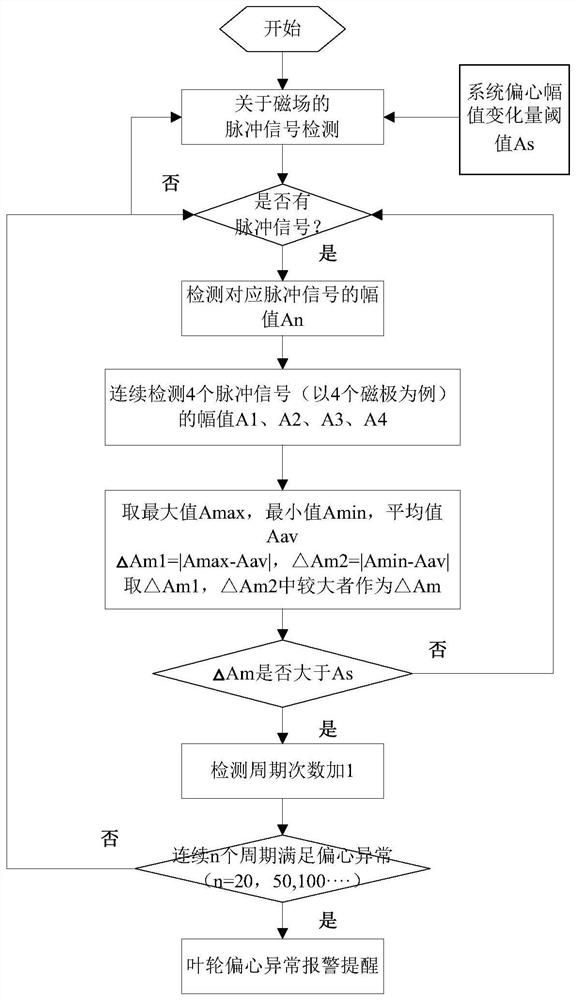

[0069] like image 3 As shown, this embodiment provides a specific judgment scheme for abnormal impeller eccentricity on the basis of the first embodiment.

[0070] Optionally, the main control unit 13 of the range hood detects whether the impeller 5 has an abnormal eccentricity according to the amplitude change of the pulse signal may include:

[0071] Comparing the amplitude variation of the pulse signal with a preset amplitude variation threshold;

[0072] When the amplitude variation of the pulse signal is greater than or equal to the amplitude variation threshold, it is determined that the impeller is eccentrically abnormal; when the amplitude variation of the pulse signal is smaller than the amplitude variation threshold, it is determined that the impeller is normal.

[0073] In the embodiment of the present invention, under normal circumstances, there may be a small amount of eccentricity during the operation of the impeller 5, but generally it will be kept within the ...

Embodiment 3

[0084] like image 3 As shown, on the basis of the second embodiment, this embodiment further defines the method for obtaining the amplitude variation of the magnetic element 11 including a plurality of time pulse signals.

[0085] Optionally, the magnetic element 11 may include one or more;

[0086] When there are multiple magnetic elements 11, the main control unit 13 of the range hood can also be used to obtain the amplitude variation of the pulse signal through the following scheme:

[0087] calculating the average value of the amplitudes of pulse signals corresponding to multiple magnetic elements detected within a preset detection period;

[0088] calculating respectively the absolute value of the maximum value and the difference between the minimum value and the average value among the amplitudes of the pulse signals corresponding to the plurality of magnetic elements;

[0089] The greater value of the two calculated absolute values is taken as the amplitude variation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com