Preparation process of cold-proof fabric

A production process and fabric technology, which can be used in the processing of textile materials, fabric surface trimming, and equipment configuration for processing textile materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

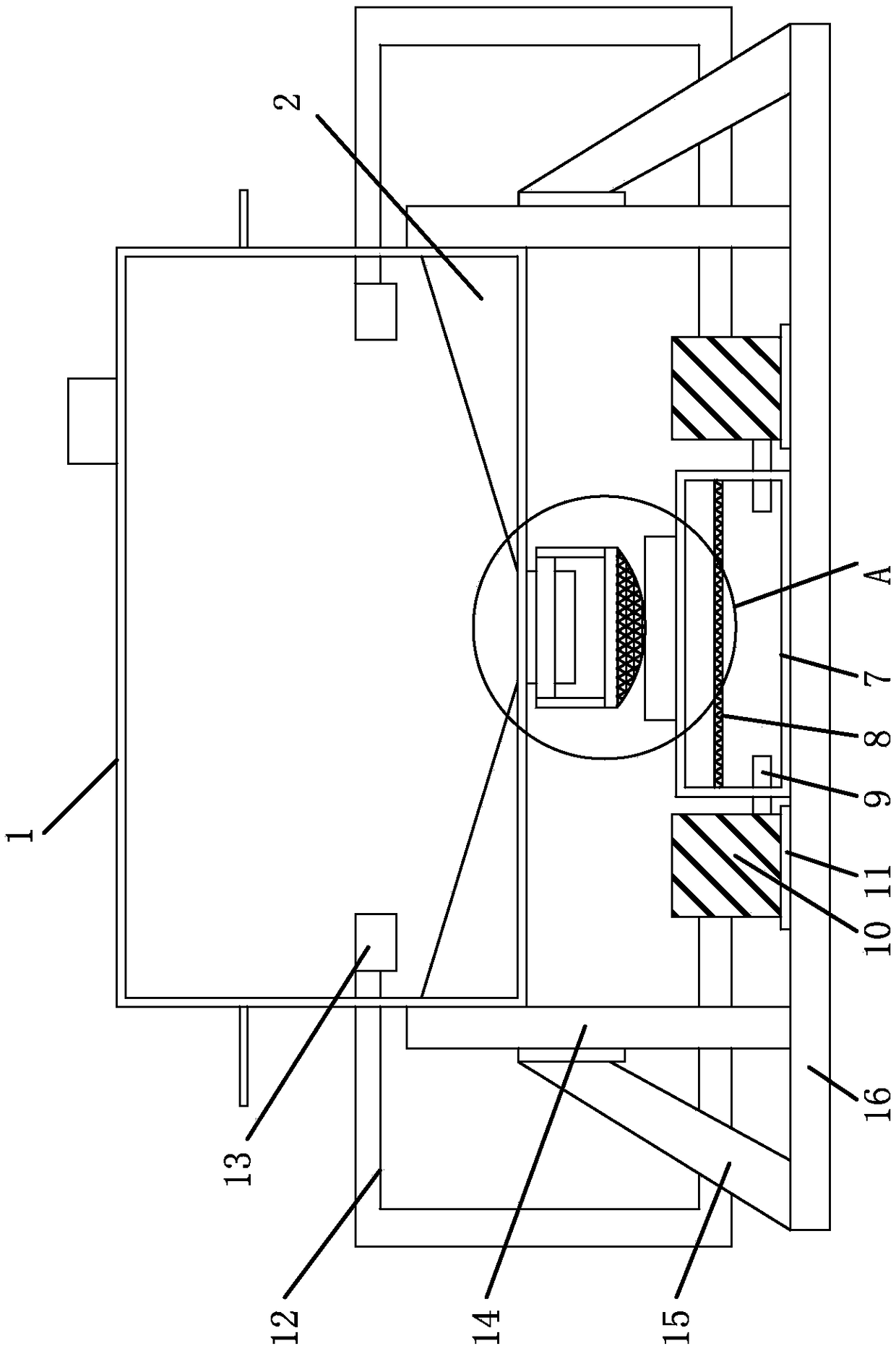

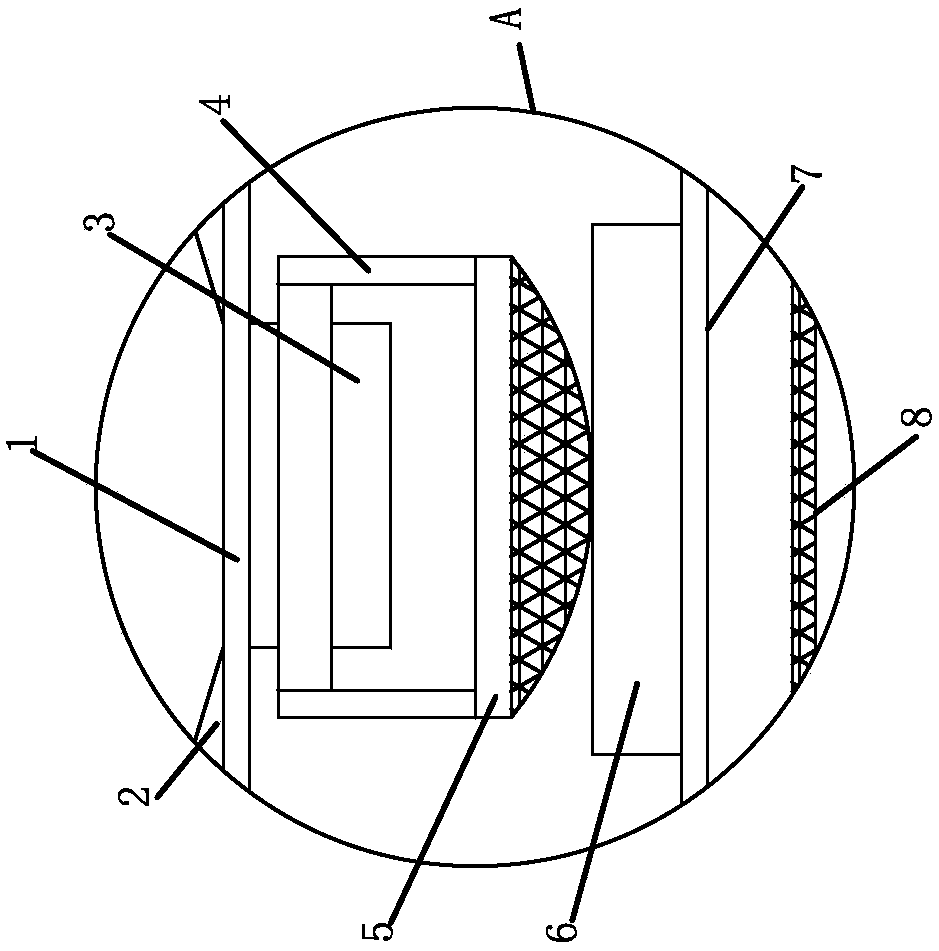

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

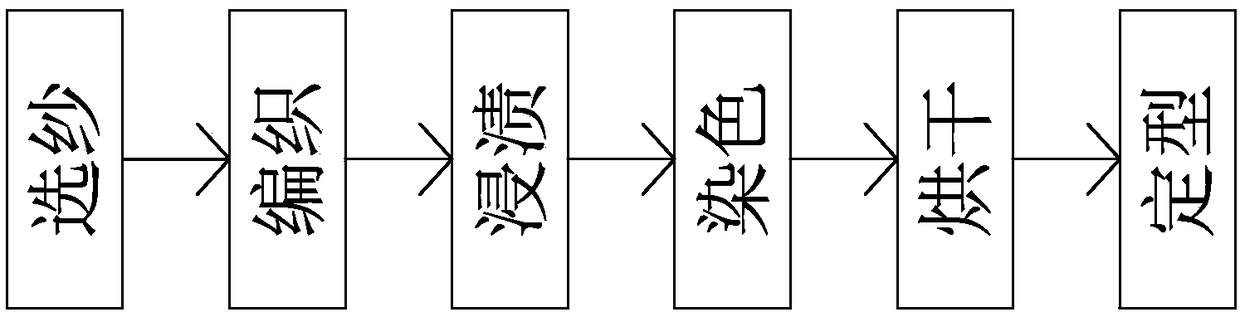

[0028] Such as figure 1 Shown, a kind of manufacture craft of cold-proof fabric, this manufacture craft comprises the following steps:

[0029] a. Yarn selection: use wool as warp and polyester as weft;

[0030] b. Weaving: knitting the warp and weft into the base fabric through the knitting machine;

[0031] c. Impregnation: Put the base cloth into the impregnation device for impregnation. The percentage content in the impregnation device: penetrant 1-2%, ammonium sulfate 5-7%, dispersant 2-3%, water 70-80%, whitening agent Fabric 1-2%, oily cleaner 5-6%;

[0032] d, dyeing: heating the wool reactive dye in the dyeing vat, putting the fabric in step c into the dyeing vat;

[0033] e. Drying: place the dyed fabric in a texti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com