Refining agent for high-temperature alloy used in the case of relatively high superheat and its preparation and application

A high-temperature alloy and refiner technology, which is applied in the field of superalloy refiner and its preparation, can solve the problems of not having a refinement effect, and achieve the effects of low manufacturing cost, simple addition method and high economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

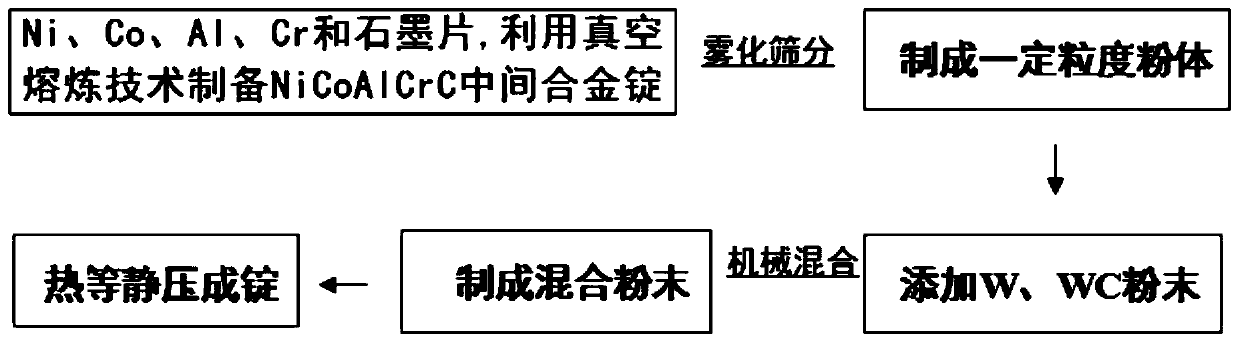

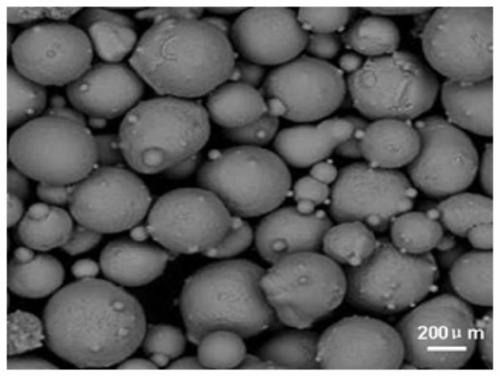

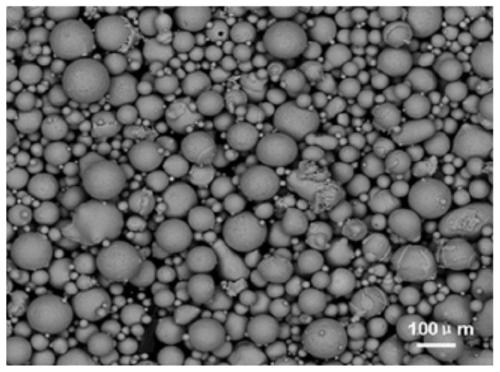

[0035] In this example, the refining agent is prepared according to the method described in the technical solution of the present invention, and the process is as follows figure 1 Shown, and applied to the preparation of K418B alloy test rod. Firstly, the NiCoAlCrC master alloy ingot is prepared by vacuum smelting technology, and then the NiCoAlCrC master alloy powder is prepared by atomization treatment method, and after sieving and classification, the master alloy powder with a particle size in the range of 30-60 mesh is obtained, such as figure 2 shown. The composition content of the NiCoAlCrC master alloy powder is: Co 23%, Al 5%, Cr 8%, C 0.15%, and Ni. Then mix with W powder and WC powder with a particle size of 300-500 mesh, the weight ratio is: NiCoAlCrC master alloy powder 50%, W powder 30%, WC powder 20%, see image 3 . Hot isostatic pressing into ingots at a temperature of 200°C and a time of 12 hours, see Figure 4 . Finally, it is added in the form of a cyli...

Embodiment 2

[0037] In this embodiment, the refining agent is prepared according to the method described in the technical solution of the present invention, and applied to the casting of K418B alloy. Firstly, the NiCoAlCrC master alloy ingot is prepared by vacuum smelting technology, and then the NiCoAlCrC master alloy powder is prepared by the atomization method, and the master alloy powder with a particle size in the range of 30-60 mesh is obtained after sieving and classification. The composition content of the NiCoAlCrC master alloy powder is: Co 20%, Al 6%, Cr 9%, C 0.12%, and Ni. Then it is mixed with W powder and WC powder with a particle size of 500-800 mesh, and the weight ratio is 65% of NiCoAlCrC master alloy powder, 20% of W powder and 15% of WC powder. Hot isostatic pressing into ingots under the conditions of temperature 300°C and time 6h. Finally, it is added in the form of a cylindrical ingot during the pouring process of the K418B alloy casting, and the outside is wrapped...

Embodiment 3

[0039]In this embodiment, the refining agent is prepared according to the method described in the technical solution of the present invention, and applied to the casting of K418B alloy. Firstly, the NiCoAlCrC master alloy ingot is prepared by vacuum smelting technology, and then the NiCoAlCrC master alloy powder is prepared by the atomization method, and the master alloy powder with a particle size in the range of 30-60 mesh is obtained after sieving and classification. The composition content of the NiCoAlCrC master alloy powder is: Co 25%, Al 4%, Cr 10%, C 0.17%, and Ni. Then it is mixed with W powder and WC powder with a particle size of 800-1000 mesh, and the weight ratio is 55% of NiCoAlCrC master alloy powder, 20% of W powder and 25% of WC powder. Hot isostatic pressing into ingots under the conditions of temperature 350°C and time 3h. Finally, it is added in the form of a cylindrical ingot during the pouring process of the K418B alloy casting, and is wrapped with nicke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com