Modified beta molecular sieve as well as preparation method and application thereof

A β molecular sieve and modification technology, which is applied in the direction of molecular sieves and base exchange compounds, molecular sieve catalysts, carboxylate preparation, etc., can solve the problems of easy loss of active components, loss of sulfonic acid groups, and high temperature resistance of resin catalysts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

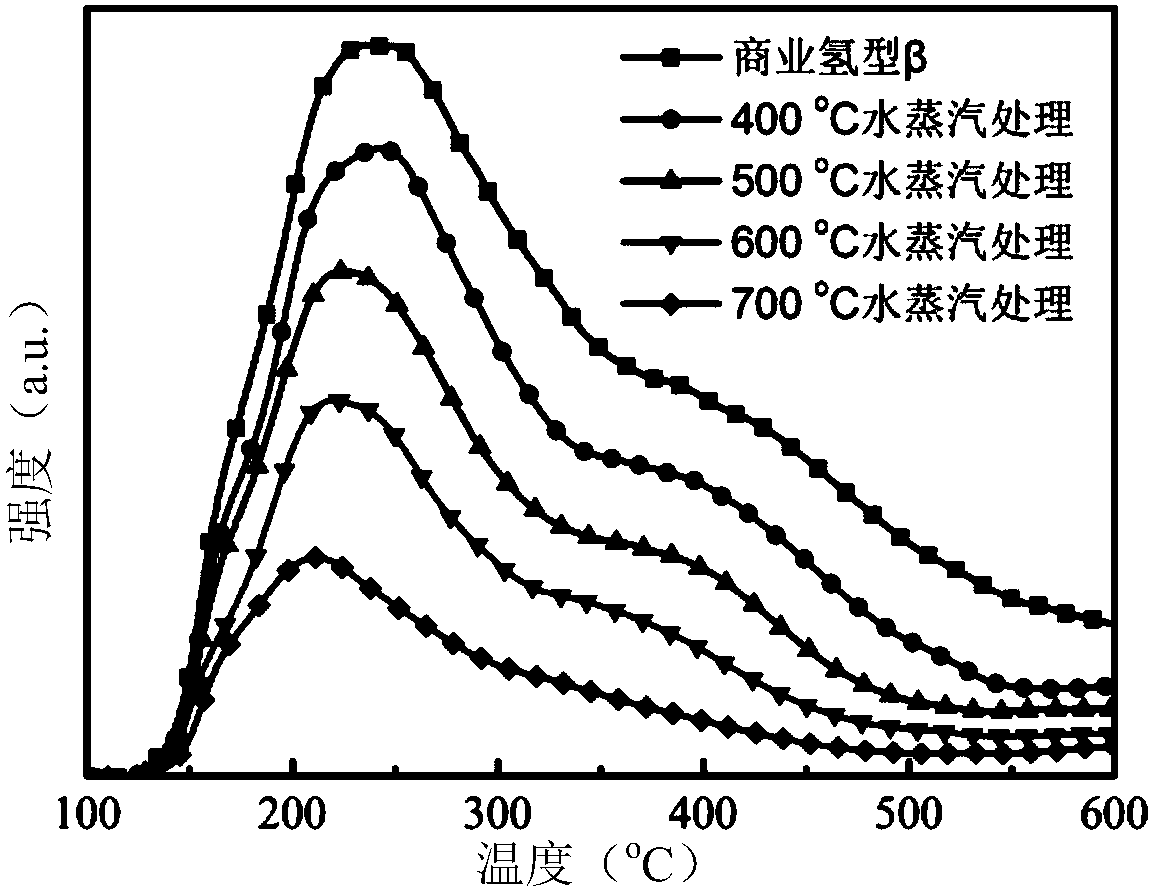

[0045] Put 30g of 20-40 mesh commercial hydrogen-type β-molecular sieves in a quartz cup and put them in the constant temperature section of the hydrothermal aging device. 0.5h; heat up to 480°C at 30°C / min, and keep the temperature constant for 0.5h for every 30°C rise; heat up to 500°C at 25°C / min, keep the temperature for 3h. After processing, naturally cool to room temperature and set aside.

[0046] Using 5g of the modified β molecular sieve prepared above as a catalyst, the esterification reaction of acetic acid and butene was evaluated. The reaction temperature was 110°C, the reaction pressure was 2MPa, and the weight hourly space velocity was 2.0h -1 , the molar ratio of acetic acid and butene is 1.5. The results show that the conversion rate of butene is 40.8%, and the selectivity of sec-butyl acetate is 100%.

Embodiment 2

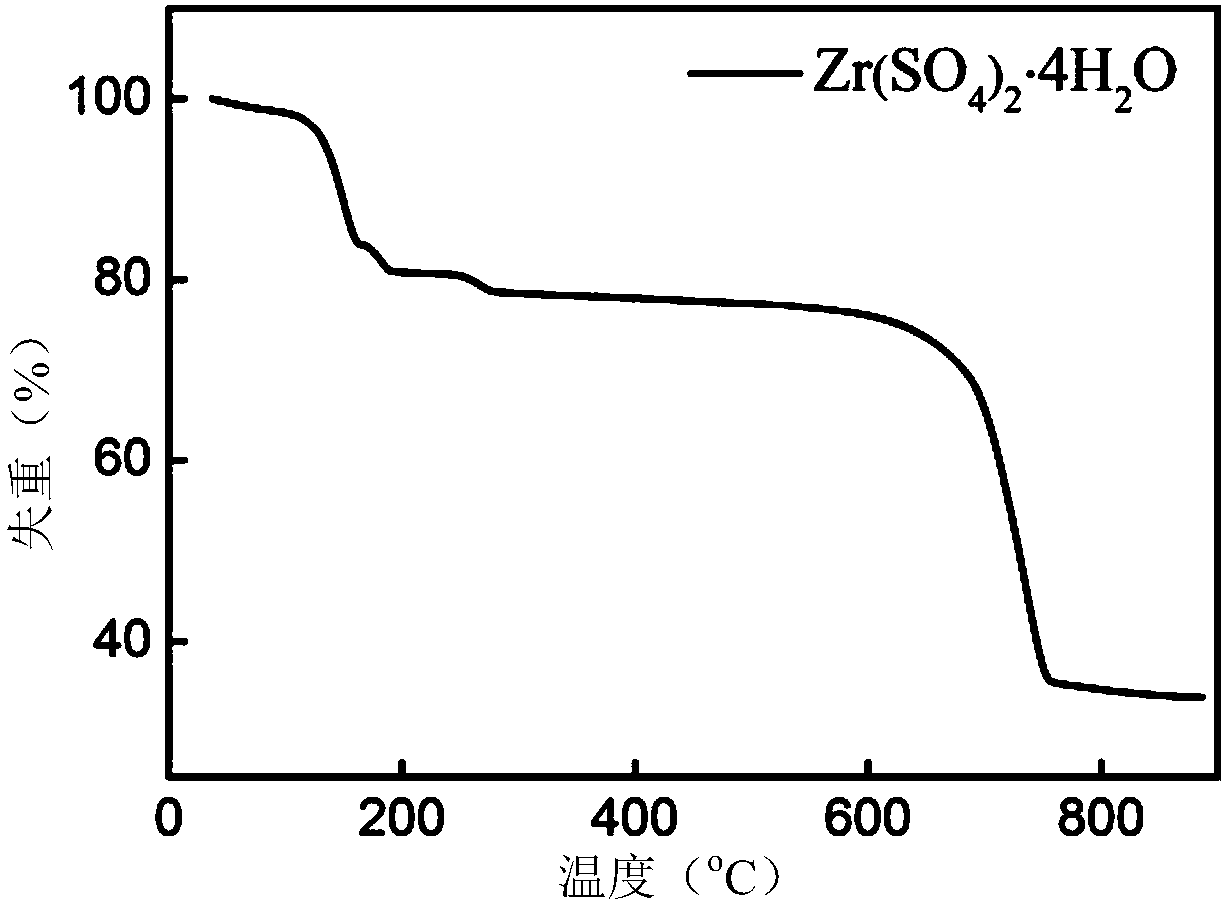

[0048] Put 30g of 20-40 mesh commercial hydrogen-type β-molecular sieves in a quartz cup and put them in the constant temperature section of the hydrothermal aging device. 0.5h; heat up to 560°C at 30°C / min, and keep the temperature constant for 0.5h for every 40°C rise; heat up to 600°C at 25°C / min, keep the temperature constant for 5h. Then, adopt equal volume impregnation method to load 10% zirconium sulfate thereon (thermogravimetric curve such as figure 2 shown), dried, baked at 200°C for 3h, cooled naturally to room temperature, and set aside.

[0049] Using 5g of the modified β molecular sieve prepared above as a catalyst, the esterification reaction of acetic acid and butene was evaluated. The reaction temperature was 130°C, the reaction pressure was 2MPa, and the weight hourly space velocity was 1.0h -1 , the molar ratio of acetic acid and butene is 1.5. The results show that the conversion rate of butene is 46.8%, and the selectivity of sec-butyl acetate is 100%. ...

Embodiment 3

[0051] Put 30g of 20-40 mesh commercial hydrogen-type β-molecular sieves into a quartz cup and place them in the constant temperature section of the hydrothermal aging device. 1h; the temperature was raised to 550°C at 35°C / min, and the temperature was kept constant for 1h for every 30°C rise; the temperature was raised to 600°C at 30°C / min, and the temperature was kept constant for 5h. Then, 20% zirconium sulfate was loaded on it by an equal volume impregnation method, dried, calcined at 200° C. for 3 hours, cooled naturally to room temperature, and set aside.

[0052] Using 5g of the modified β molecular sieve prepared above as a catalyst, the esterification reaction of acetic acid and butene was evaluated. The reaction temperature was 120°C, the reaction pressure was 3MPa, and the weight hourly space velocity was 2.0h -1 , the molar ratio of acetic acid and butene is 2.0. The results show that the conversion rate of butene is 59.0%, and the selectivity of sec-butyl acetate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com