Tightness detection platform for machine parts

A technology for detecting platforms and mechanical parts, applied in the field of measuring tools, can solve problems such as movement, detection platform collision, bolt or screw loosening, etc., to prevent equipment damage, reduce thread clearance, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

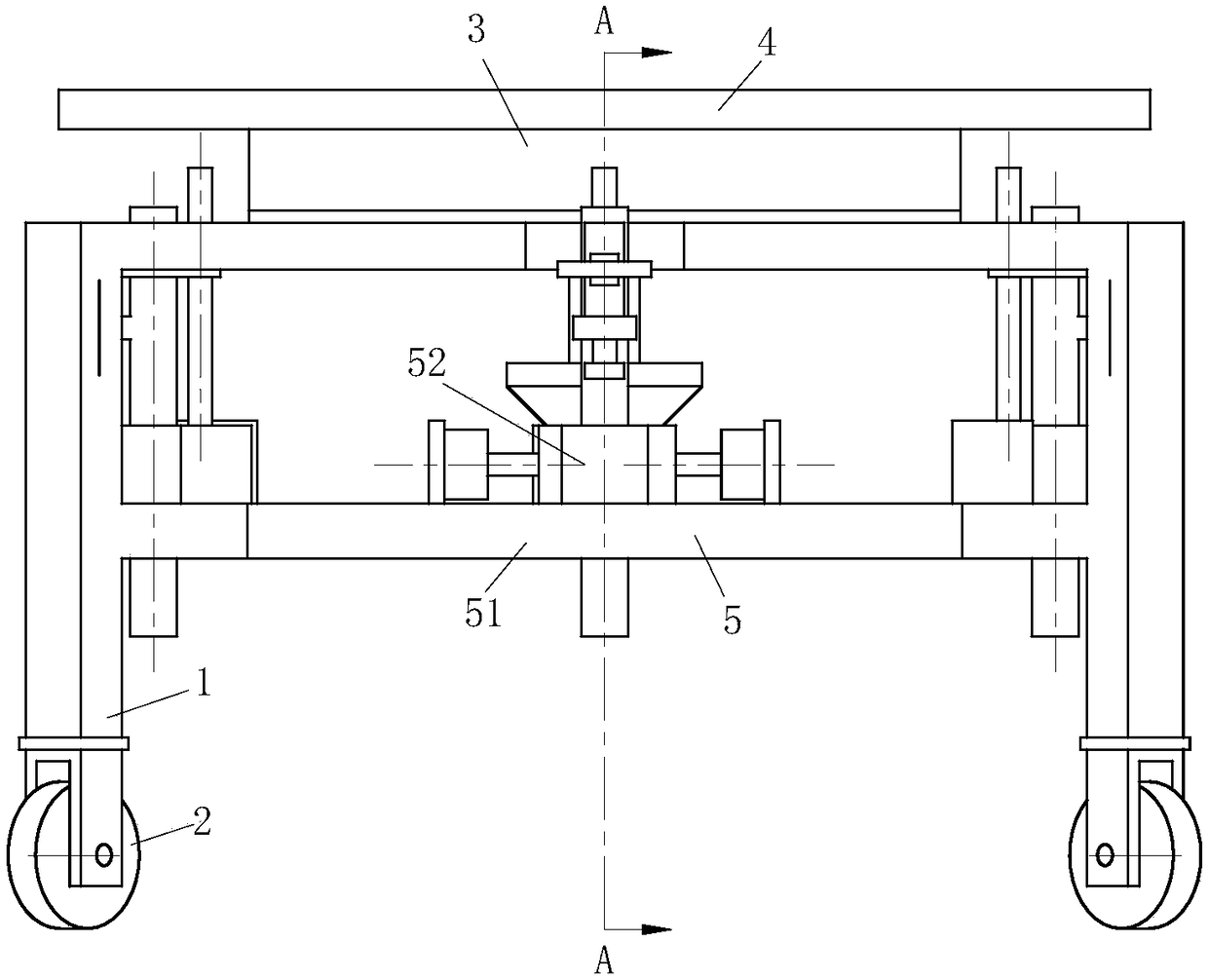

Image

Examples

Embodiment approach

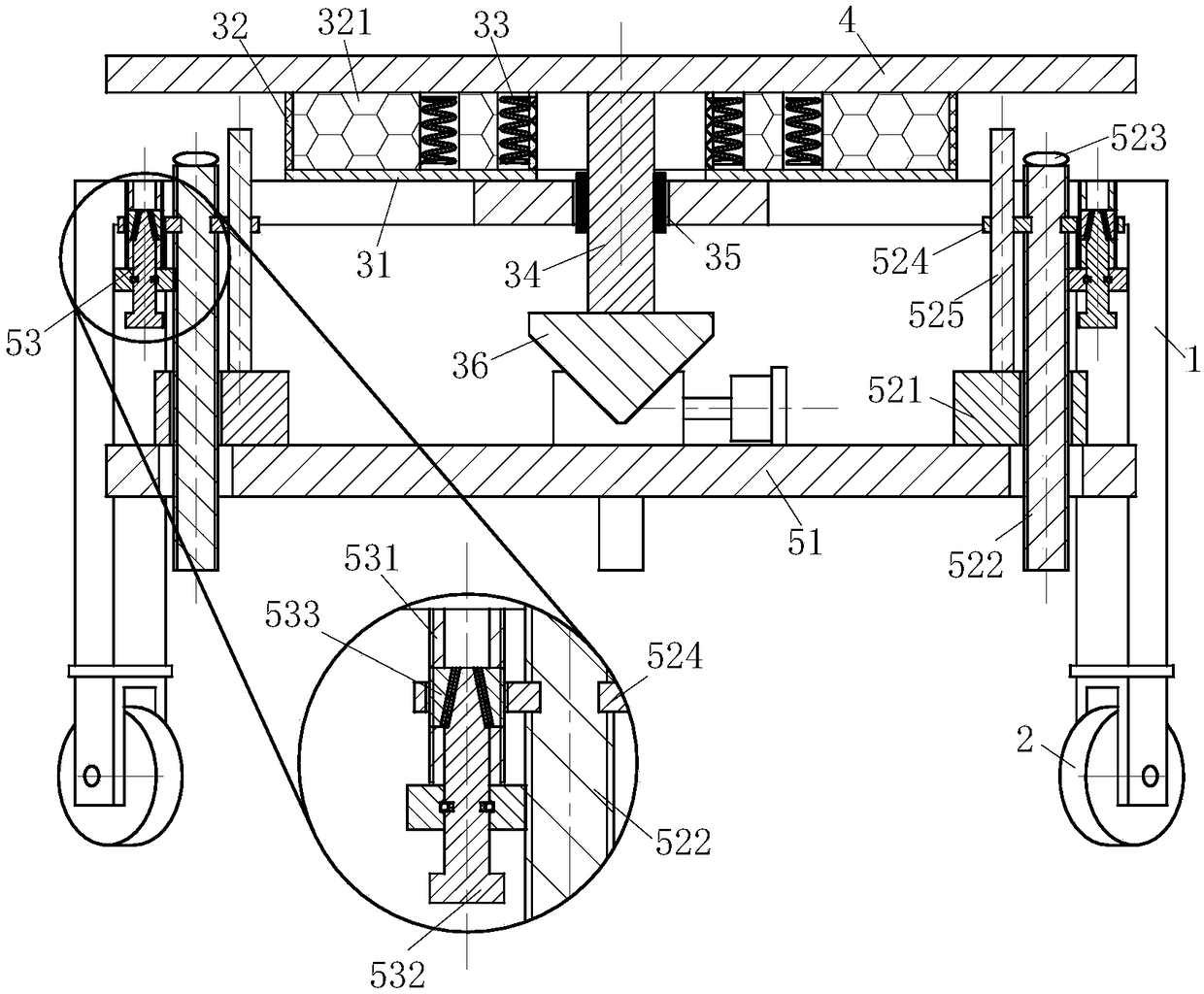

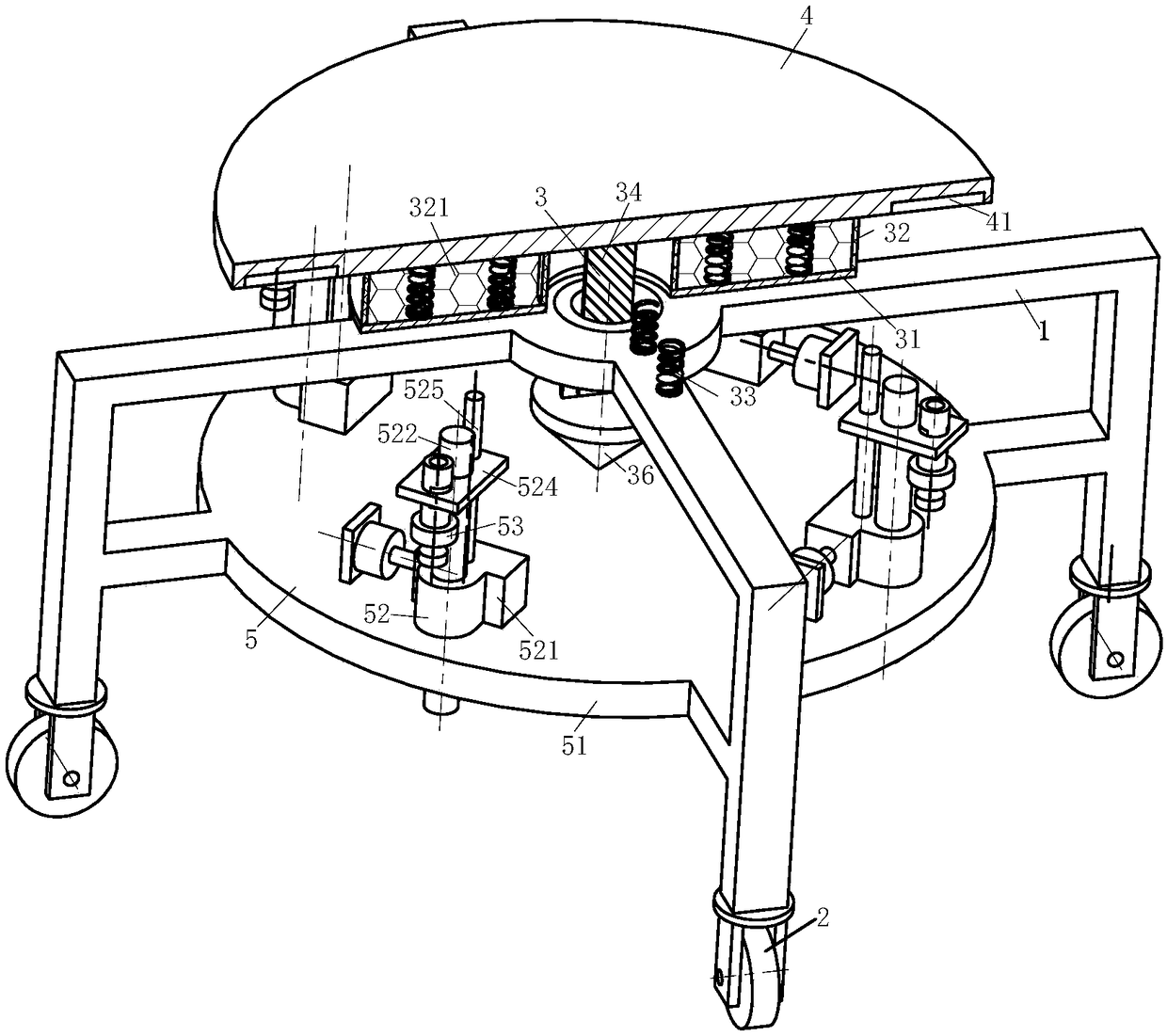

[0035] As an embodiment of the present invention, the inside of the elastic airbag 32 is provided with a set of supporting airbags 321, and the supporting airbags 321 form a mesh inside the elastic airbag 32. During the automatic balancing process of the measuring table 4, the supporting airbags 321 will measure The steering force of the platform 4 is evenly distributed; and the movement of the measuring platform 4 is slowed down so that the measuring platform 4 can be adjusted smoothly to prevent damage to the equipment caused by violent turbulence.

[0036] As an embodiment of the present invention, the lower surface of the measuring table 4 is provided with an annular weight-reducing groove 41, and the weight-reducing groove 41 is evenly arranged around the center of the circle of the measuring table 4, so that the center of gravity of the measuring table 4 is closer to the center of the circle. Position, improve the accuracy of automatic balance.

[0037] As an embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com