Adjusting device for a cutting tool and cutting tool having an adjusting device

A technology of cutting tools and cutting tools, which is applied in the direction of tool holders, manufacturing tools, mechanical equipment, etc., can solve the problems of endangering the accuracy of cutting tools or the stability of diameter and size, and achieve the effect of high diameter and size stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

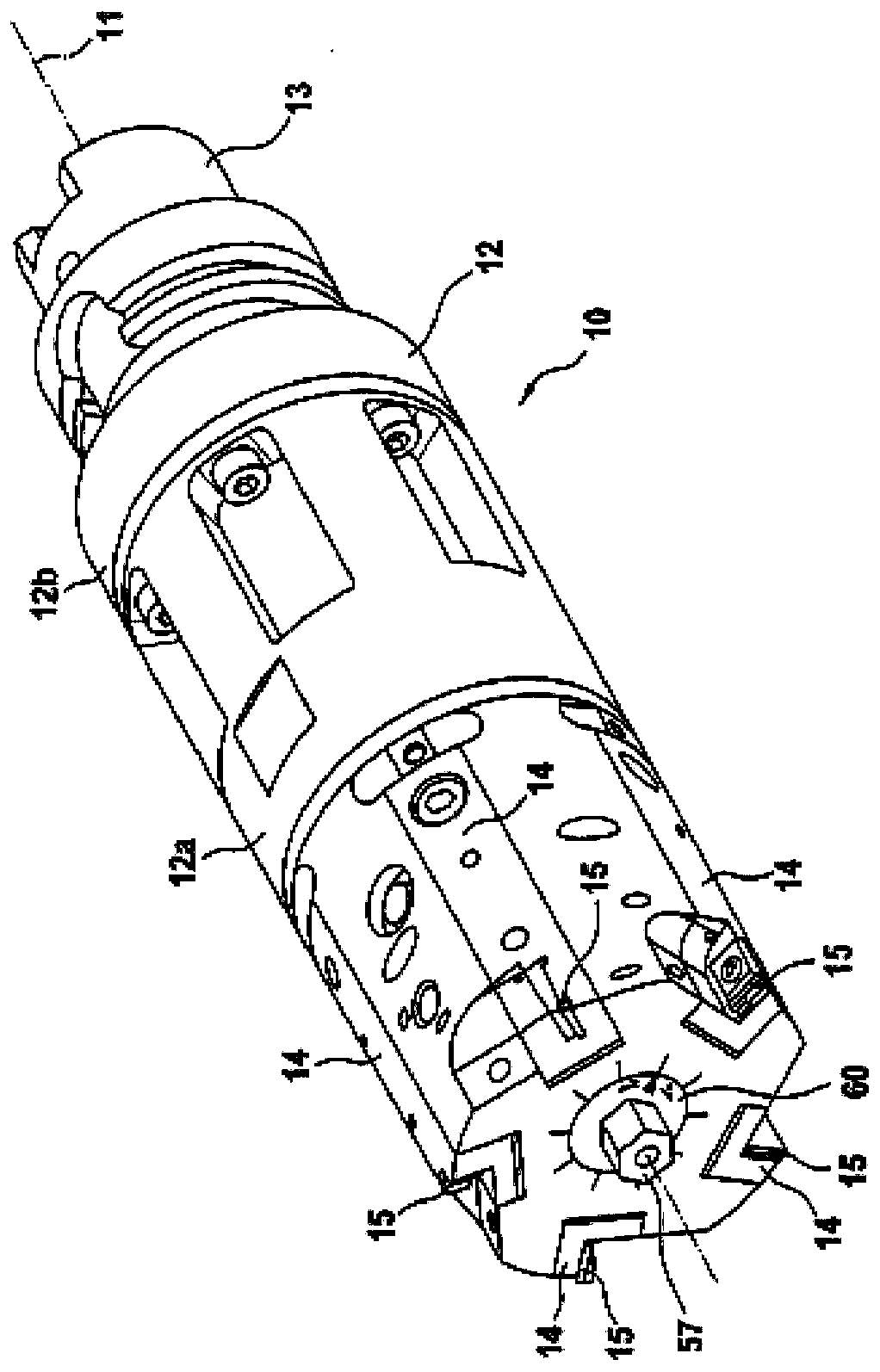

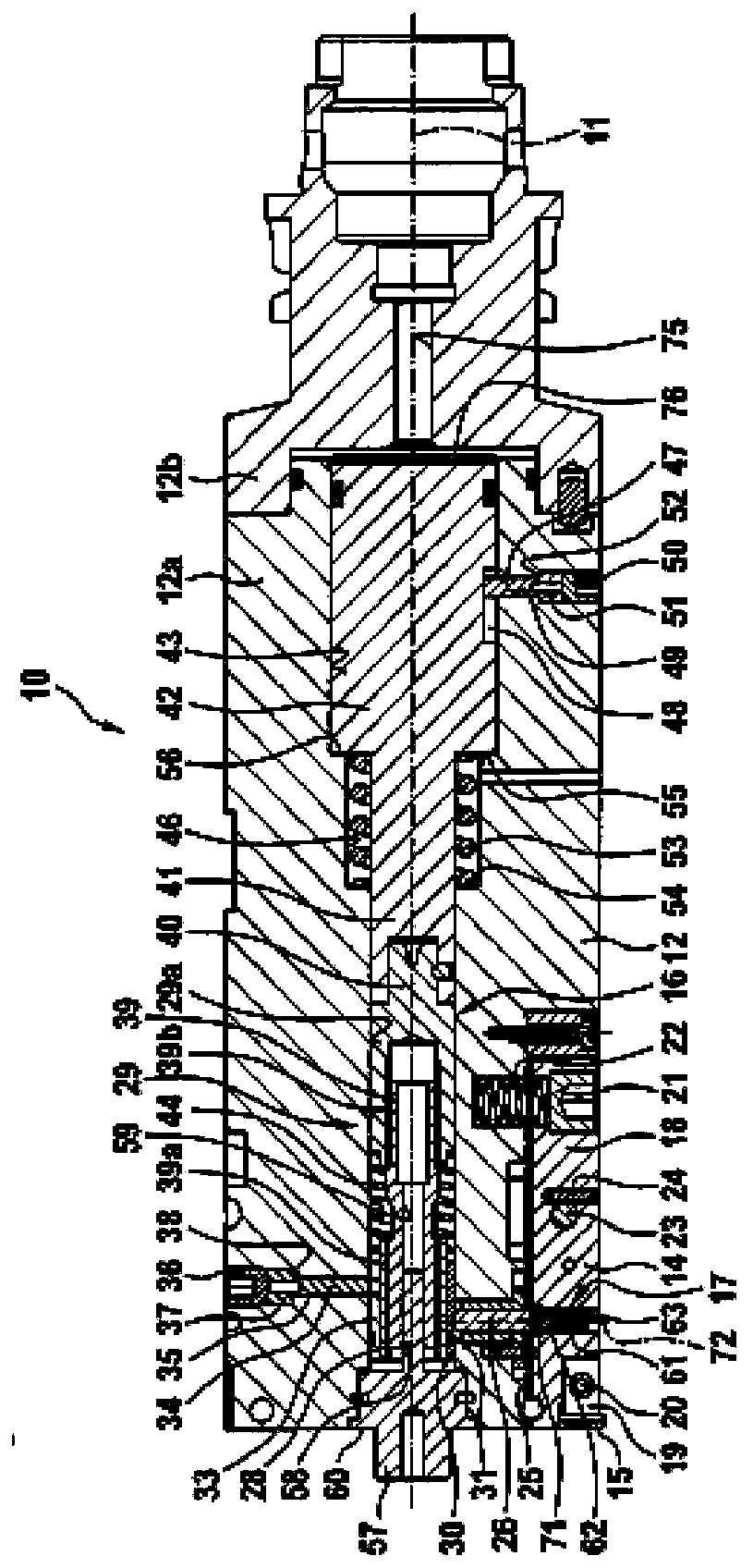

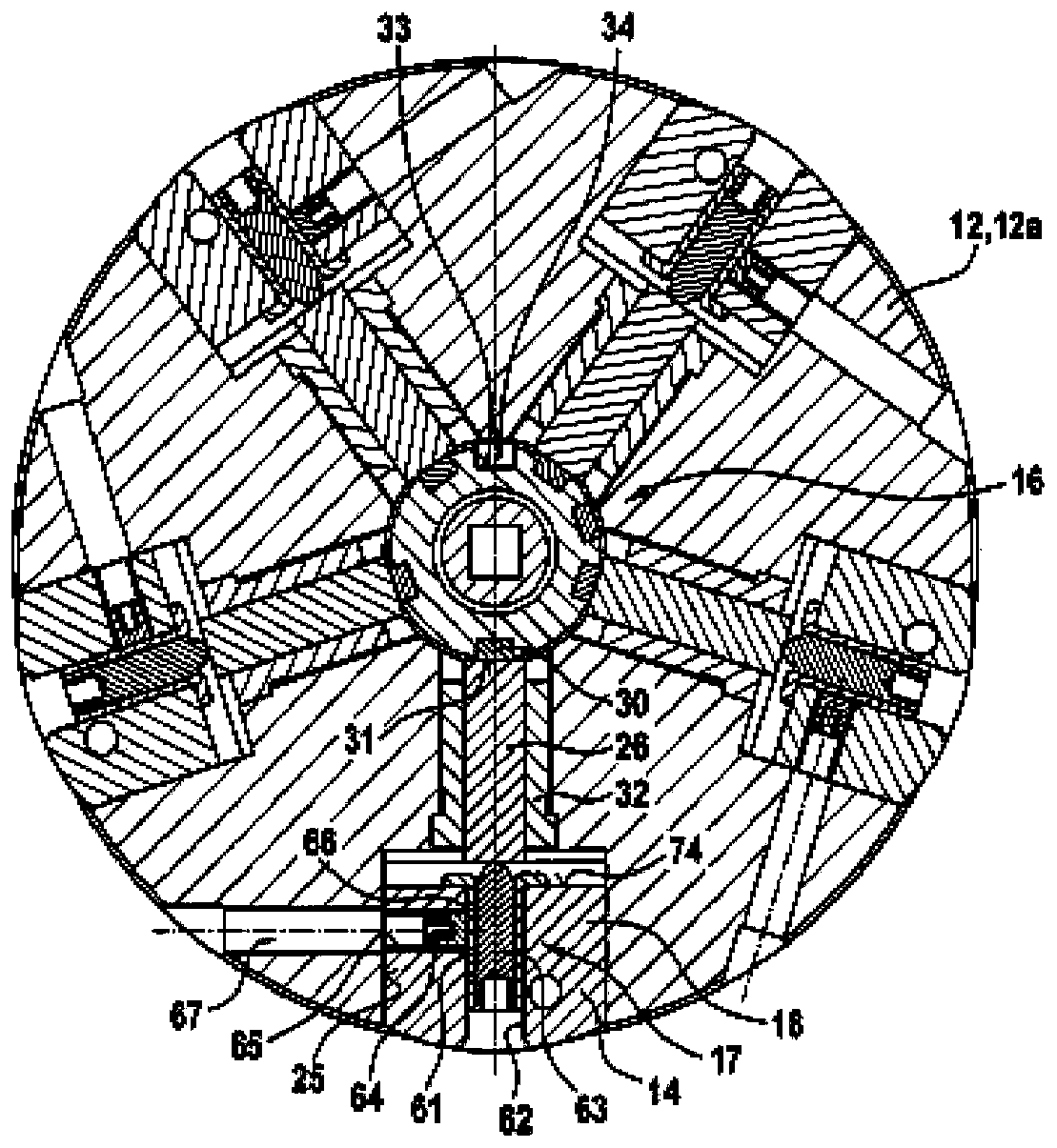

[0031] figure 1 A perspective side view of a multi-edged cutting tool 10 , for example for machining cylinder bores of internal combustion engines, is shown. Thus, the cutting tool 10 may be referred to as a cylinder bore machining tool or generally as a drilling remachining tool or a drilling finishing tool.

[0032] The cutting tool 10 has a base body 12 extending along a longitudinal center axis or axis of rotation 11 , which in the embodiment shown is modularly formed from a front part and a rear part. like figure 1 As shown, the front portion 12a and the rear portion 12b are screwed to each other. The cutting tool 10 is at its rear end ( figure 1 There is a coupling shank 13 to be connected to eg a machine tool spindle, which in the embodiment shown is formed by a HSK (Hollow Shaft Taper) shank. Alternatively, however, it is also possible, for example, to provide a so-called SK (steep taper) shank or the like. The cutting tool 10 can be used stationary or driven in r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com