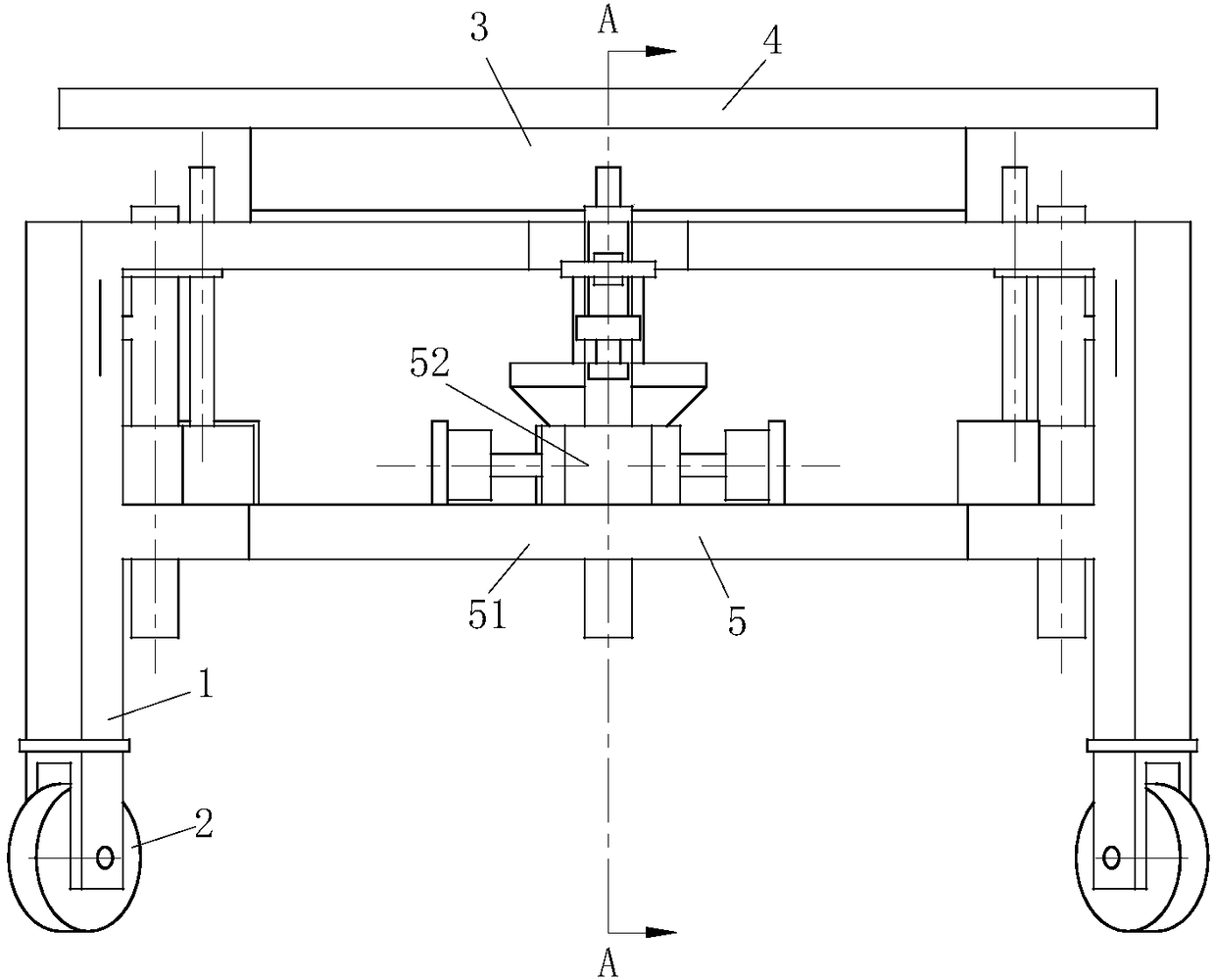

Detection system capable of realizing automatic leveling of machine part

A technology of mechanical parts and automatic leveling, which is applied in the field of measuring tools, can solve the problems that the detection platform cannot be moved frequently, affects the production efficiency of enterprises, and the number of detection platforms is limited, so as to achieve the effect of increasing resistance, slowing down movement and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

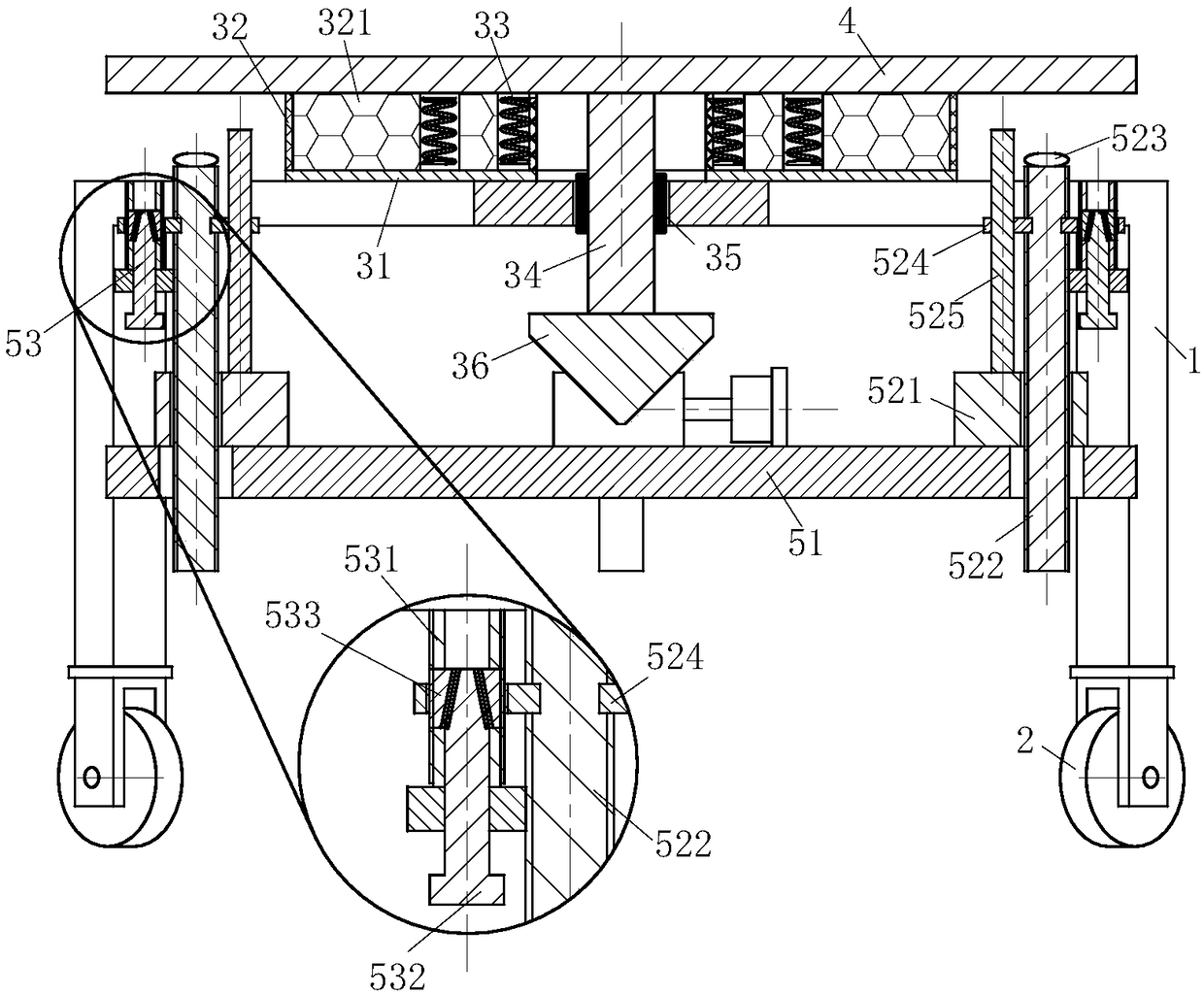

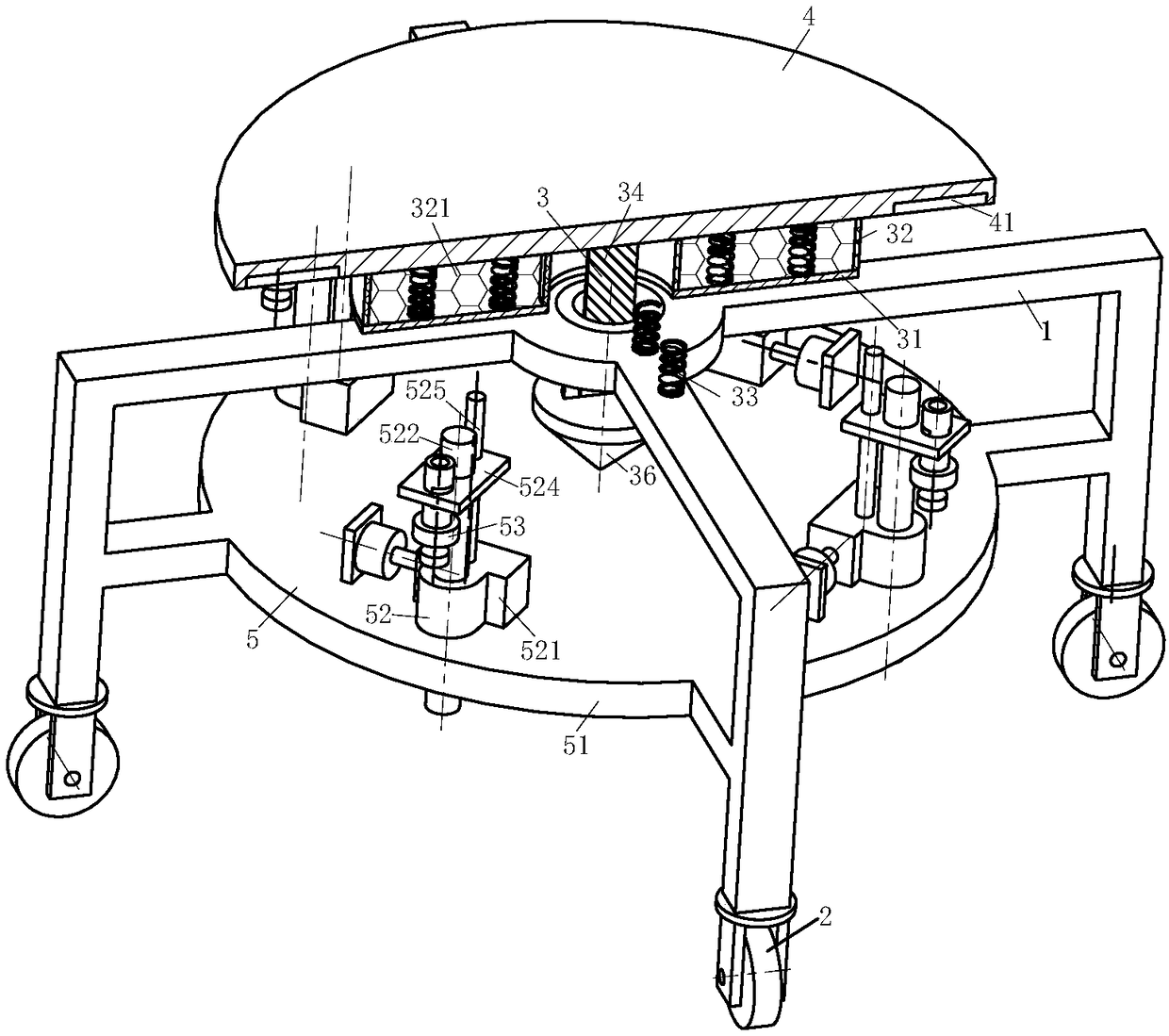

[0032]As an embodiment of the present invention, the support unit 52 includes a screw lifter 521, a detection screw 522, a detection air bag 523, a pressure sensor, a fixed plate 524, a guide column 525 and a fastening bolt 53; the screw lifter 521 Installed on the upper surface of the mounting plate 51, the screw lifter 521 is connected with the detection screw 522; the rotation of the screw lifter 521 can drive the detection screw 522 to approach or move away from the measuring table 4; one end of the detection screw 522 is provided with a detection airbag 523, the inside of the detection air bag 523 is provided with a pressure sensor; the fixed plate 524 is rotated and installed on the upper part of the detection screw 522; , the other end of the fixing plate 524 is screwed with the fastening bolt 53, the fastening bolt 53 is used to fix the measuring platform 4, the rotation of the screw lifter 521 can drive the detection screw 522 to approach the measuring platform 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com