Manufacturing method for high-precision single-curved surface aluminum alloy skin

A manufacturing method and single-curved surface technology, applied in the field of precision machining, can solve problems such as inaccurate control of skin boundary dimensions, reflection skin overlapping, and insufficient stretching range, so as to achieve the goal of reducing Potential safety hazards and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make it easier for those skilled in the art to understand the technical solution of this patent, and at the same time, in order to make the technical purpose, technical solution and beneficial effect of this patent clearer, and to fully support the protection scope of the claims, the following is a specific case in the form of this patent. The technical solution of the patent makes further and more detailed descriptions.

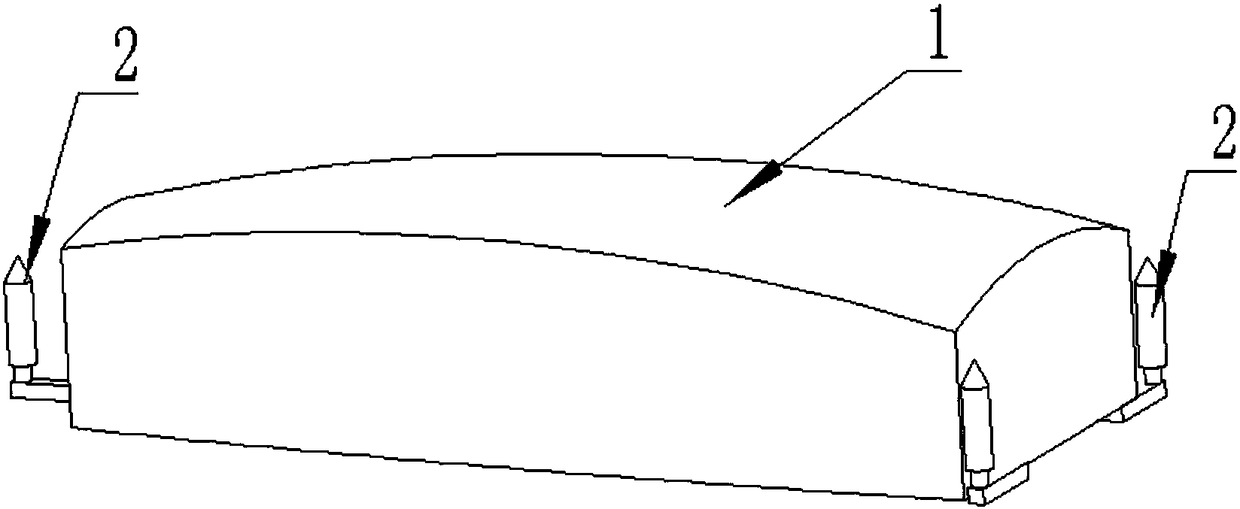

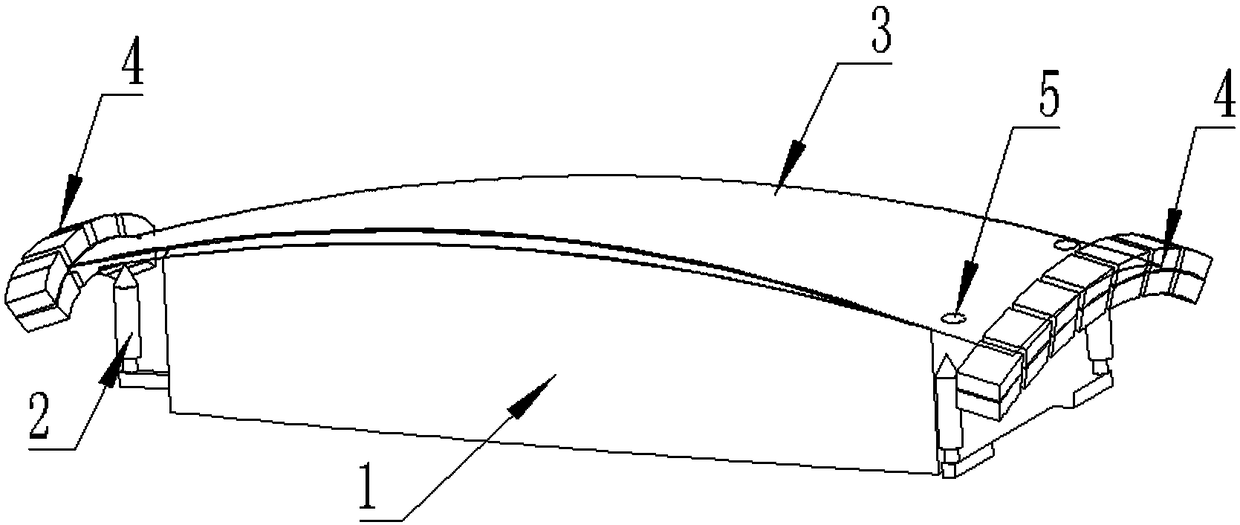

[0035] A method for manufacturing a high-precision single-curved aluminum alloy skin, comprising the following steps:

[0036] (1) To prepare the aluminum alloy sheet, the length and width of the sheet are required to exceed the maximum width and maximum length of the target skin and have a certain margin;

[0037] (2) Perform quenching heat treatment on the prepared aluminum alloy plate, thereby reducing the strength of the material and increasing the ductility of the material;

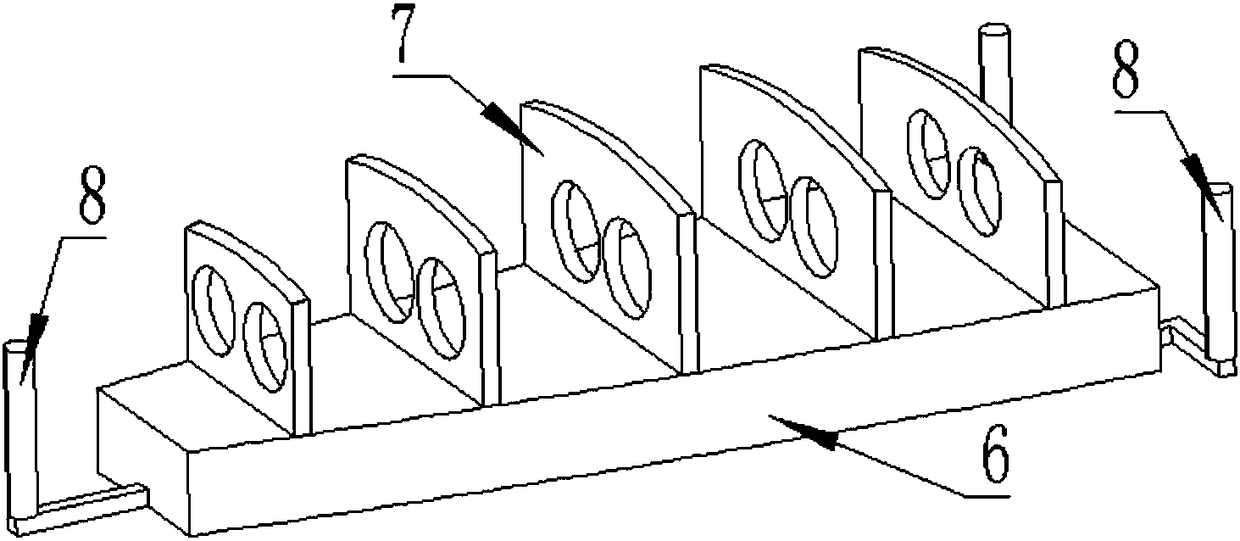

[0038] (3) Prepare the stretching machine and the stretchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com