EHV/UHV gas-insulated wall-piercing bushing center current-carrying conductor brace structure and EHV/UHV gas-insulated wall-piercing bushing

A gas-insulated, wall-penetrating bushing technology, applied in pull-in/through-type insulators, insulators, insulators, etc., can solve problems such as bushing discharge and DC system failure to operate normally, to avoid surface flashover accidents and improve operation. Safety and reliability, the effect of solving safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

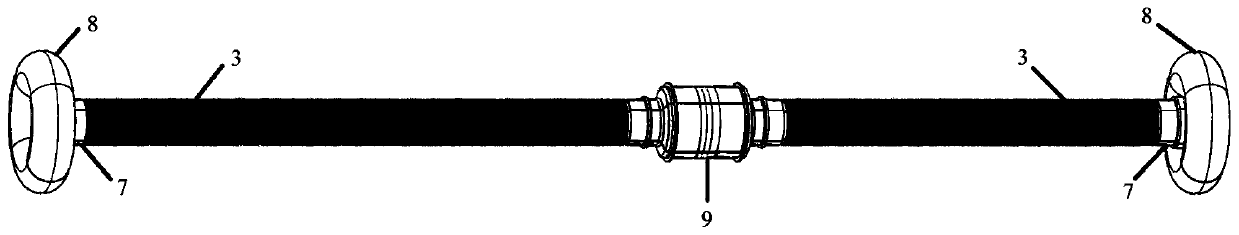

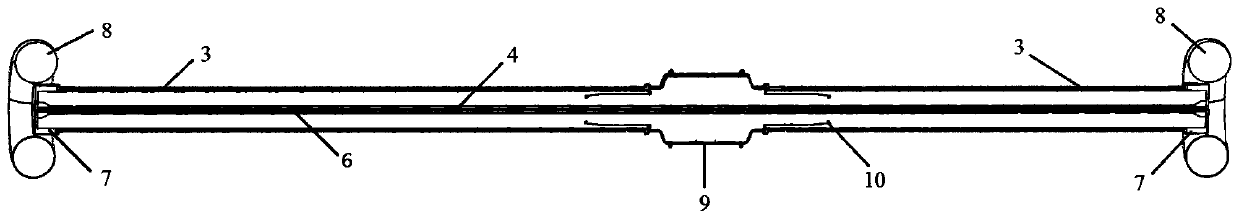

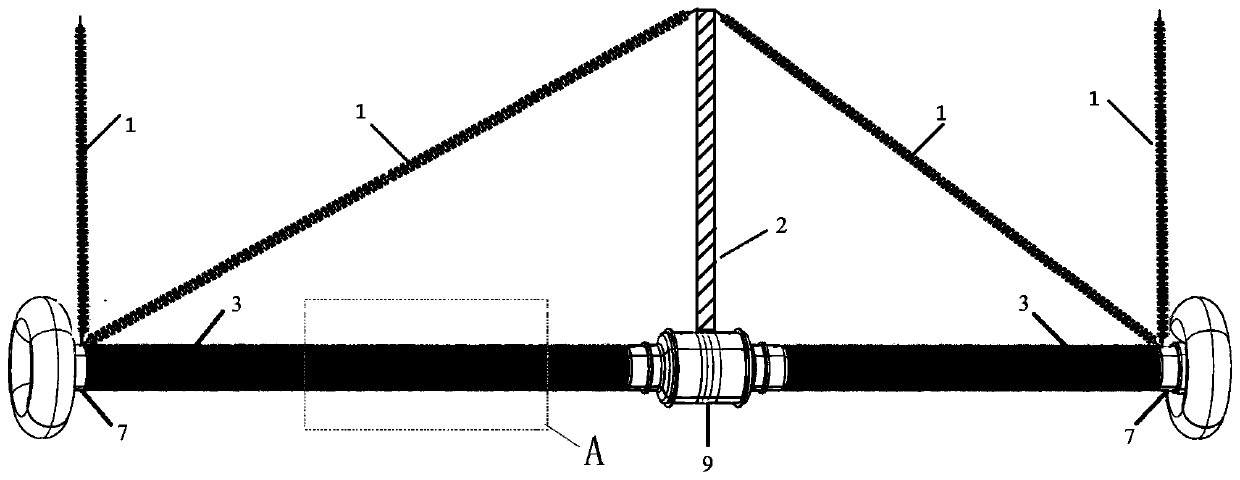

[0037] Such as image 3 , the central current-carrying conductor brace structure of the EHV gas-insulated wall-piercing bushing of the present invention also includes a rod-type suspension composite insulator for keeping the hollow composite insulator 3 of the EHV gas-insulated wall-piercing bushing horizontal 1. Rod-type suspension composite insulators 1 are connected to both ends of the EHV / UHV gas-insulated wall bushing. After the EH / UHV gas-insulated wall bushing is installed, the lower end of the rod-type suspension composite insulator 1 is connected to the end flange 7, and the upper end is connected to the wall through which the EH / UHV gas-insulated wall bushing passes. Or the top of the valve hall is fixedly connected, and the connection type is single I type, double I type or V type connection. The rod type suspension composite insulator 1 pulls up the two ends of the wall bushing to reduce the deflection of the hollow composite insulator 3 outside the wall bushing d...

Embodiment 2

[0042] Such as Figure 7 As shown, the central current-carrying conductor brace structure of the EHV gas-insulated wall bushing of the present invention also includes a rod-shaped post composite insulator 11 that keeps the hollow composite insulator 3 of the EHV gas-insulated wall bushing horizontal. , Both ends of the EHV / UHV gas-insulated wall bushing are provided with rod-shaped pillar composite insulators 11 . After the EHV / UHV gas-insulated wall bushing is installed, the upper end of the rod-shaped pillar composite insulator 11 is fixed to both ends of the wall bushing, and the lower end is fixed to the ground. The support type can be I-shaped or inverted V-shaped, and the rod-shaped pillar Composite insulator 11 is the same as the rod-shaped post composite insulator used in converter stations. It props up the two ends of the wall bushing to reduce the deflection of the external hollow composite insulator 3 due to its own weight and ensure the level of both ends and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com