Coaming bolt detection device for nuclear power plant

A technology for inspection devices and nuclear power plants, applied in nuclear power generation, nuclear engineering, nuclear reactor monitoring, etc., can solve the problems of poor flexibility and general type, poor resistance to left-right swing, occupation, etc., to improve operational flexibility and improve positioning. Efficiency, the effect of improving the field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

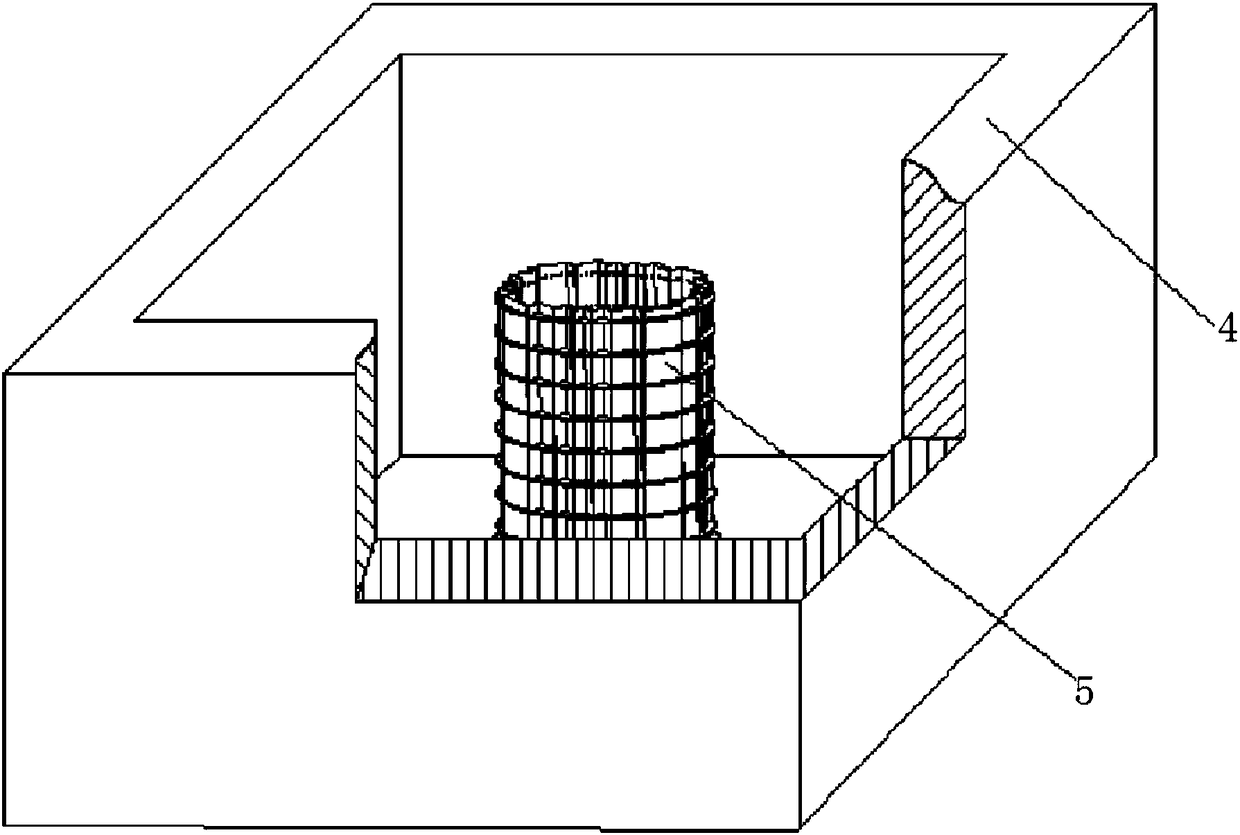

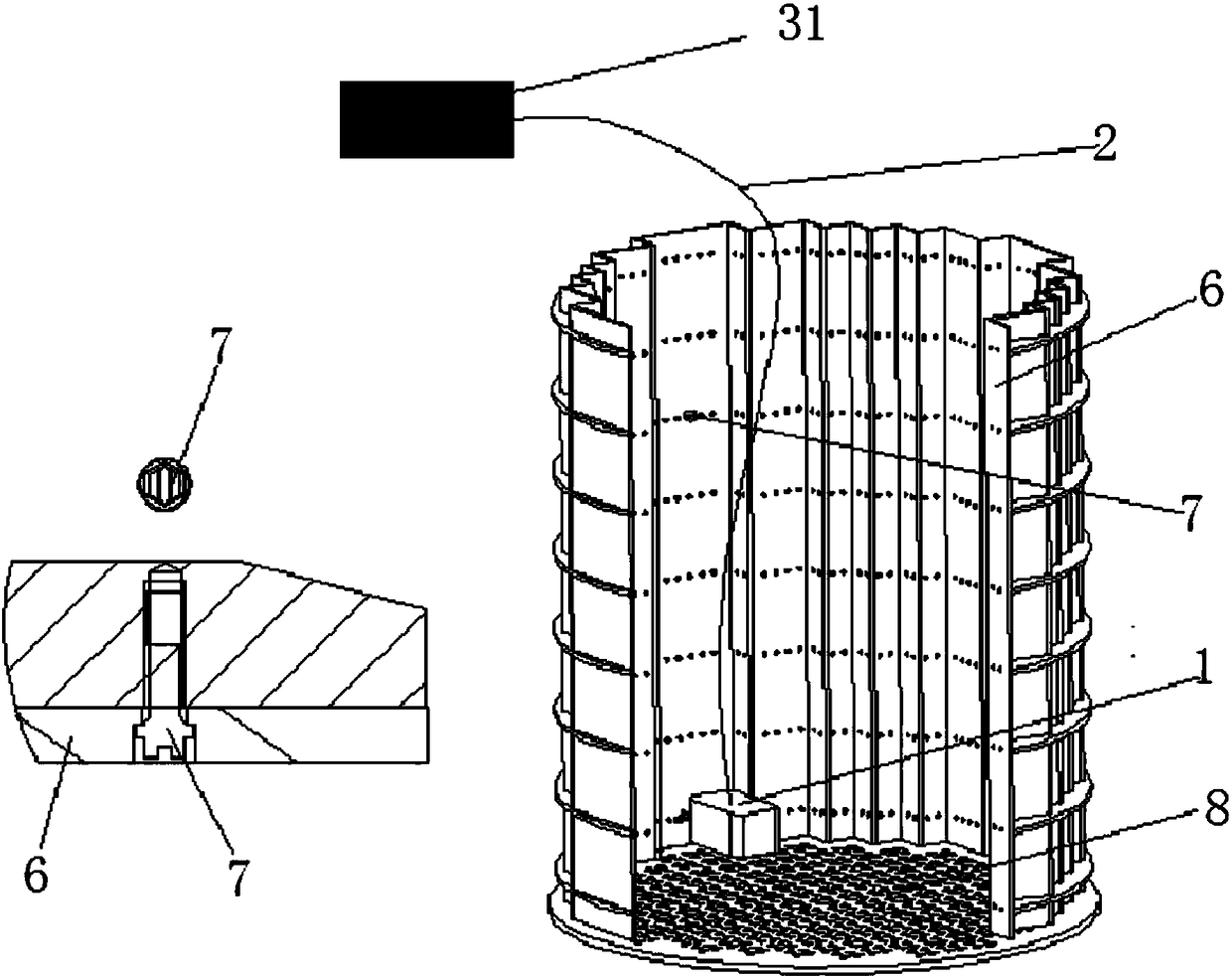

[0031] like figure 1 As shown, the plate bolt inspection device is used to inspect the nuclear power plant coaming assembly 5 placed in the pool 4, the coaming assembly surrounds the plate 6, the coaming bolt 7, and the lower grid plate 8, as shown in figure 2 As shown, the plate bolt inspection device includes a remote control system, an underwater work platform 1 and a zero-buoyancy cable 2 connected between the remote control system and the underwater work platform 1 .

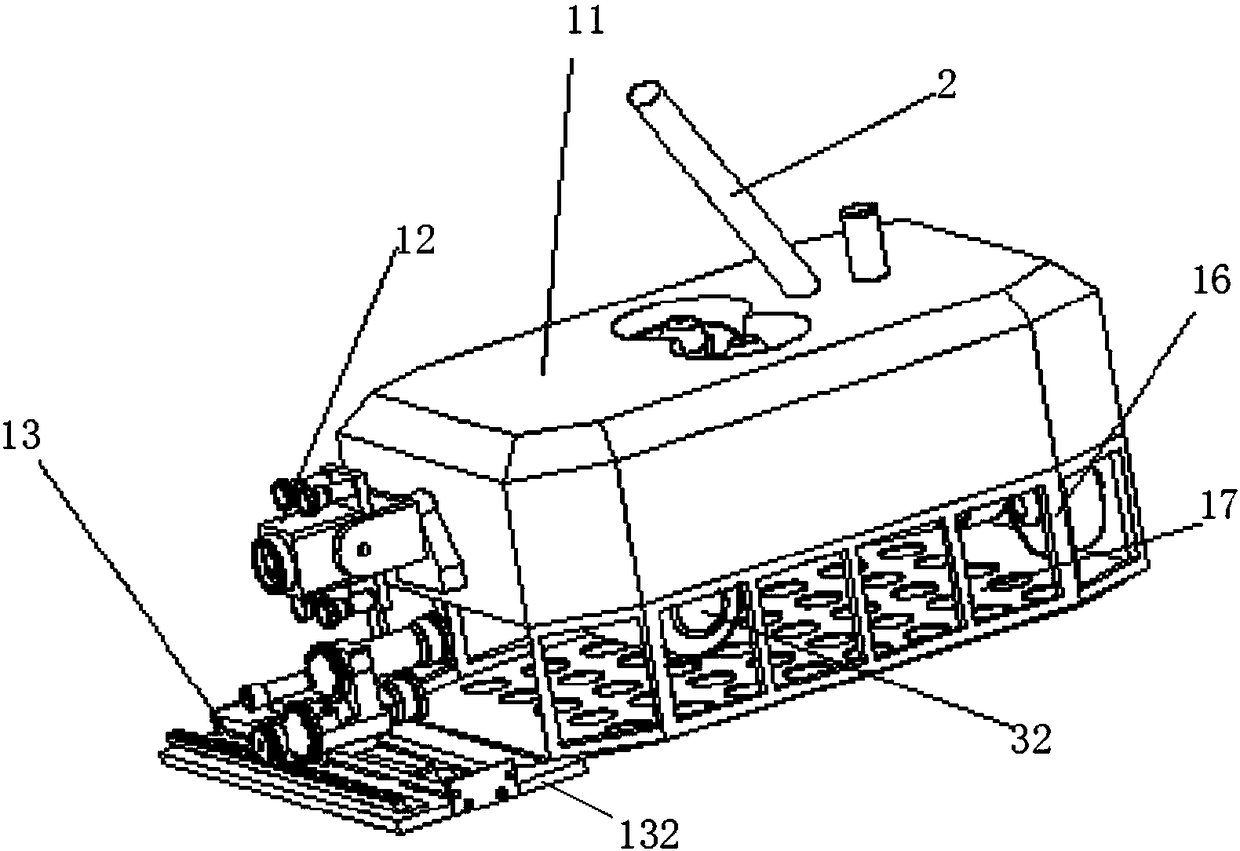

[0032] like image 3 , 4 As shown, the underwater work platform 1 includes: a buoyancy chamber 11, a camera platform 12 located on one side of the buoyancy chamber 11, an ultrasonic probe tool rack 13, a plurality of vertical propeller propellers 14, and a plurality of horizontal propeller propellers 15 , a bottom plate 17 connected to the buoyancy chamber 11 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com