Bridge inspection method

A bridge and fault detection technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as single means, low reliability, and low efficiency, and achieve the effect of high flexibility, high reliability, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

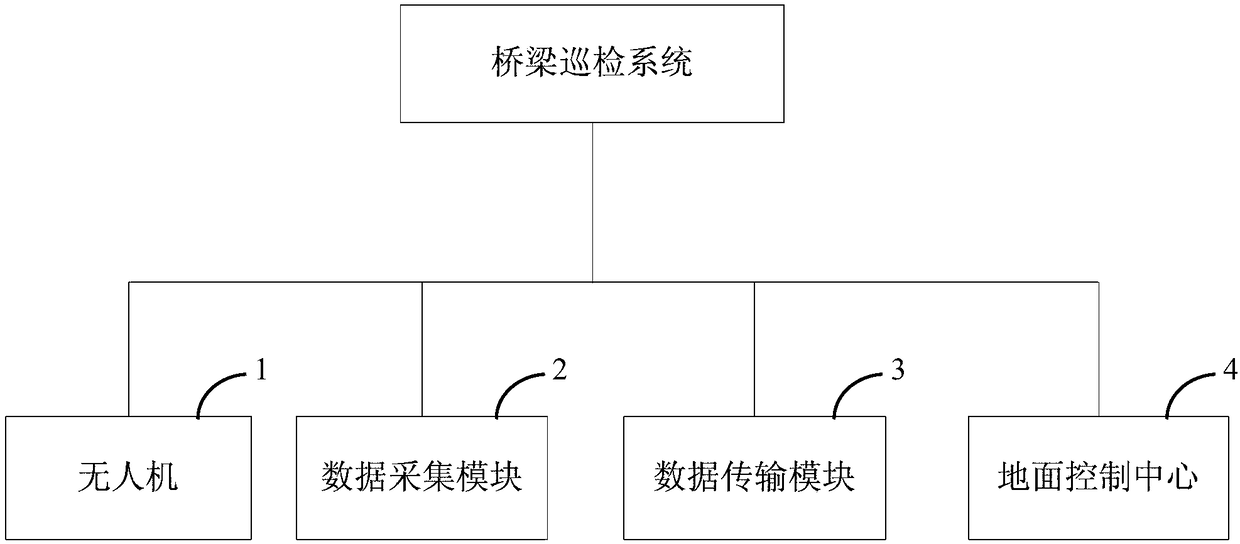

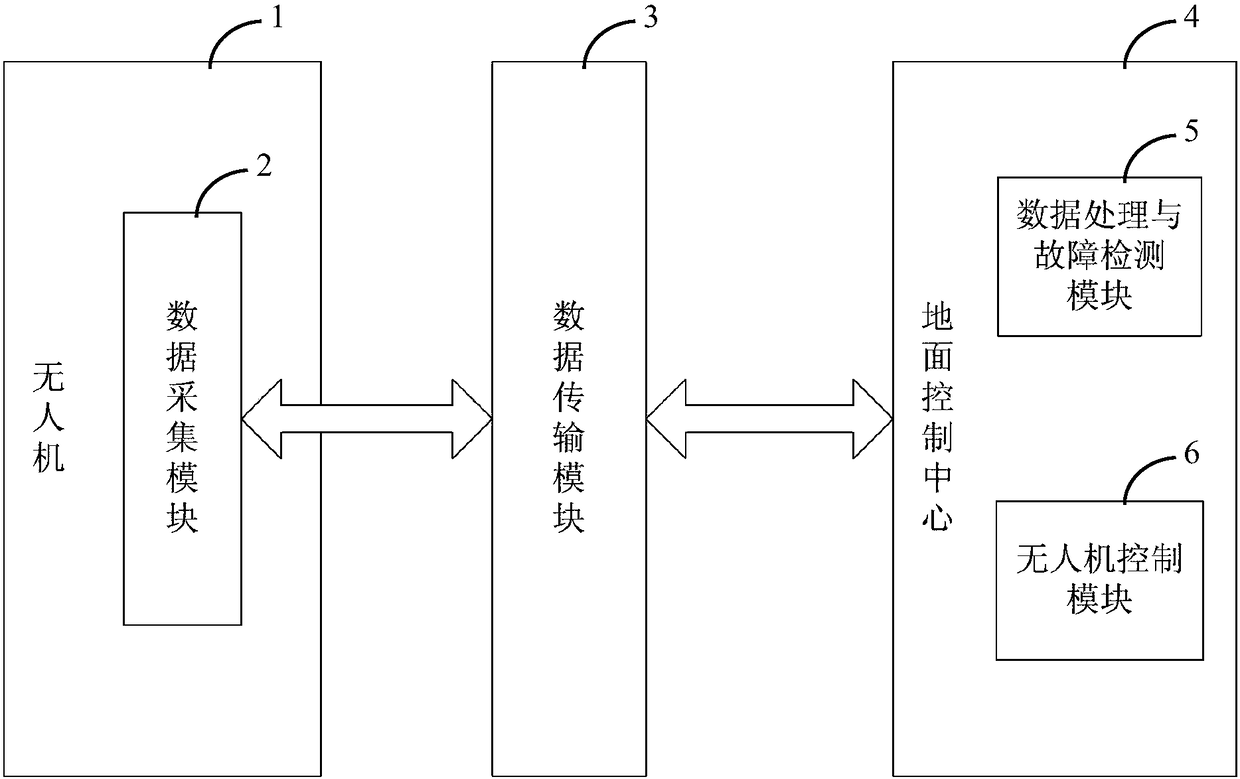

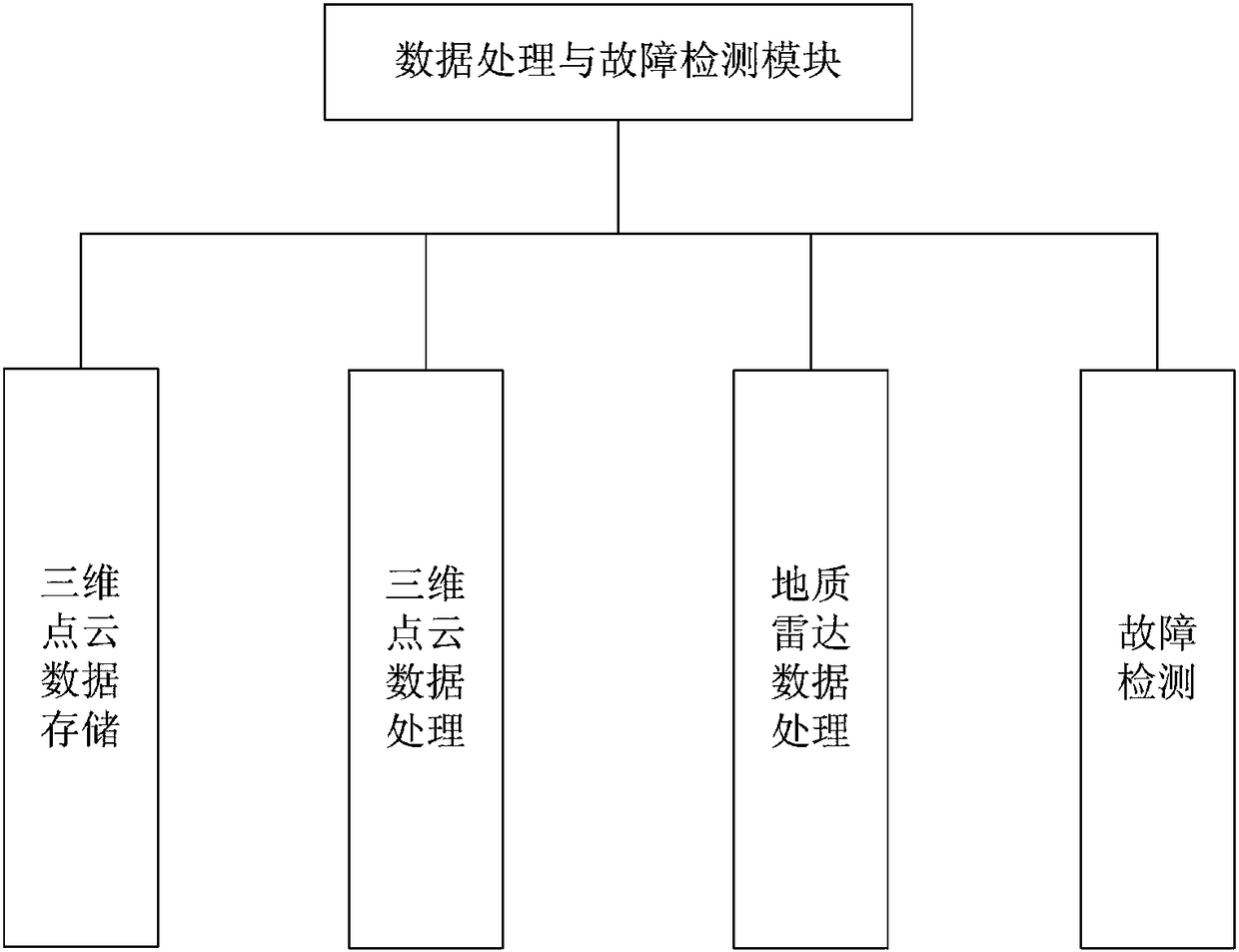

[0062] as attached figure 1 And attached figure 2 As shown, a specific embodiment of the bridge inspection system based on the method of the present invention is used for bridge 7 inspections, including: unmanned aerial vehicle 1, data transmission module 3, ground control center 4, and carried on the unmanned aerial vehicle 1 on the data acquisition module 2. The UAV 1 can be in the form of a fixed-wing UAV, a multi-rotor UAV or an unmanned helicopter. Wherein, the data collection module 2 includes various sensors mounted on the UAV 1 for collecting on-site information of the bridge. The data acquisition module 2 further includes a laser three-dimensional scanner 21 and a ground radar 22 . The UAV 1 collects on-site data of the bridge 7 through a laser three-dimensional scanner 21 and a ground radar 22 . The on-site data collected by the drone 1 is sent to the ground control center 4 through the data transmission module 3 . The data processing and fault detection module...

Embodiment 2

[0075] as attached Figure 8 As shown, a specific embodiment of the bridge inspection method of the present invention, comprising the following steps:

[0076] S101) The unmanned aerial vehicle 1 collects the field data of the bridge 7 through the laser three-dimensional scanner 21 and the ground radar 22 carried on it;

[0077] S102) The on-site data collected by the UAV 1 is sent to the ground control center 4 through the data transmission module 3;

[0078] S103) The data processing and fault detection module 5 of the ground control center 4 processes the laser three-dimensional scanning data collected by the laser three-dimensional scanner 21 to complete the three-dimensional modeling of the detected area of the bridge 7, and at the same time, the radar echo collected by the ground radar 22 wave data processing;

[0079] S104) The data processing and fault detection module 5 detects the defect and the position of the defect of the bridge 7 by analyzing the three-dimens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com