An inner tank parameter control device of an electric water heater

An electric water heater, parameter control technology, applied in the field of tank parameter control device, can solve the problems of safety pressure relief valve dripping, difficult control, automatic control of tank pressure, etc., to achieve intelligent control, effective and reliable monitoring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

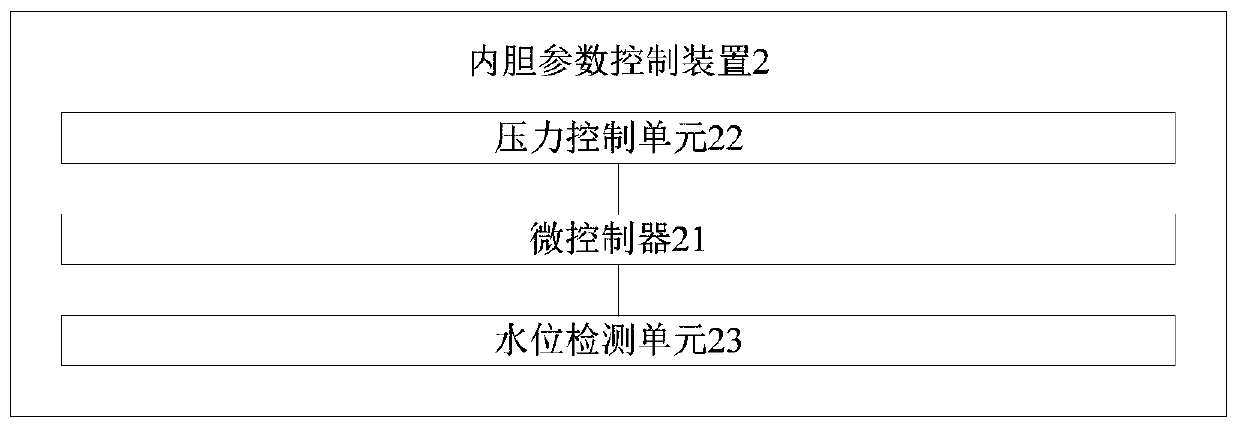

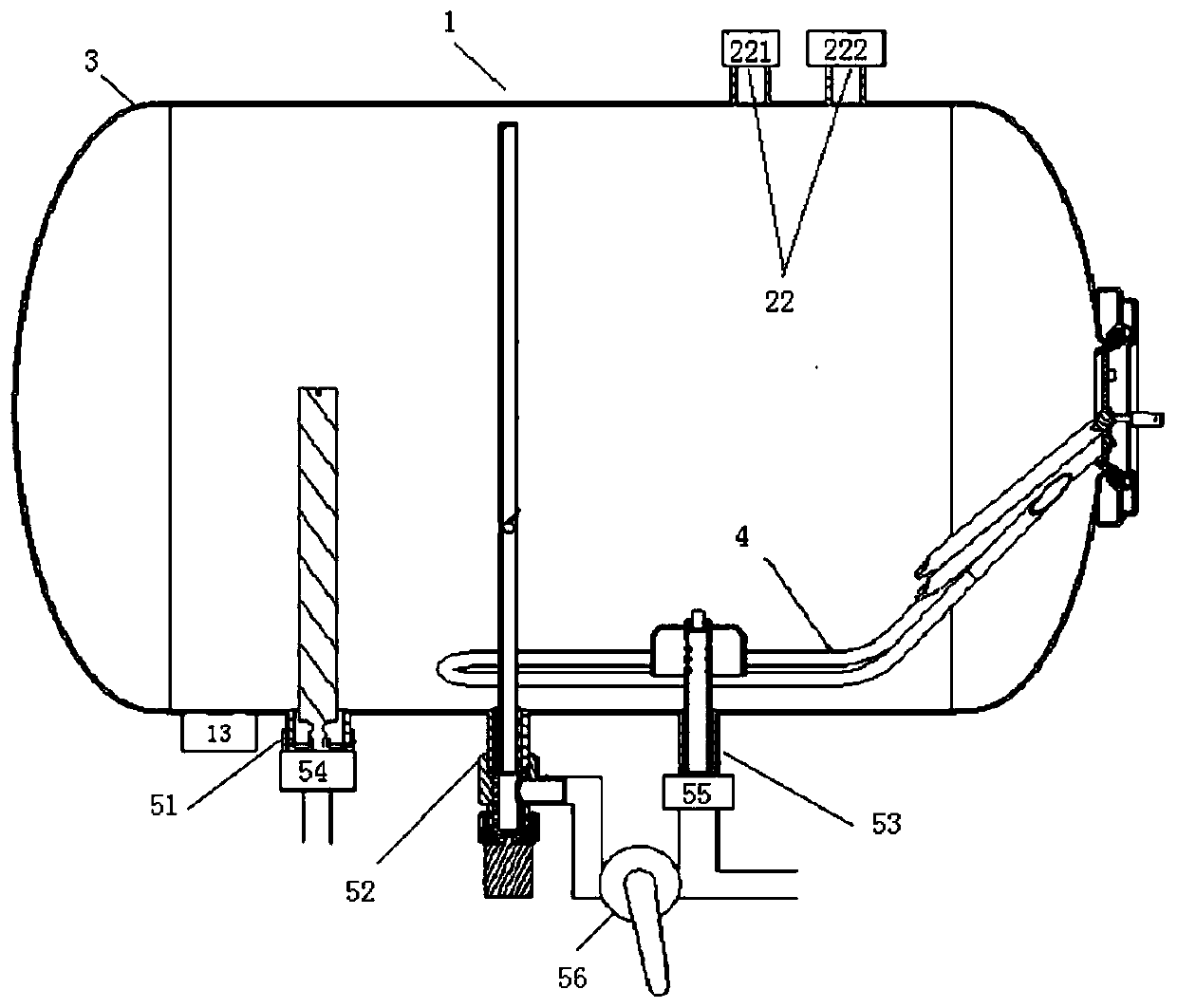

[0059] A liner parameter control device 2 of an electric water heater 1, such as figure 1 As shown, the electric water heater 1 includes: an inner tank 3, a heating assembly 4 disposed in the inner tank 3, and a water inlet and outlet control unit 5 disposed on the inner tank 3, the inner tank parameters include the pressure value in the inner tank 3, The device 2 includes: a microcontroller 21 and a pressure control unit 22 arranged outside the inner tank;

[0060] The microcontroller 21 is used to control the water inlet and outlet control unit 5, so that the electric water heater works in different working modes; wherein, the working modes can include: the whole tank heating mode, the half tank heating mode and the whole tank heating mode The variable capacity mode when switching between the half tank heating mode;

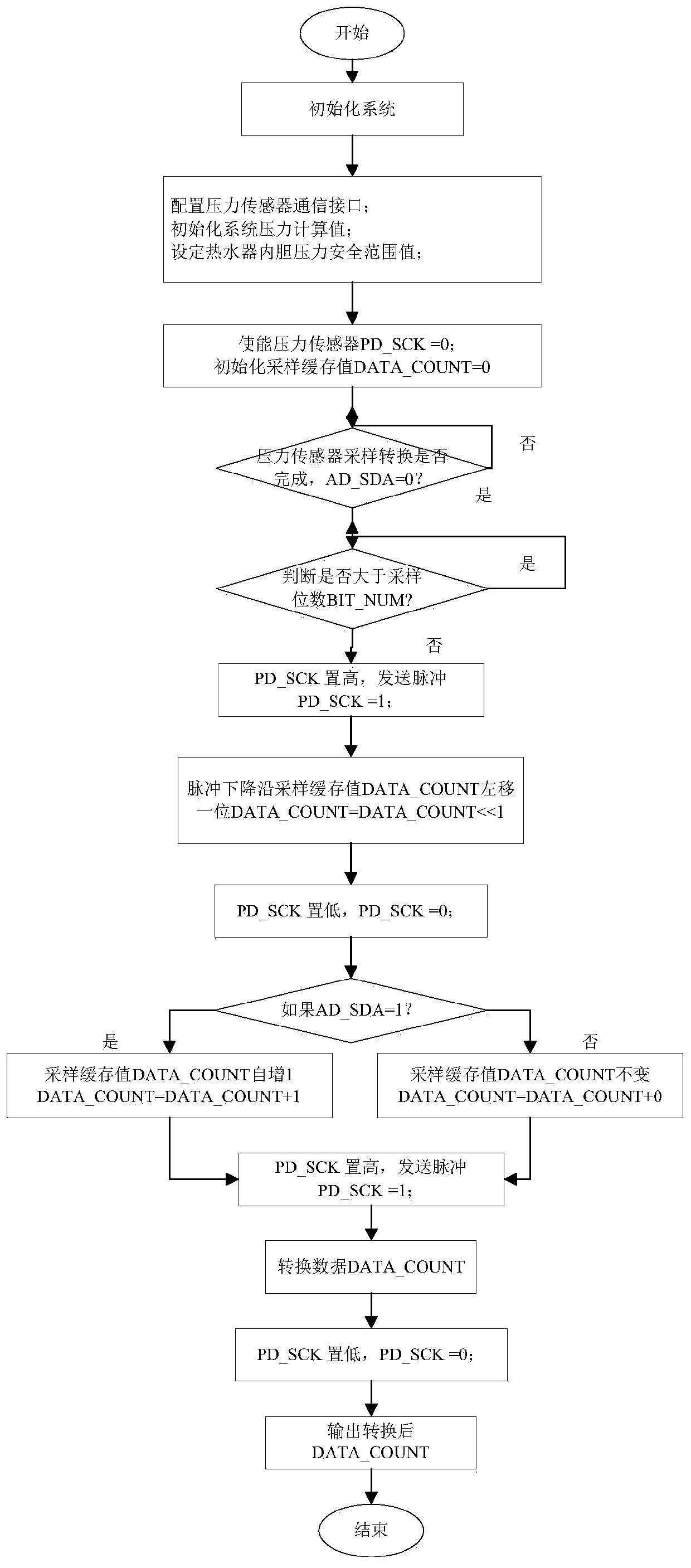

[0061] The pressure control unit 22 is used to detect the pressure value in the inner tank 3 in real time when the electric water heater 1 is in different wor...

Embodiment 2

[0066] This embodiment briefly introduces the composition and structure of the water inflow and outflow control unit 5 on the basis of the first embodiment.

[0067] Optionally, as in figure 2 As shown, the water inlet and outlet control unit 5 may include: a sewage discharge assembly 51, a water outlet assembly 52, a water inlet assembly 53, a first control switch 54, a second control switch 55 and a third control switch 56;

[0068] Wherein, the first control switch 54 is connected with the blowdown assembly 51, and is used to control the blowdown assembly 51 to open or close according to the control instruction of the microcontroller 21;

[0069] The second control switch 55 is connected with the water inlet assembly 53, and is used to control the opening or closing of the water inlet assembly 53 according to the control instruction of the microcontroller 21;

[0070] The third control switch 56 is connected with the water outlet assembly 52 and is used for selectively co...

Embodiment 3

[0075] This embodiment briefly introduces the composition and structure of the pressure control unit 22 on the basis of the first or second embodiment.

[0076] Optionally, the pressure control unit 22 may include: a pressure sensor 221 and an air pump assembly 222 respectively connected to the microcontroller 21;

[0077] The pressure sensor 221 is used to detect the pressure value in the inner tank in real time;

[0078] The air pump component 222 is used to pressurize the inner tank or release the pressure of the inner tank according to the control of the microcontroller, so as to balance the pressure difference between the inner tank and the outside; it is also used to Pressurize the inner tank so that the water in the inner tank can be drained.

[0079] In the embodiment of the present invention, multiple (such as 4) variable resistors with high precision and low temperature drift can be used to form a bridge circuit to form a pressure sensor probe, which is closely atta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com