Method for producing rayon by using PTT and PET

A production method and a technology for elastic filaments, which can be applied in the directions of melt spinning, filament/thread forming, and conjugated synthetic polymer rayon, etc. The problem of high cost of elastic wire, to achieve the effect of improving spinnability, good crimp elasticity, and high product grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

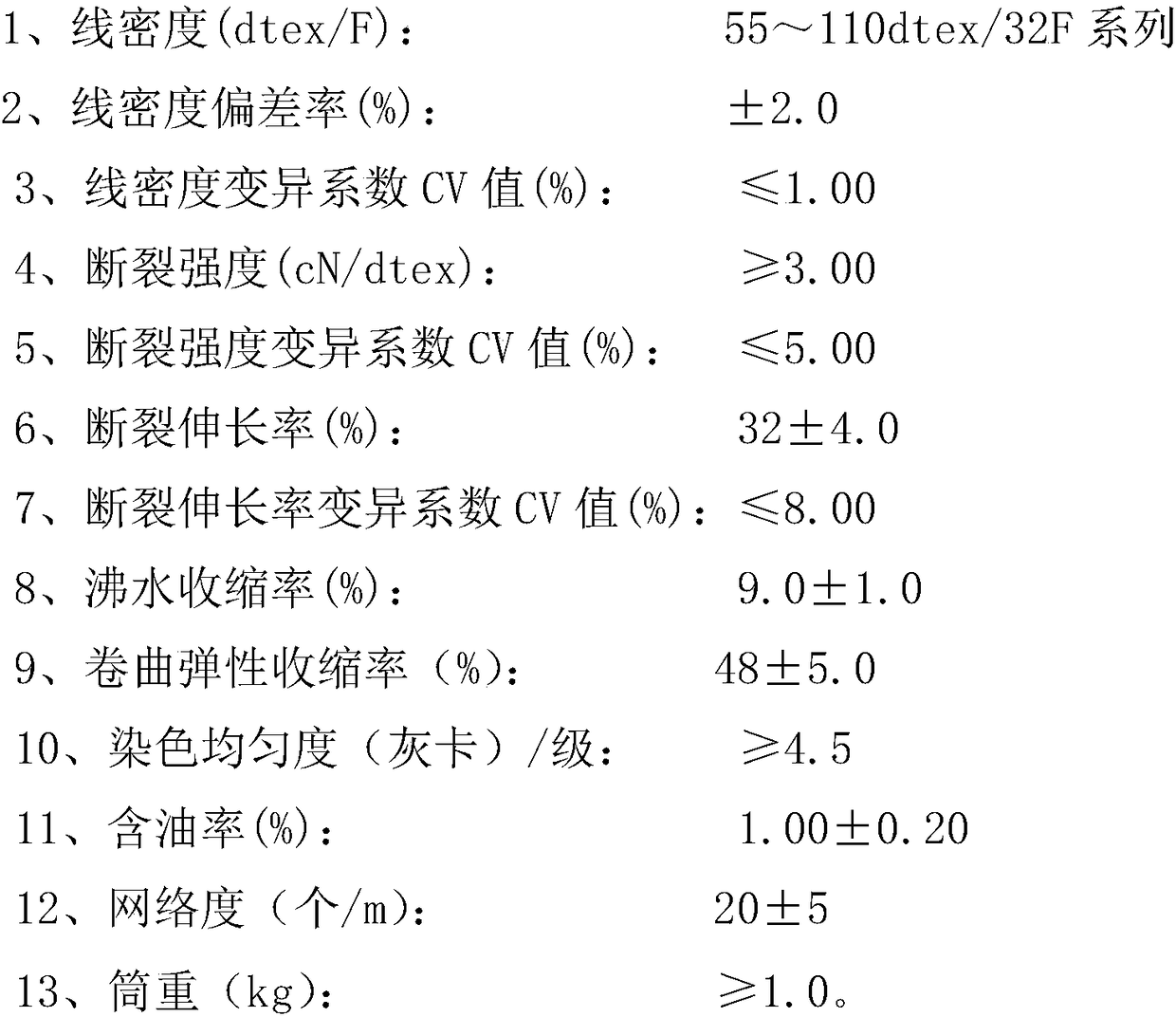

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with regard to specific embodiment:

[0017] A kind of production method that utilizes PTT and PET to produce cable elastic yarn, at first select the PTT raw material of 41-55 parts by mass and the PET raw material of 41-55 parts, the PET raw material selects the PET chip of low viscosity, and its viscosity is not higher than 0.53dl / g; The PTT raw material is viscosified through the drum, so that the viscosity of the PTT chip is higher than 1.18dl / g, and the viscosity difference between the PTT raw material and the PET raw material is maximized, and then formed by melt spinning and stretching. In this example, the PET raw material is made of Shanghai Petrochemical PET chips with a viscosity of 0.5 dl / g lower than that of conventional PET chips of 0.63 dl / g, and the number of parts by mass is 50 parts; the PTT raw material is made of U.S. DuPont's PTT chip, the mass number is 50 parts.

[0018] The specific productio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com