High-molecular luminescent material of terbium-complex-grafted modified ethylene-acrylic acid copolymer and preparation method thereof

An ethylene acrylic acid copolymer, graft modification technology, applied in the directions of luminescent materials, chemical instruments and methods, can solve the problems of poor compatibility between rare earth fluorescent complexes and substrates, and achieve low price, mild reaction conditions, and thermal stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

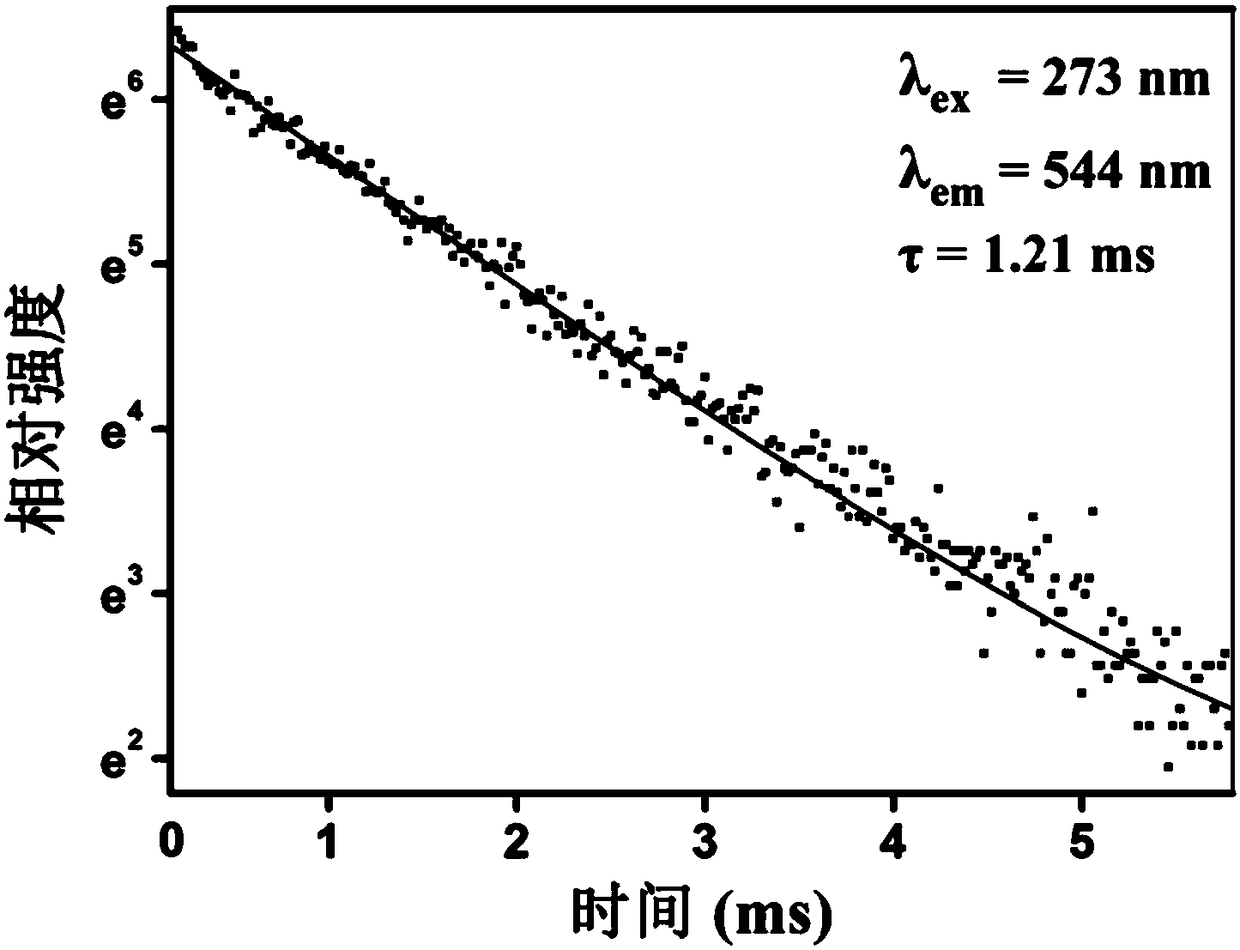

Embodiment 1

[0042] This implementation case shows a preparation method of a polymer luminescent material grafted with terbium complexes to modify ethylene acrylic acid copolymers, including:

[0043] (1) Weigh 0.37g terbium chloride hexahydrate, 0.42g p-aminobenzoic acid and 0.18g o-phenanthroline, dissolve them in ethanol respectively, mix the three solutions, and adjust the pH using 1mol / L sodium hydroxide solution to 5, stirred at 60° C. for 5 hours; dried in a vacuum oven at 60° C. for 5 hours to obtain a rare earth complex.

[0044] (2) Take 10cm 2 The ethylene acrylic acid copolymer film is placed in a 3% mass concentration of phosphorus pentachloride in dichloromethane solution, stirred and reacted for 24 hours, and dried in air to obtain the acyl chloride ethylene acrylic acid copolymer film.

[0045](3) Weigh 0.2g of rare earth complex, dissolve it in 20g of N,N-dimethylformamide, add 4g of triethylamine, add acyl chloride ethylene acrylic acid copolymer film, heat up to 60°C, k...

Embodiment 2

[0052] This implementation case shows a preparation method of a polymer luminescent material grafted with terbium complexes to modify ethylene acrylic acid copolymers, including:

[0053] (1) Weigh 0.37g terbium chloride hexahydrate, 0.53g p-aminobenzenesulfonic acid and 0.15g 8-hydroxyquinoline, dissolve them in ethanol respectively, mix the three solutions, and use 1mol / L potassium hydroxide solution Adjust the pH to 5, stir at 60° C. for 5 hours; dry in a vacuum oven at 60° C. for 5 hours to obtain a rare earth complex.

[0054] (2) Take 10cm 2 The ethylene acrylic acid copolymer film is placed in a 3% mass concentration of phosphorus pentachloride in dichloromethane solution, stirred and reacted for 24 hours, and dried in air to obtain the acyl chloride ethylene acrylic acid copolymer film.

[0055] (3) Weigh 0.1g of rare earth complex, dissolve it in 20g of N,N-dimethylformamide, add 2g of triethylamine, add acyl chloride ethylene acrylic acid copolymer film, heat up to ...

Embodiment 3

[0057] This implementation case shows a preparation method of a polymer luminescent material grafted with terbium complexes to modify ethylene acrylic acid copolymers, including:

[0058] (1) Weigh 0.37g terbium chloride hexahydrate, 0.50g ethyl p-aminobenzoate and 0.24g dibenzoylmethane, dissolve them in ethanol respectively, mix the three solutions, and use 1mol / L sodium bicarbonate The pH of the solution was adjusted to 5, stirred at 60° C. for 5 hours, and dried in a vacuum oven at 60° C. for 5 hours to obtain a rare earth complex.

[0059] (2) Take 10cm 2 The ethylene acrylic acid copolymer film is placed in a 3% mass concentration of phosphorus pentachloride in dichloromethane solution, stirred and reacted for 24 hours, and dried in air to obtain the acyl chloride ethylene acrylic acid copolymer film.

[0060] (3) Weigh 0.2g of rare earth complex, dissolve it in 30g of N,N-dimethylformamide, add 3g of triethylamine, add acyl chloride ethylene acrylic acid copolymer film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com