Semi-lean solution absorption low-temperature methanol washing system and method

A low-temperature methanol washing and semi-poor liquid technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of increasing the heat load of the methanol-water separation tower, wasting the cooling capacity of the system, and high water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

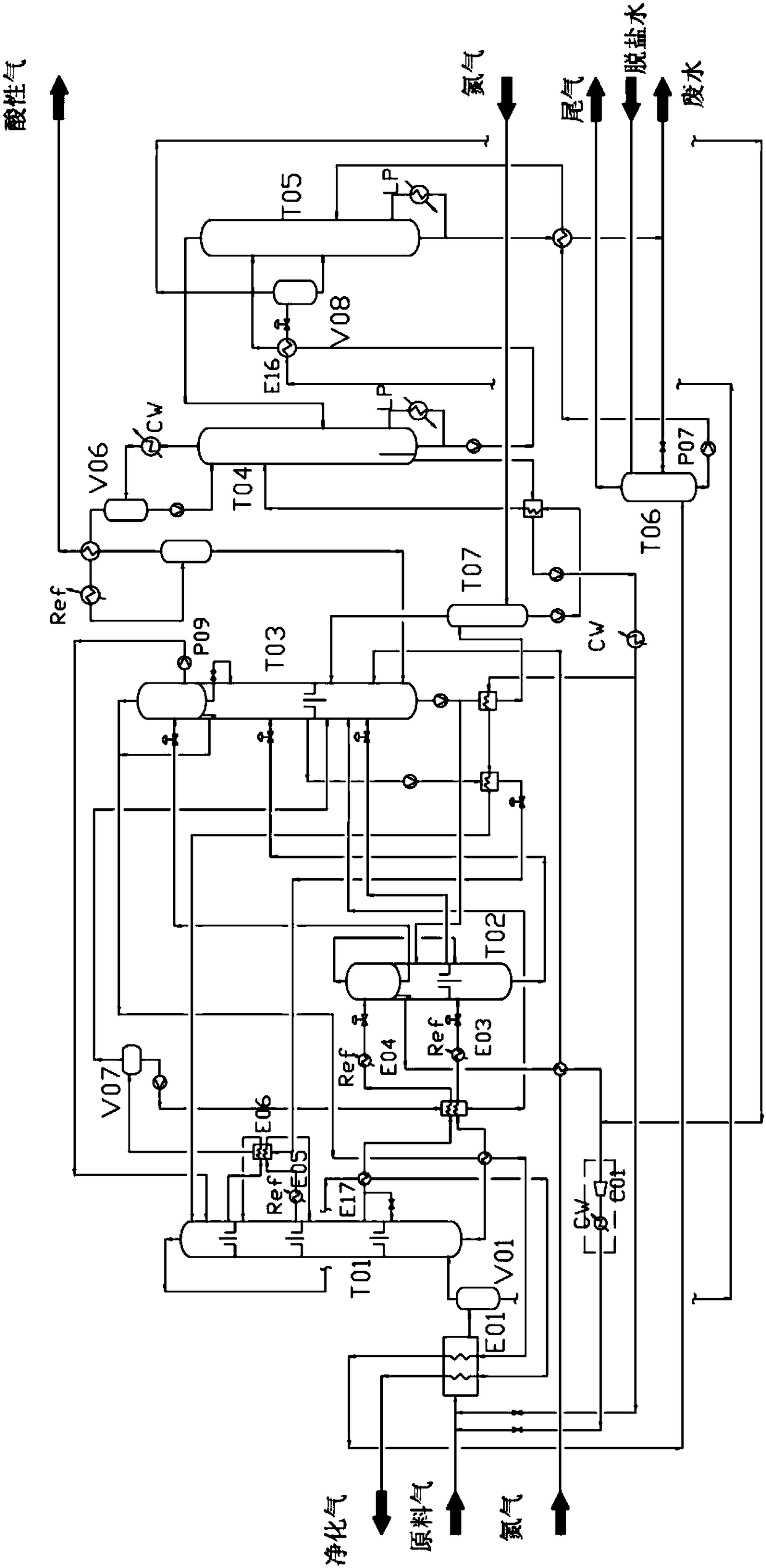

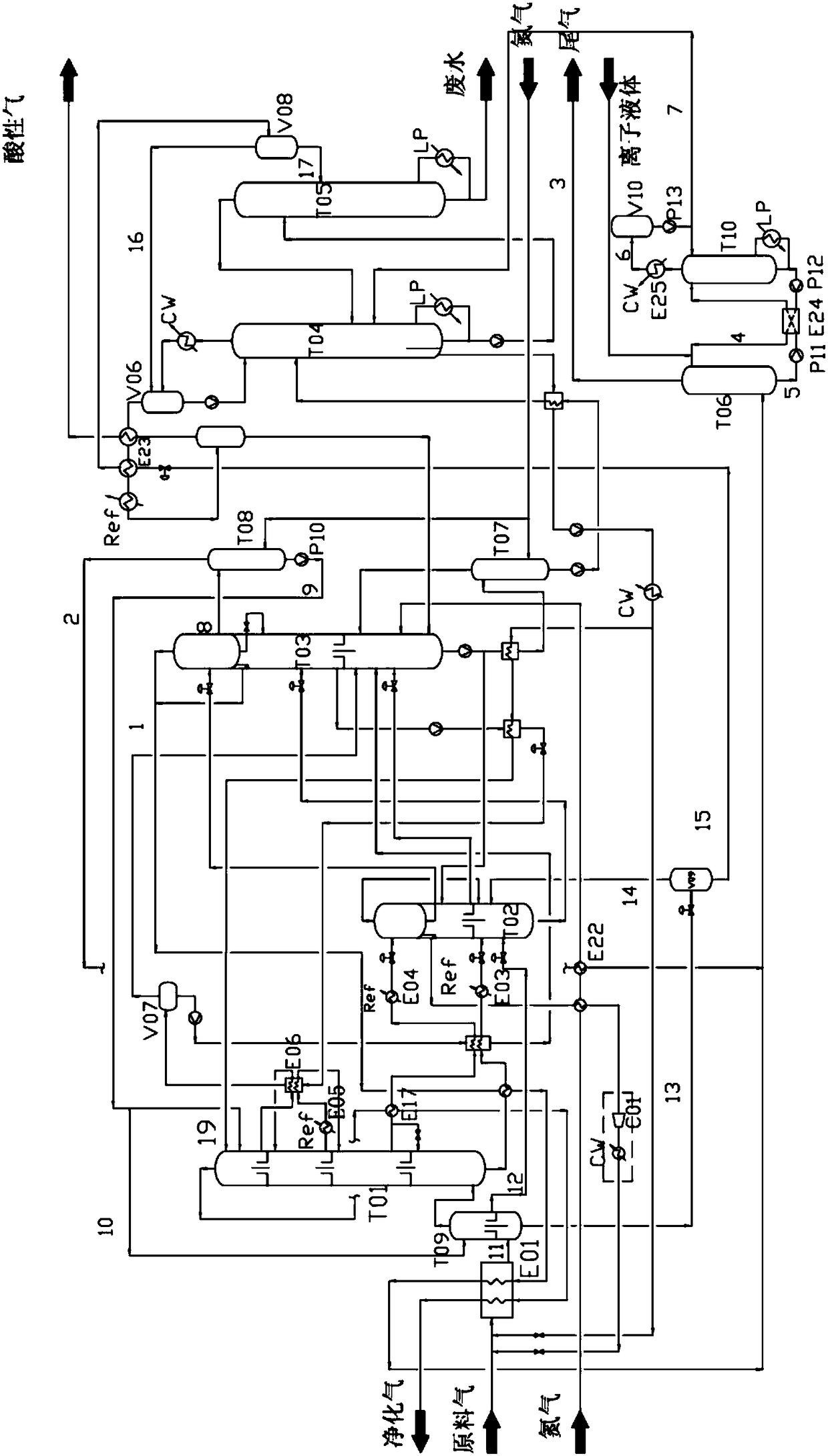

[0063] This embodiment provides a semi-poor liquid absorption low-temperature methanol washing system, and its process flow chart is as follows figure 2 said, from figure 2 As can be seen, the system includes:

[0064] Raw gas cooler E01, raw material main washing tower T01, flash evaporation and lean methanol stripping system, methanol regeneration system, tail gas scrubbing system and heat exchange network, among which, the flash evaporation and lean methanol stripping system mainly includes medium pressure flash tower T02, concentration tower T03 and the flash tank at the top of the tower; the methanol regeneration system mainly includes the thermal regeneration tower T104, the H 2 S gas separation tank V06, methanol water separation tower T05 and methanol / CO 2 Flash tank V08; the tail gas scrubbing system mainly includes tail gas scrubber T06;

[0065] The main difference between the semi-lean liquid absorption low-temperature methanol washing system provided in this ...

Embodiment 2

[0072] This embodiment provides a semi-poor liquid absorption low-temperature methanol washing method, which is realized by using the system provided in Embodiment 1, and the method includes the following steps:

[0073] The logistics data in this example are all the process simulation calculation results of 350,000 tons / year coal gasification to methanol scale.

[0074] 1-butyl-3-methylimidazolium tetrafluoroborate ([BMIM][BF 4 ]) The ionic liquid is prepared as an aqueous solution with a mass fraction of 95%. The tail gas (34730Nm) after the tail gas 1 and the stripping tail gas 2 of the semi-lean liquid stripping tower T08 from the top of the concentration tower T03 and the flash tank on the top are combined 3 / h, 30°C, 0.07MPaG), the methanol content is 304mg / Nm 3 , into the bottom of the tail gas absorption tower T06, the pressure inside the tower is 0.03MPaG. The tail gas absorption tower is a spray tower. Tail gas enters the absorption tower from the gas inlet at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com