Porous silk fibroin spinal cord scaffold with directional release function, its preparation method, preparation mold and application

A technology of porous silk and spinal cord, applied in the field of spinal cord stent, can solve the problems of complex and time-consuming directional freezing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0039] 1. Preparation of silk fibroin aqueous solution

[0040] Take the silkworm cocoon from which the chrysalis has been removed, and add 0.02mol / L Na 2 CO 3 Water solution, boiled for 30 minutes, took out, wrung out, rinsed with distilled water; repeated the above operation twice, dried in a 60°C oven for 24 hours, and kept loosening in the middle to obtain degummed silk; put the degummed silk in 9.3mol / L LiBr aqueous solution , the mass ratio of degummed silk to 9.3mol / L LiBr aqueous solution is 1:5, keep warm at 60°C until the degummed silk is completely dissolved, put it into a dialysis bag with a cut-off molecular weight of 8,000-14,000 Daltons, and dialyze with tap water at 4°C for two days, Dialyze with deionized water at 4°C for one day (change the water every 1 hour on the first day, and every 2 hours on the next two days, and the interval between water changes at night should not be too long). After dialysis, the solution is filtered through 8 layers of gauze and ...

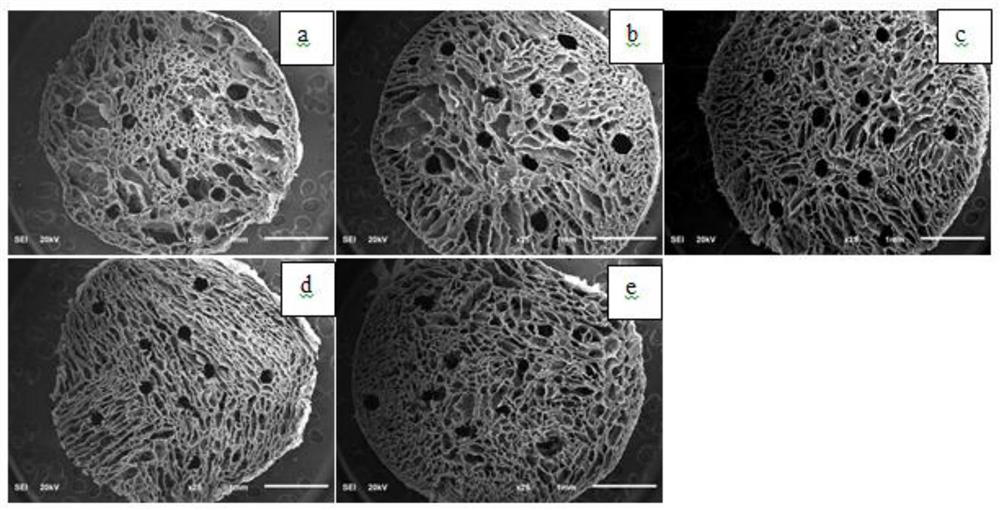

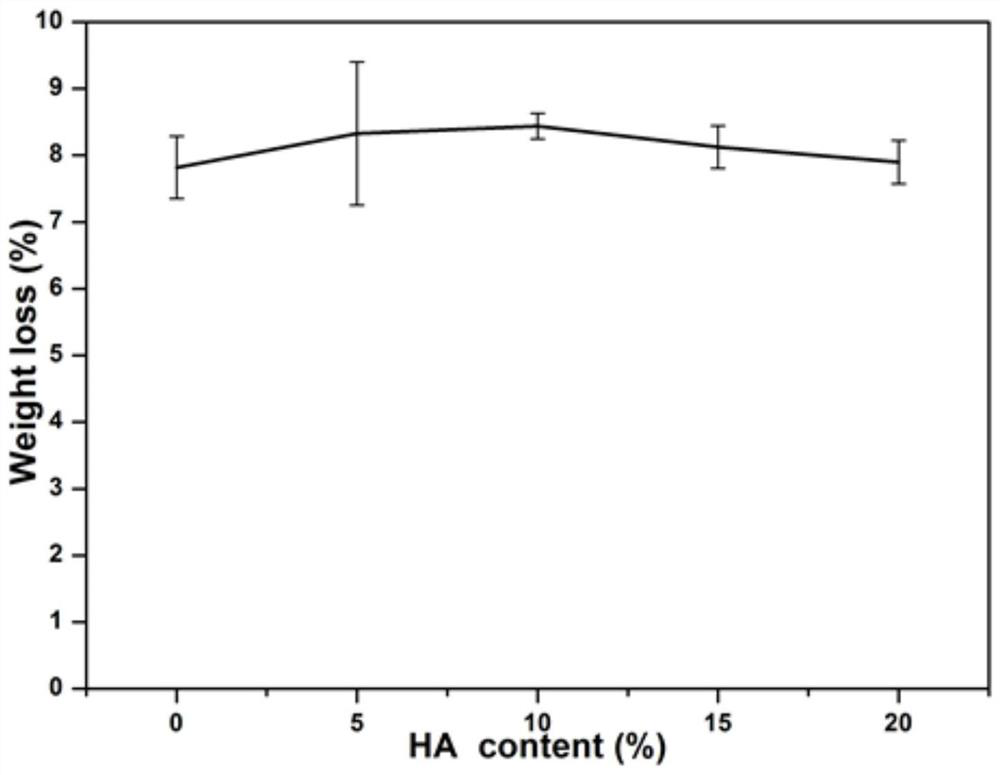

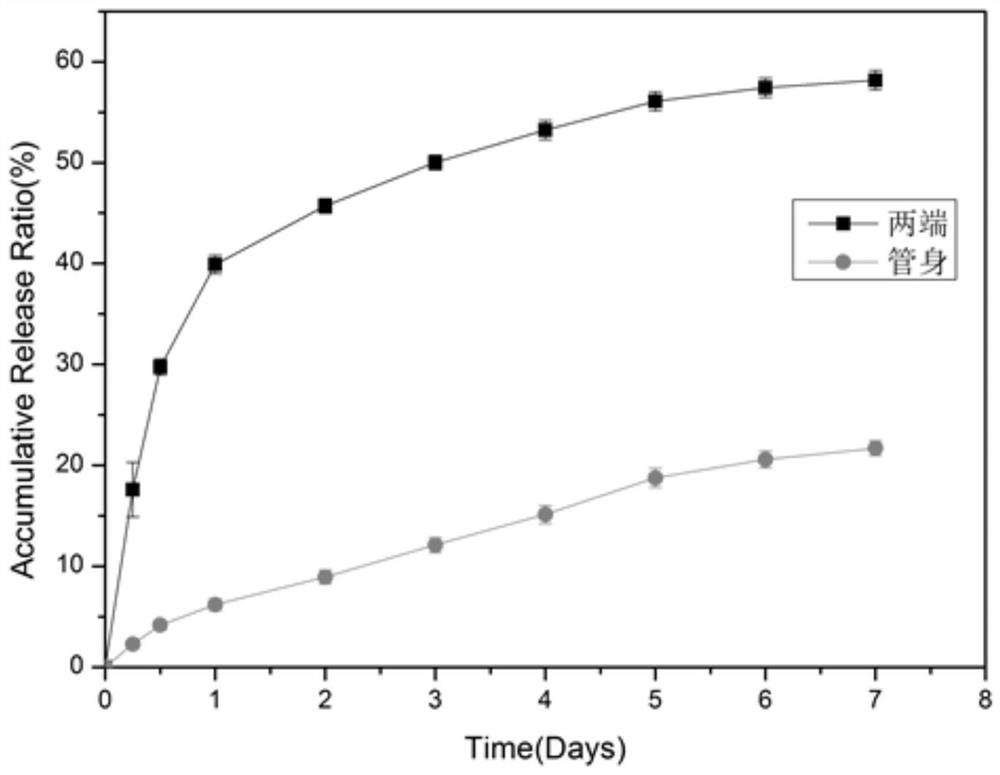

Embodiment 1

[0046] In the step 1 of preparing the scaffold in Example 1, the total concentration of the mixed solution is 5%, and 20ml of the mixed solution of SF / HA=95:5 is added, and then EDC, 10% NHS, 10% NHS, 0.012g MES (the content of EDC, NHS, MES is relative to the content of SF in the SF / HA mixed solution), fully stirred for 1h under ice bath. Inject into the mold with a syringe (the number of needles is 10), and freeze in a refrigerator at -80°C for 24 hours. The above-mentioned frozen samples were taken out from the mold, placed in a freeze dryer, and dried under reduced pressure for 48 hours to obtain a multi-channel SF / HA porous scaffold.

Embodiment 2

[0048] In the step 1 of preparing the scaffold in Example 1, the total concentration of the mixed solution is 5%, and 20ml of the mixed solution of SF / HA=90:10 is added, and then EDC, 10% NHS, 10% NHS, 0.012g MES (the content of EDC, NHS, MES is relative to the content of SF in the SF / HA mixed solution), fully stirred for 1h under ice bath. Inject into the mold with a syringe (the number of needles is 10), and freeze in a refrigerator at -80°C for 24 hours. The above-mentioned frozen samples were taken out from the mold, placed in a freeze dryer, and dried under reduced pressure for 48 hours to obtain a multi-channel SF / HA porous scaffold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com