Paper-making reconstituted tobacco preparation method and method for improving coating liquid absorbability of paper-making reconstituted tobacco substrate

A technology for reconstituting tobacco leaves and making paper, which is applied in the preparation of tobacco, tobacco, and applications, can solve the problems of loss of coating liquid components, high slag content in the coating liquid, and easy to find, etc. Liquid capacity, the effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

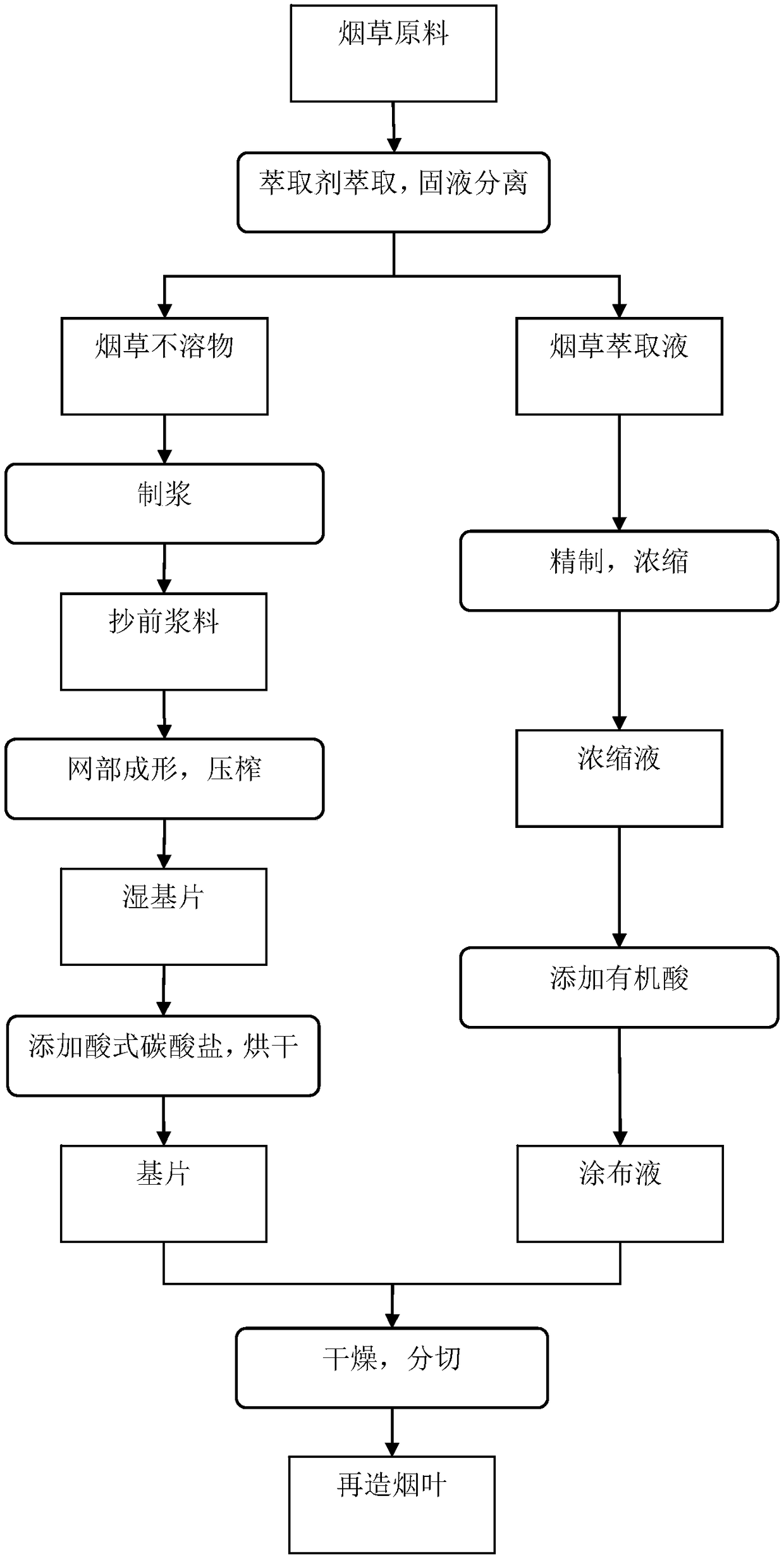

[0050] The invention provides a method for preparing reconstituted tobacco leaves by a papermaking method and a method for improving the absorbability of a substrate of a reconstituted tobacco leaf by a papermaking method to a coating liquid. Liquid absorbency. figure 1 It is shown as a process flow chart of the reconstituted tobacco leaf by the papermaking method of the present invention. As shown in the figure, the preparation method of the reconstituted tobacco leaf by the papermaking method comprises the following steps:

[0051] 1) The tobacco raw material is extracted with an extractant and then separated into solid and liquid to obtain tobacco insoluble matter and tobacco extract.

[0052] Specifically, the tobacco raw materials are tobacco stems, tobacco sheets and tobacco powder, and the three raw materials are mixed according to the mass ratio of (4-8):(1-4):(1-4), and then the total weight of the raw materials is added 4-7 times of water, soak and extract at 40-80°...

Embodiment 1

[0062] 1) After the tobacco raw material is extracted with an extractant, the solid-liquid separation is obtained to obtain tobacco insoluble matter and tobacco extract. The tobacco raw material is tobacco stem, tobacco sheet and tobacco dust, and the mass ratio of tobacco stem, tobacco sheet and tobacco dust is 6: 3:1, the extraction agent is water, the amount of water is 7 times the total weight of tobacco raw materials, the extraction temperature is 60°C, and the extraction time is 40 minutes;

[0063] 2) adding water to the tobacco insolubles obtained in step 1) to thicken to 6wt%, and then beating with a high-concentration mill to obtain a pre-sheet pulp, and the beating degree is controlled at 35°SR. The obtained pre-printing slurry is formed by a dynamic sheet machine, and then pressed to obtain a wet substrate;

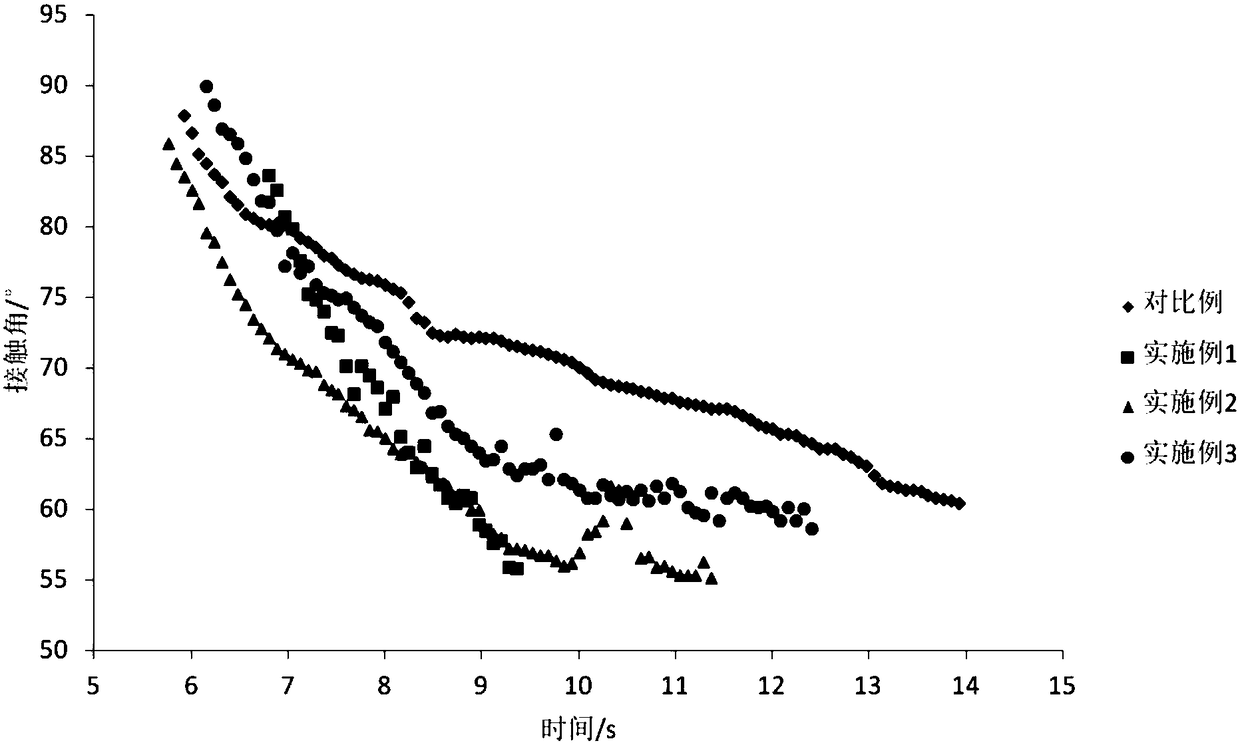

[0064] 3) Dry the wet substrate obtained in step 2) at 100°C for 3 minutes, take it out and spray with saturated potassium bicarbonate solution, and control t...

Embodiment 2

[0068] 1) After the tobacco raw material is extracted with an extractant, the solid-liquid separation is obtained to obtain tobacco insoluble matter and tobacco extract. The tobacco raw material is tobacco stem, tobacco sheet and tobacco dust, and the mass ratio of tobacco stem, tobacco sheet and tobacco dust is 6: 3:1, the extraction agent is water, the amount of water is 7 times the total weight of tobacco raw materials, the extraction temperature is 60°C, and the extraction time is 40 minutes;

[0069] 2) adding water to the tobacco insolubles obtained in step 1) to thicken to 6wt%, and then beating with a high-concentration mill to obtain a pre-sheet pulp, and the beating degree is controlled at 35°SR. The obtained pre-printing slurry is formed by a dynamic sheet machine, and then pressed to obtain a wet substrate;

[0070] 3) Dry the wet substrate obtained in step 2) at 150°C for 3 minutes, take it out and spray 15wt% potassium bicarbonate solution, control the weight of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com