Method for theoretically predicting burning rate of water ramjet with high metal content

A technology of engine and water stamping, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

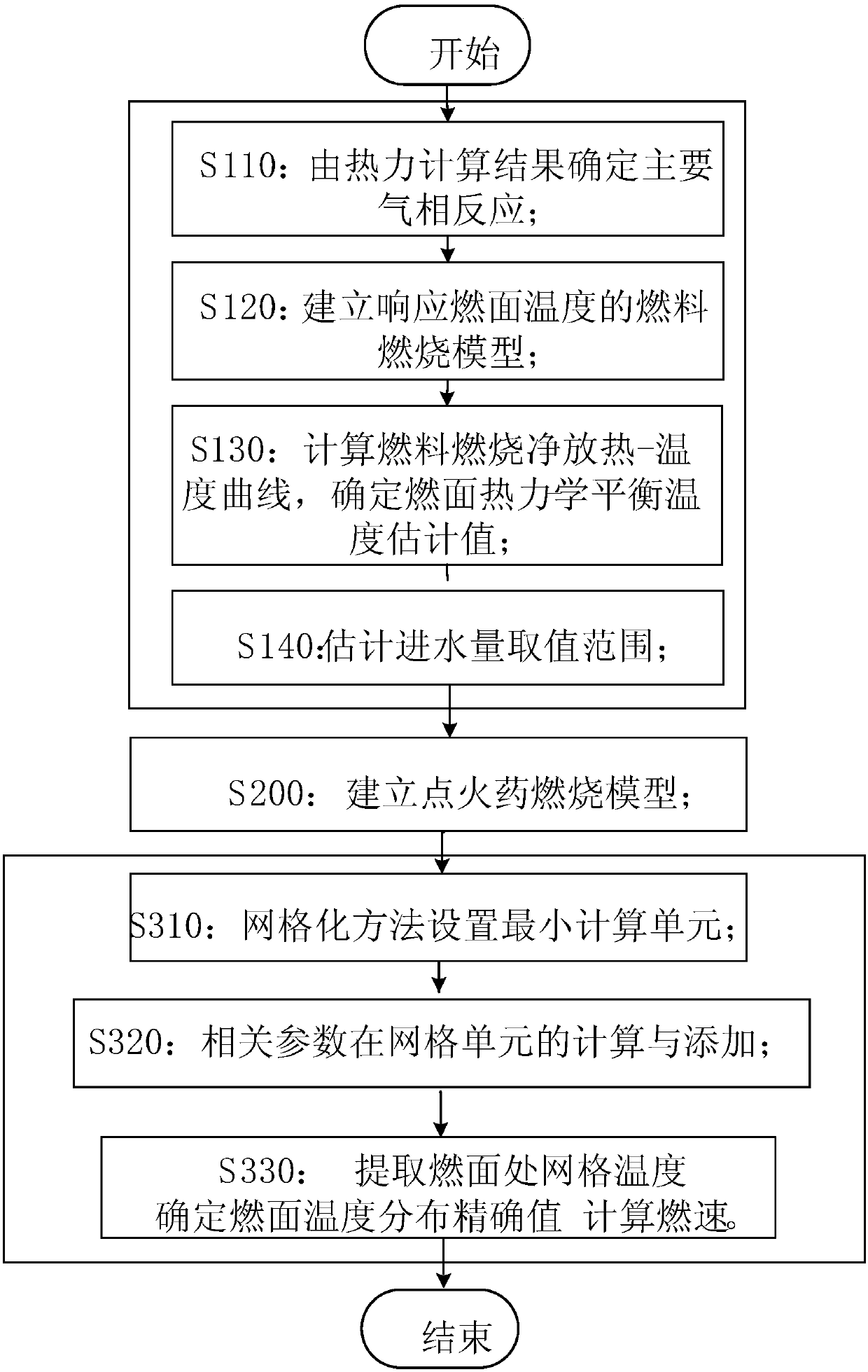

[0073] A theoretical prediction method for the combustion rate of high metal content water ramjet engines based on the equilibrium temperature of the combustion surface, such as figure 1 shown, including the following steps:

[0074] Step S100: establishing a fuel combustion model for the ignition process of the water-reactive metal fuel;

[0075] Step S110: Determine the combustion products of the water-reactive metal fuel at combustion equilibrium through thermodynamic calculations, the combustion products are products whose mass fraction accounts for more than 1% of the total mass of substances in the combustion system, and determine the combustion products in the combustion system according to the combustion products The main reaction in the gas phase reaction zone;

[0076] Step S120: Establish a fuel combustion model responsive to the burning surface temperature according to the main reaction, and the fuel combustion model responsive to the burning surface temperature i...

Embodiment 2

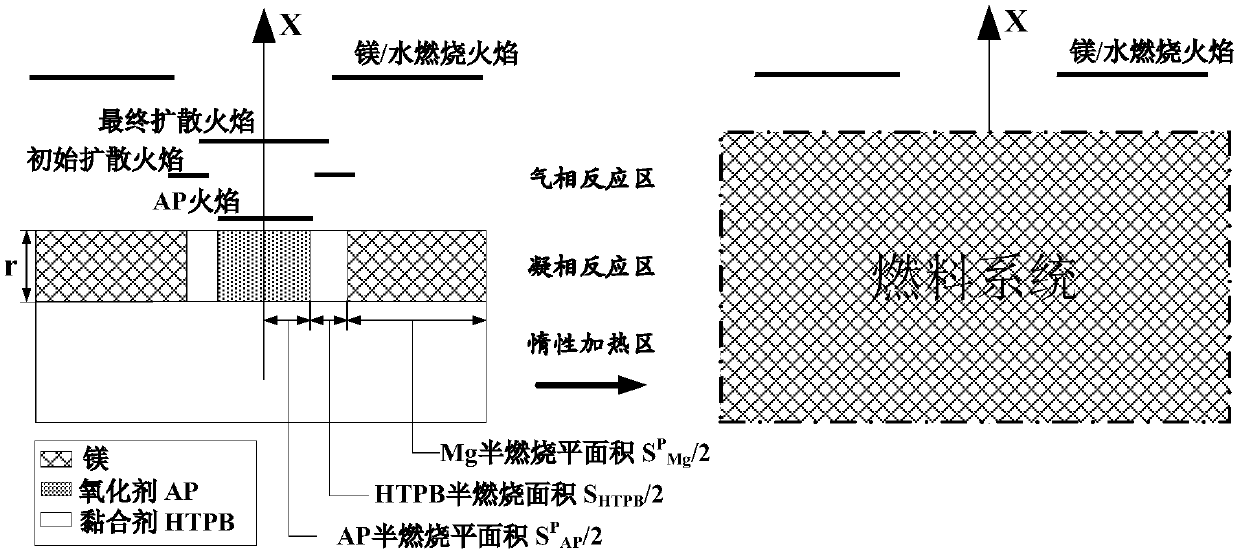

[0085] A theoretical method for predicting the burning rate of a water ramjet with a high metal content based on the combustion surface equilibrium temperature with a 73% magnesium-based water-reactive metal fuel (Mg73%wt / AP19%wt / HTPB8%wt) system as the water metal fuel comprises the following steps:

[0086] Step S100: Establish a combustion model for the ignition process of the water-reactive metal fuel.

[0087] Step S110 determines the combustion products at fuel balance through thermodynamic calculations. To simplify the calculation, only the parts with a mass percentage greater than 1% are considered. The component categories and their respective mass percentages are listed in Table 1.

[0088] Table 1 73% Mg-based water ramjet fuel combustion equilibrium product composition list

[0089]

[0090] According to AP(NH 4 ClO4 ), HTPB (C 4 h 6.052 o 0.052 ) and thermal decomposition characteristics of Mg and combustion products, assuming the main reaction in the gas p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com