Method for extracting, separating and identifying volatile bitter and astringent taste substances in Baijiu

A volatile and astringent technology, applied in the field of extraction, separation and identification of volatile bitter and astringent substances in liquor, can solve the problems of research reports on volatile taste substances, inability to reflect scientific nature, and heavy workload, and achieve improved separation. and identification efficiency, practicability, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Extraction and separation of volatile bitter and astringent compounds in sesame flavor liquor

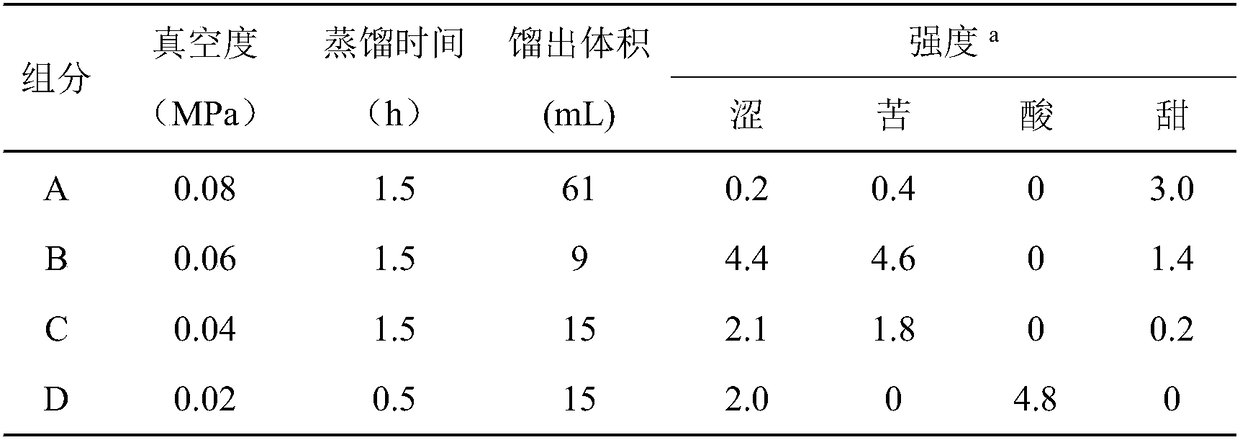

[0028](1) Gradient decompression distillation to extract bitter and astringent compounds in liquor: take 100mL wine sample and put it in a 250mL rotary evaporator, carry out gradient decompression distillation (0.08, 0.06, 0.04, 0.02MPa), set up different water bath heating Temperature (40, 50, 60, 70, 80, 85, 90°C), explore the minimum heating temperature at which the liquid can be distilled at the minimum vacuum (0.08MPa). The results show that when the temperature of the water bath is lower than 85°C, no liquid distills out of the receiving phase, and only when the temperature of the water bath reaches 85°C or higher, the liquid distills out of the receiving phase. Therefore, 85°C is selected as the heating condition of the water bath, and the gradient Distill under reduced pressure and collect the receiving phase. Distillation under each gradient vacuum condit...

Embodiment 2

[0034] Identification of Volatile Bitter and Astringent Compounds in Sesame Flavor Liquor in Example 2

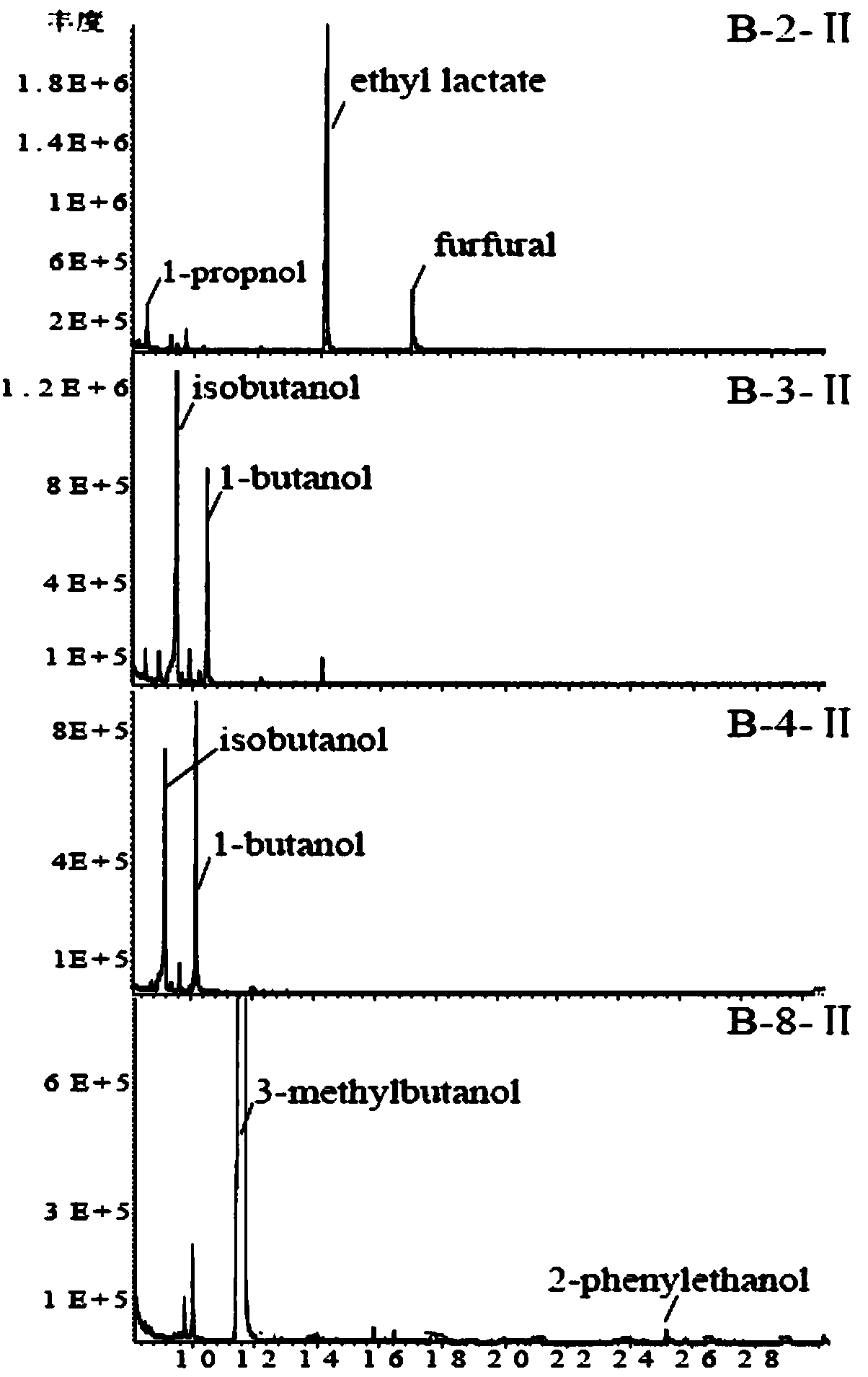

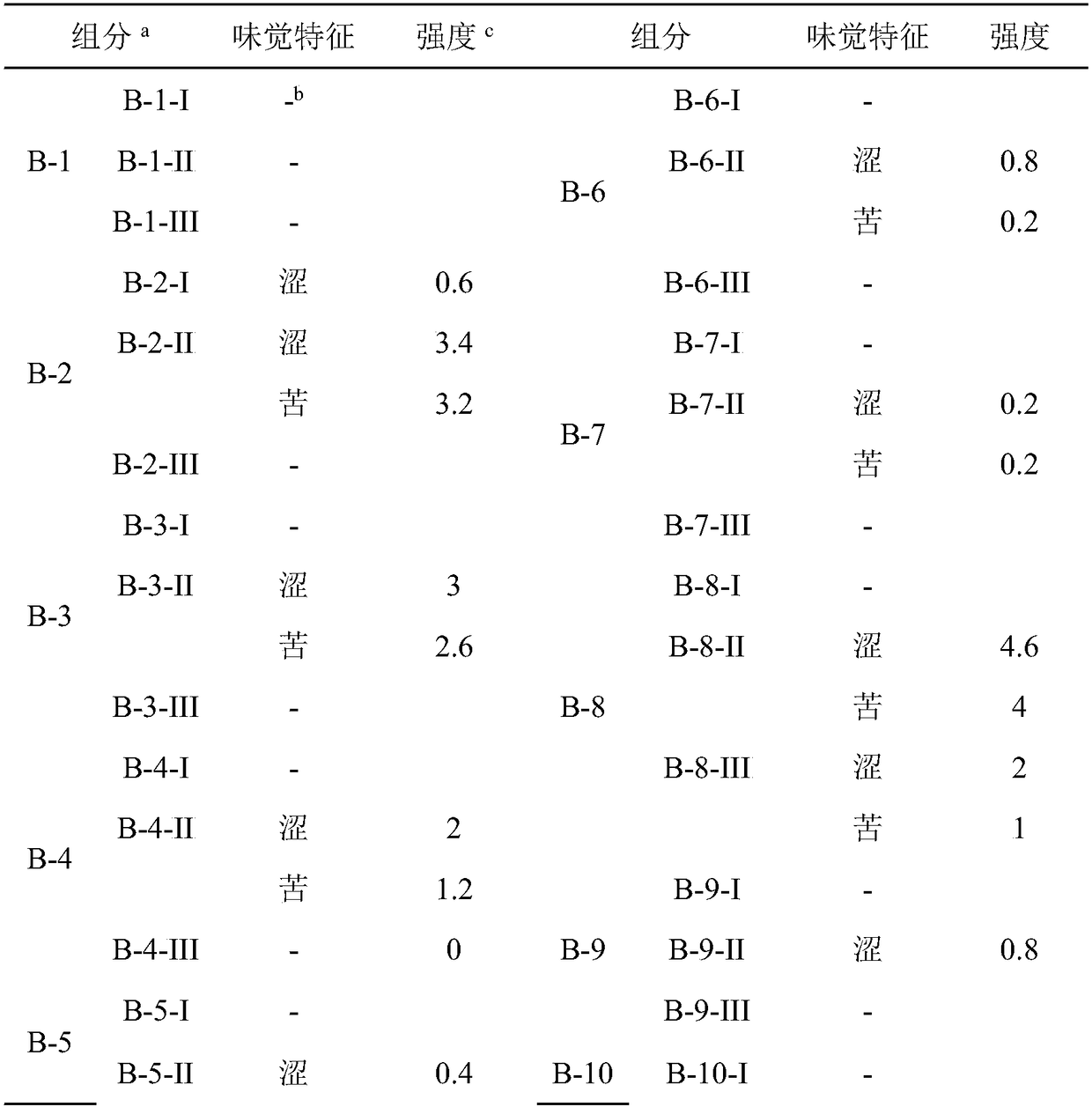

[0035] (1) Taste evaluation of the water-washed phase after solvent extraction in Example 1. The results of the taste evaluation are shown in Table 2. The taste compounds mainly exist in the ether extraction phase, i.e. in subcomponent II, and are both astringent It was bitter again. Among them, the intensity of bitterness and astringency of subcomponent B-8-II is the highest, which are 4.6 and 4 respectively; followed by subcomponent B-2-II, which are 3.4 and 3.2 respectively; thirdly, subcomponent B-3- II, with strengths of 3 and 2.6, respectively. The pentane extract phase (subfraction I) had little gustatory activity; B-4-III, B-6-III and B-8-III in the post-extraction residual phase (subfraction III) exhibited a slight gustatory character. Subcomponent II with higher taste intensity was selected for TDA.

[0036] Table 2 Taste characteristics and intensity of solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com