Feature extraction method for performance degradation evaluation of rolling bearing

A rolling bearing and feature extraction technology, applied in the field of rolling bearing performance testing, can solve problems such as difficult to adapt to performance degradation evaluation, and achieve the effect of improving representation ability and eliminating the influence of noise and interference components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

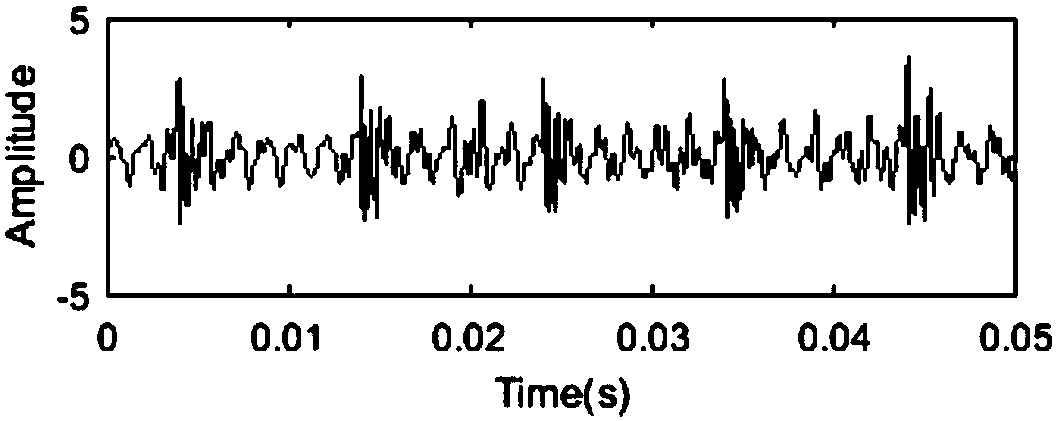

[0049] Embodiment 1 The original signal to be analyzed is composed of a periodic exponential decay pulse signal with a repetition period of 0.01s, a band-limited Gaussian white noise and a sinusoidal signal. image 3 is the time-domain waveform of the original signal to be analyzed, Figure 4 is the time-domain waveform of the three signal components contained in the original signal to be analyzed.

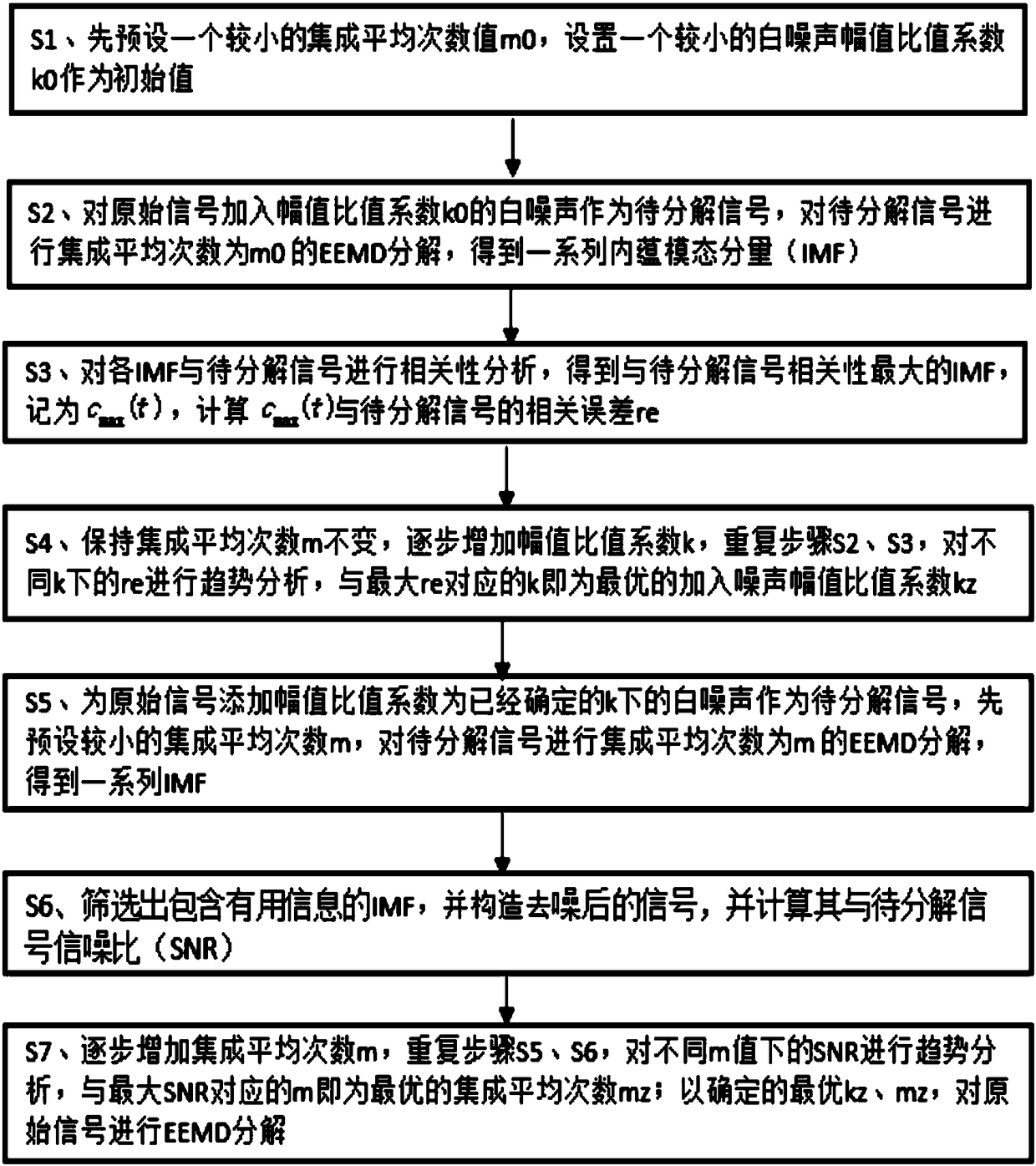

[0050] In order to more clearly illustrate the embodiment of the present invention or the technical solution in the prior art, the following will apply the first example of the embodiment as follows figure 2 An EEMD method for adaptive determination of decomposition parameters shown in the figure is analyzed, which specifically includes the following steps:

[0051] S1: Pre-set the integrated average value m 0 and white noise amplitude ratio coefficient k 0 As the initial value, in order to reduce the amount of signal decomposition calculation in the process of adaptively obta...

Embodiment 2

[0064] The raw data of Example 2 are provided by the Bearing Data Center of Western Reserve University. The test bearing is a 6205-2RSJEM SKF deep groove ball bearing. The collected vibration acceleration signals of rolling bearings include vibration signals in normal state and signals of different degrees of degradation of inner rings of different bearings (the diameters of the bearings are set to 0.1778mm, 0.3556 mm and 0.5334mm single point damage failure).

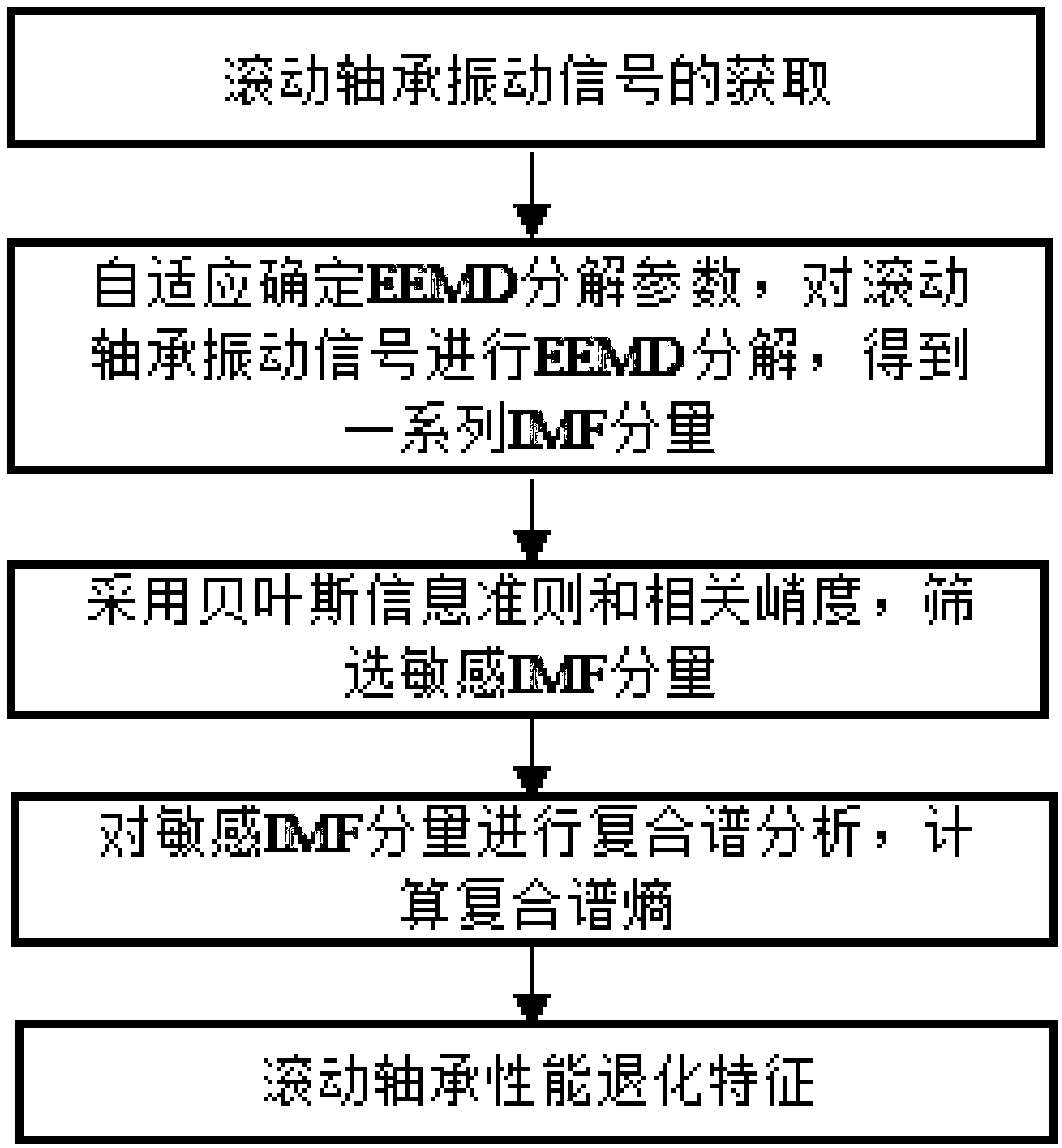

[0065] In order to more clearly illustrate the embodiment of the present invention or the technical solution in the prior art, the following will apply the following to the embodiment figure 1 A feature extraction method for the performance degradation evaluation of rolling bearings is analyzed, which specifically includes the following steps:

[0066] (1) Obtain the vibration signal of the rolling bearing

[0067] (2) Carry out EEMD decomposition for adaptively determining the decomposition parameters of the rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com