Steel forging resistant to compression and corrosion, and machining method thereof

A corrosion-resistant steel and processing method technology, applied in the field of steel processing, can solve the problems of low comprehensive effect, low balance of yield strength, tensile strength and corrosion resistance of stainless steel forgings, low comprehensive performance of forgings, etc., to achieve balance High, low temperature resistance, strong weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

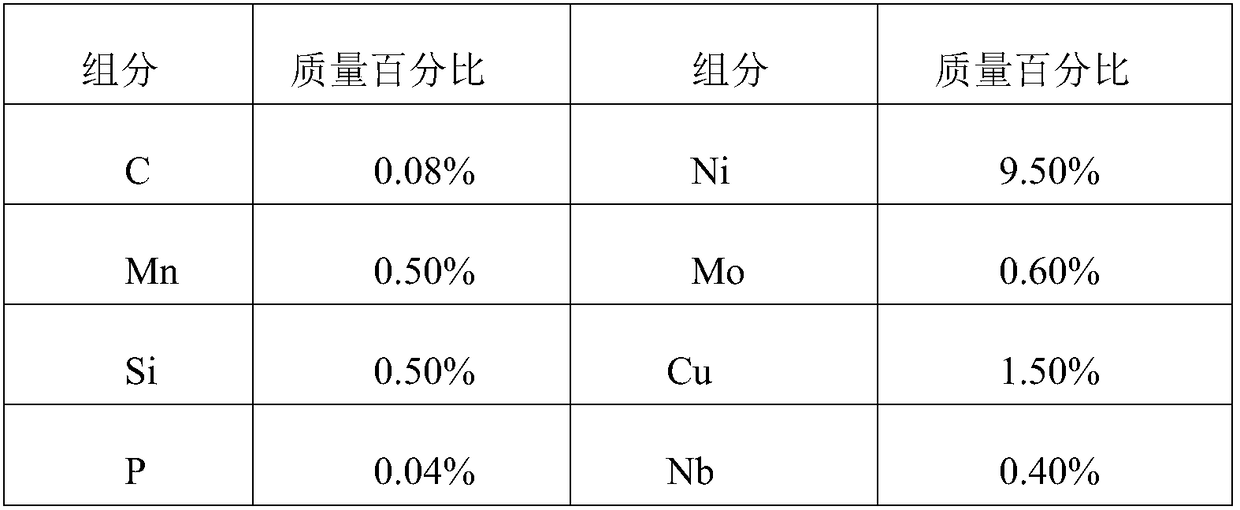

[0031] Table 1 Mass percentage of each element in a kind of compression and corrosion resistant steel forging of Example 1

[0032]

[0033]

Embodiment 2

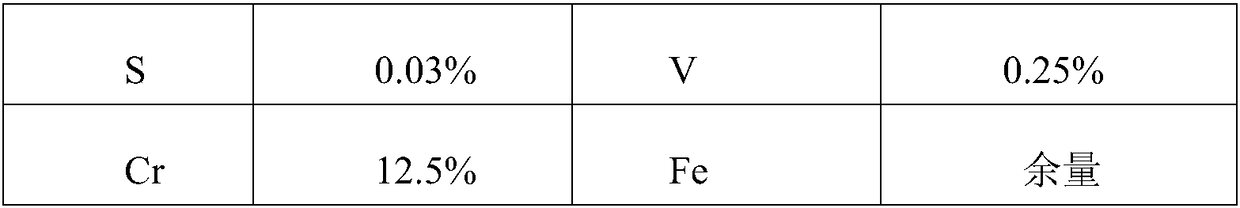

[0035] Table 2 Mass percentage of each element in a kind of compression and corrosion resistant steel forging of Example 2

[0036] components

Embodiment 3

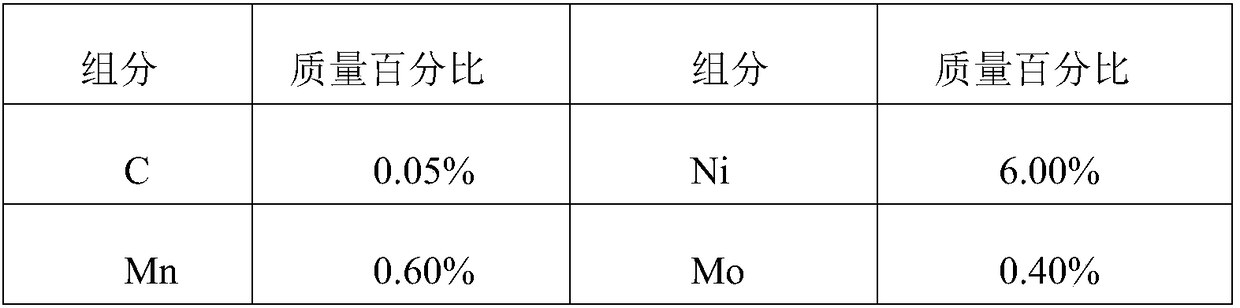

[0038] Table 3 Mass percentage of each element in a kind of compression and corrosion resistant steel forging of embodiment 3

[0039] components

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com