Tellurium beryllium copper alloy and preparation method thereof

A technology of beryllium copper alloy and master alloy, which is applied in the field of free-cutting tellurium beryllium copper alloy and its preparation, can solve the problems of reducing the plasticity of copper alloy, the mechanical properties of materials cannot be changed, corrosion and cracking, etc., and achieve the improvement of high temperature softening temperature and thermal processing Good stability and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of Tellurium Beryllium Copper Pipe by Extrusion Method

[0045] (1) According to the weight percentage of Table 1, the feeding order is copper cathode CATH-1, copper beryllium intermediate alloy (containing 4% beryllium), pure tellurium, copper-nickel intermediate alloy (containing 10% nickel), copper-cobalt intermediate alloy (10% cobalt), using 750Kg power frequency cored furnace non-vacuum induction electric furnace for smelting, the smelting temperature is 1170℃, after melting, the temperature is kept for 15 minutes, and argon gas is introduced to remove impurities and gas. After degassing and removing impurities, static Set for 15 minutes, then use a hydraulic semi-continuous casting machine to cast Φ155 round ingots, casting temperature 1100℃, argon protection, casting speed 150~250mm / min, cooling water pressure 0.3MPa, sawing cut to length Φ155×330;

[0046] (2) Hot extrusion of the round ingot at a temperature of 910℃, the extrusion ratio is 53:1, the ext...

Embodiment 2

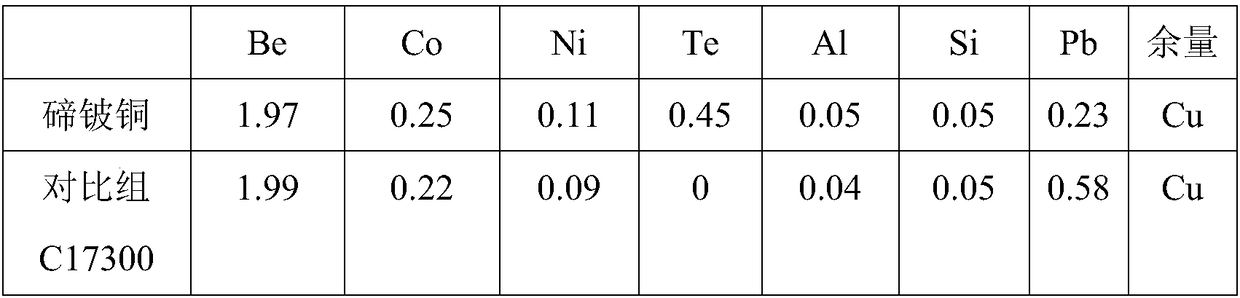

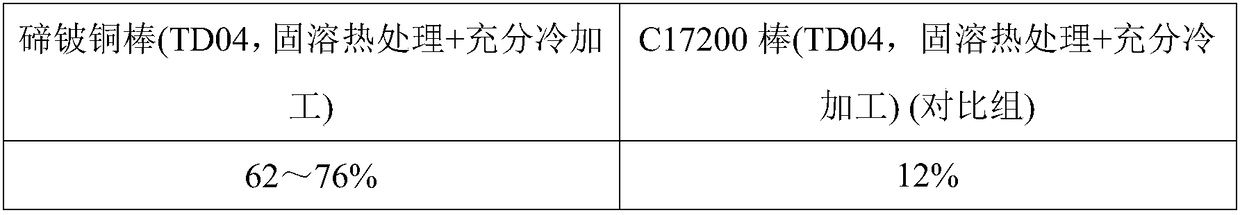

[0057] Preparation of Tellurium Beryllium Copper Bars by Continuous Casting

[0058] (1) According to the weight percentage in Table 4, the raw materials are cathode copper CATH-1, copper-beryllium intermediate alloy (containing 10% beryllium), copper-tellurium intermediate alloy (containing 10% tellurium), copper-nickel intermediate alloy (containing 10% nickel) ), copper-cobalt master alloy (10% cobalt), smelted in a vacuum induction electric furnace, first add cathode copper CATH-1, copper-tellurium master alloy (10% tellurium), copper-nickel master alloy (10% nickel), Copper-cobalt master alloy (containing 10% cobalt), after melting, use a vacuum feeding device to add copper-tellurium master alloy (containing 10% tellurium) and copper-beryllium master alloy (containing 10% beryllium). After melting, heat up to 1270℃, and remove slag at high temperature , Then cool down to 1120℃ with low power, keep for 20min, keep continuous vacuum during the above process, and keep the vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com