Preparation method of heat conducting glue with low viscosity and high thermal conductivity

A high thermal conductivity, thermally conductive adhesive technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of high thermally conductive adhesives, difficulty in laminating heavy work, etc., and achieve the effect of good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

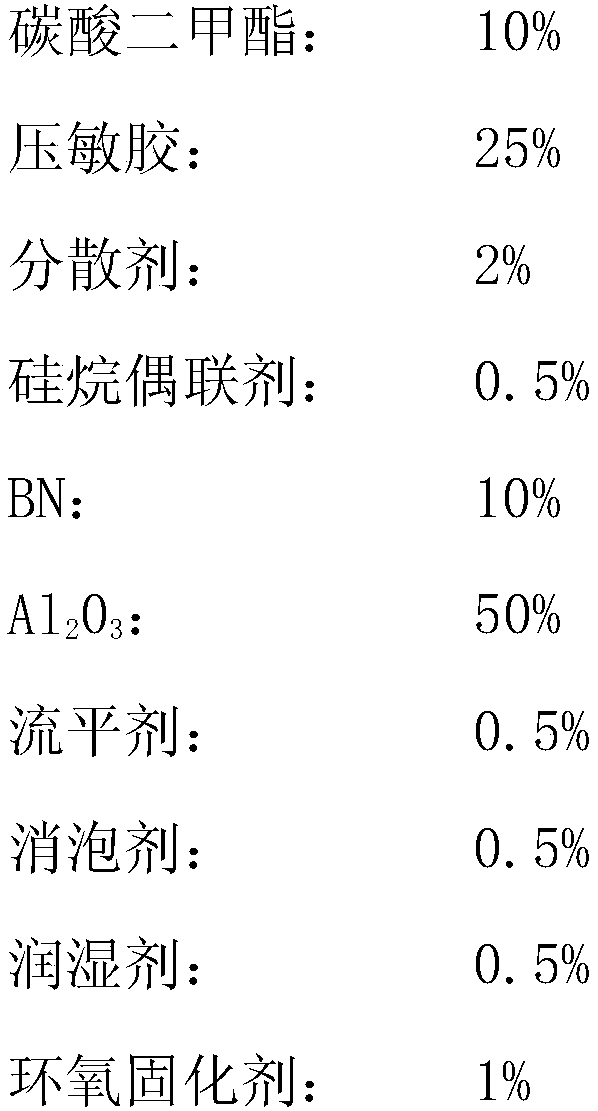

[0022] A method for preparing a thermally conductive adhesive with low viscosity and high thermal conductivity, the mass percentage of each component is:

[0023]

[0024] (1) According to the above formula, weigh the dispersant and silane coupling agent and dilute with dimethyl carbonate, add thermal conductive fillers BN and Al 2 0 3 , use a homogenizer at a speed of 1500rpm, mix for 2min;

[0025] (2) Add pressure-sensitive adhesive, and use a homogenizer to mix for 2 minutes at a speed of 1500 rpm;

[0026] (3) Add leveling agent, defoamer and wetting agent, and mix for 1 min at a speed of 1500 rpm using a homogenizer;

[0027] (4) Add epoxy curing agent, and use a homogenizer to mix for 1 min at a speed of 1500 rpm;

[0028] (5) Coating the mixture on both sides of the substrate, curing and drying at 80-90° C. for 10-20 minutes, to obtain a thermally conductive adhesive with low viscosity and high thermal conductivity.

Embodiment 2

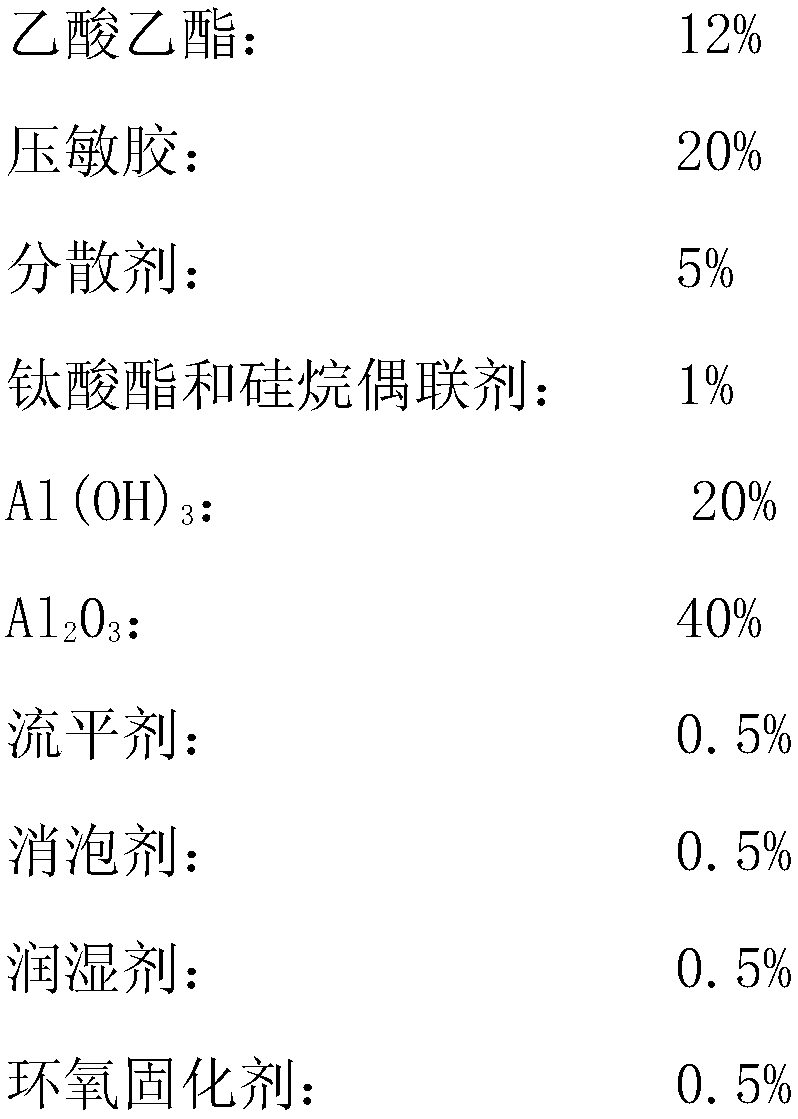

[0030] A method for preparing a thermally conductive adhesive with low viscosity and high thermal conductivity, the mass percentage of each component is:

[0031]

[0032] (1) According to the above formula, weigh the dispersant, titanate and silane coupling agent and dilute with ethyl acetate, add the thermal conductive filler Al(OH) 3 and Al 2 0 3 , use a homogenizer at a speed of 1500rpm, mix for 2min;

[0033] (2) Add pressure-sensitive adhesive, and use a homogenizer to mix for 2 minutes at a speed of 1500 rpm;

[0034] (3) Add leveling agent, defoamer and wetting agent, and mix for 1 min at a speed of 1500 rpm using a homogenizer;

[0035] (4) Add epoxy curing agent, and use a homogenizer to mix for 1 min at a speed of 1500 rpm;

[0036] (5) Coating the mixture on both sides of the substrate, curing and drying at 80-90° C. for 10-20 minutes, to obtain a thermally conductive adhesive with low viscosity and high thermal conductivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com