Method for extracting low-molecular-weight lignin from biomass

A low molecular weight, lignin technology, applied in the field of biomass component separation, can solve the problems of high price of organic solvents, loss of active functional groups, poor biodegradability, etc., and achieve the effect of low price, mild reaction and easy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

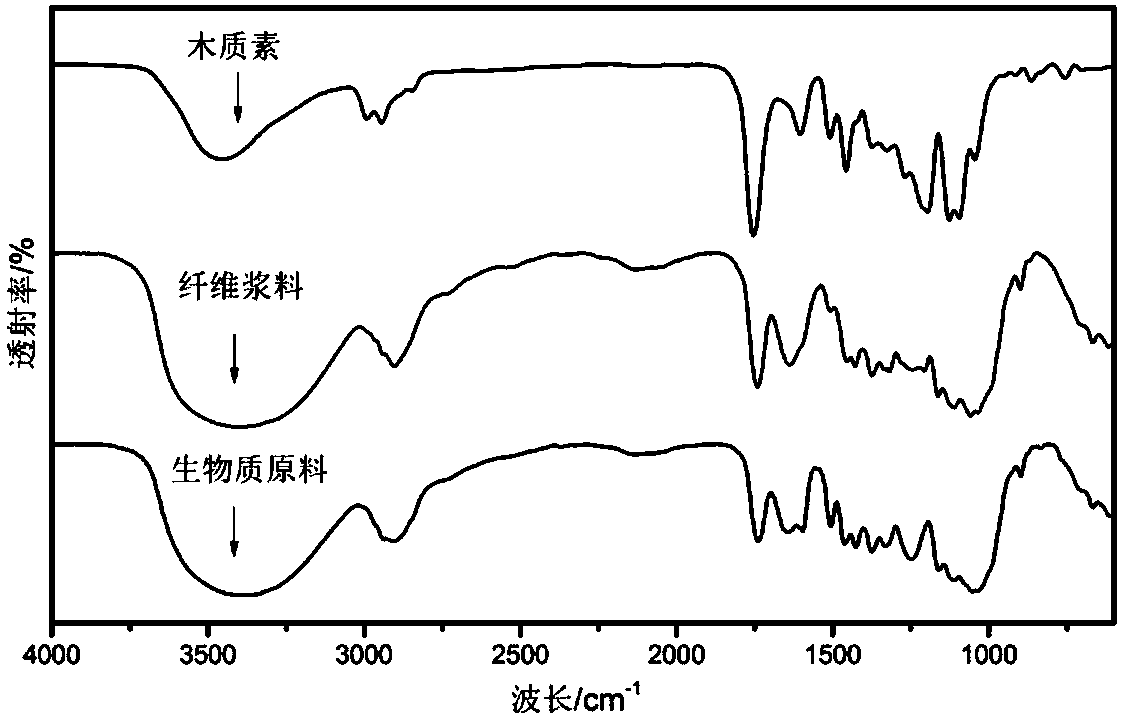

Image

Examples

Embodiment 1

[0033] A method for extracting low molecular weight lignin from biomass, comprising the steps of:

[0034] (1) Preparation of extractant: choline chloride and lactic acid were prepared as a mixed solution at a molar mass ratio of 1:10, and then reacted at 40°C for 1 hour to form a homogeneous solution to obtain the extractant.

[0035] (2) Preparation of biomass raw material: after crushing and screening air-dried bamboo willow, take 40-mesh powder and store it under vacuum drying condition at 70°C for 24 hours to obtain bamboo willow biomass raw material.

[0036] (3) Extraction: the extractant in step (1) is added to the biomass raw material in step (2), adding H 5 PMo 10 V 2 o 40 , the weight ratio of the three is 28:1:0.15, and then react at 100°C for 18h while stirring, filter with a G2 filter, precipitate with a large amount of deionized water and centrifuge to obtain a solid substance, and then use 1:10 absolute ethanol / The solid matter is washed with deionized wat...

Embodiment 2

[0041] A method for extracting low molecular weight lignin from biomass, comprising the steps of:

[0042] (1) Preparation of extractant: choline chloride and lactic acid were prepared into a mixed solution with a molar mass ratio of 1:8, and then reacted at 60°C for 1 hour to form a homogeneous solution to obtain the extractant.

[0043] (2) Preparation of biomass raw material: after crushing and screening air-dried bamboo willow, take 60-mesh powder and store it under vacuum drying condition at 70° C. for 22 hours to obtain bamboo willow biomass raw material.

[0044] (3) Extraction: the extractant in step (1) is added to the biomass raw material in step (2), adding H 5 PMo 10 V 2 o 40 , the weight ratio of the three is 30:1:0.1, and then react at 90°C for 12h while stirring, filter with a G2 filter, precipitate with deionized water and centrifuge to obtain a solid substance, and then use 1:10 absolute ethanol / deionized The solid matter is washed with ion water and dried...

Embodiment 3

[0047] A method for extracting low molecular weight lignin from biomass, comprising the steps of:

[0048] (1) Preparation of extractant: choline chloride and lactic acid were prepared into a mixed solution at a molar mass ratio of 1:6, and then reacted at 80°C for 2 hours to form a homogeneous solution to obtain the extractant.

[0049] (2) Preparation of biomass raw material: After the air-dried bamboo willow was crushed and screened, 80-mesh powder was taken and stored under vacuum drying at 60°C for 22 hours to obtain the bamboo willow biomass raw material.

[0050] (3) Extraction: the extractant in step (1) is added to the biomass raw material in step (2), adding H 5 PMo 10 V 2 o 40 , the weight ratio of the three is 40:1:0.05, and then react at 80°C for 9h while stirring, filter with a G2 filter, add deionized water to precipitate and centrifuge to obtain a solid substance, and then use 1:9 absolute ethanol / deionized The solid matter is washed with ion water and drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com