Preparation method of 3D printing precoated sand and made 3D printing precoated sand

A technology of 3D printing and coated sand, applied in the field of coated sand, can solve the problem that the strength of coated sand is difficult to meet, and achieve the effects of increasing strength, efficient use of atoms, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

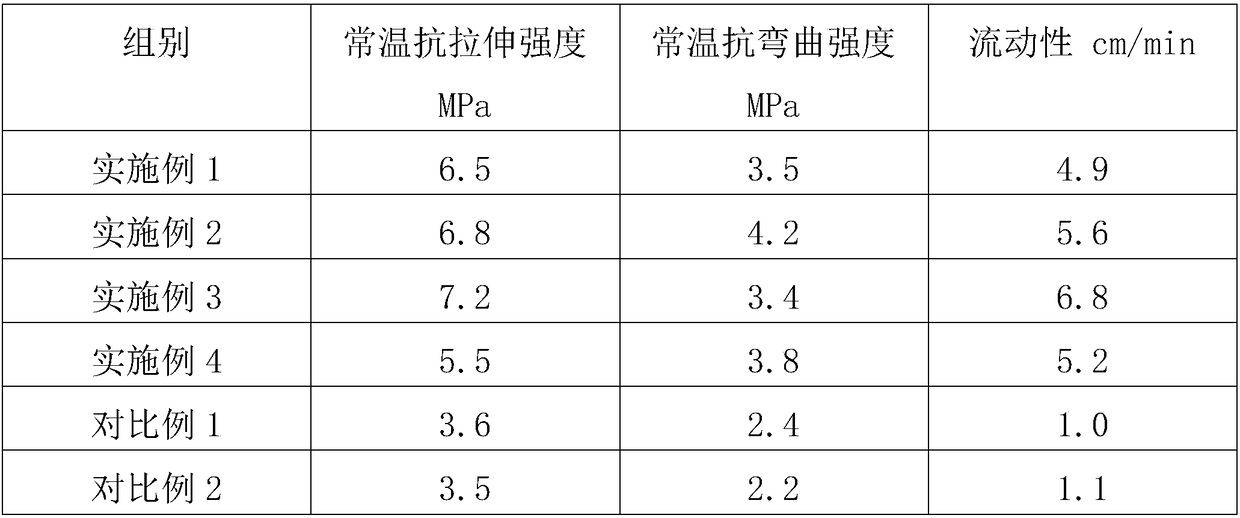

Examples

Embodiment 1

[0026] A preparation method of 3D printing coated sand is characterized in that it comprises the following steps:

[0027] (1) Preparation of raw sand: After mixing quartz sand, silica sand, and chromite sand in a mass ratio of 8:6:4, soak them in an acid solution with a mass fraction of 70% at 180°C for 24 hours, and filter out the sand particles. Calcined in a high-temperature furnace at 1000°C for 8 hours, then cooled to room temperature, and sieved to obtain raw sand;

[0028] (2) Raw sand modification: add raw sand, titanate coupling agent, and dibutyltin diacetate into the mixer at a mass ratio of 100:3:0.3, and stir for 30 minutes at a temperature of 150°C and a stirring speed of 600rpm Take it out to obtain the first mixture, then add 120 parts of the first mixture, 15 parts of the first binder and 2 parts of stearic alcohol into the mixer, stir at 250 °C and 800 rpm for 60 minutes, and then add 5 parts of the first binder and 10 parts of the second binder were stirre...

Embodiment 2

[0033] A preparation method of 3D printing coated sand is characterized in that it comprises the following steps:

[0034] (1) Preparation of raw sand: After mixing quartz sand, silica sand, and chromite sand in a mass ratio of 6:6:3, soak them in an acid solution with a mass fraction of 80% at 180°C for 20 hours, and filter out the sand particles. Calcined in a high-temperature furnace at 1200°C for 6 hours, then cooled to room temperature, and sieved to obtain raw sand;

[0035](2) Raw sand modification: Add raw sand, silane coupling agent, and stannous octoate into the mixer at a mass ratio of 120:5:0.2, stir at 140°C and 800rpm for 20 minutes, and then take it out to obtain For the first mixture, add 100 parts of the first mixture, 12 parts of the first binder and 2 parts of stearic acid amide into the mixer, stir for 75 minutes at a temperature of 240 ° C and a stirring speed of 600 rpm, and then add 3 parts of the first mixture One binder and 8 parts of the second binde...

Embodiment 3

[0040] A preparation method of 3D printing coated sand is characterized in that it comprises the following steps:

[0041] (1) Preparation of raw sand: After mixing quartz sand, silica sand, and chromite sand in a mass ratio of 8:5:4, soak them in an acid solution with a mass fraction of 90% at 200°C for 25 hours, and filter out the sand particles. Calcined in a high-temperature furnace at 1200°C for 5 hours, then cooled to room temperature, and sieved to obtain raw sand;

[0042] (2) Raw sand modification: Add raw sand, titanate coupling agent, and dibutyltin di(dodecylsulfide) into the mixer at a mass ratio of 100:3:0.2, and heat the mixture at 150°C and 700rpm Stir at the stirring speed for 30 minutes and then take it out to obtain the first mixture, then add 120 parts of the first mixture, 15 parts of the first binder and 1 part of ricinoleic acid phthalimide into the mixer, at a temperature of 250°C and a stirring speed of 700rpm After stirring at low temperature for 70 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com