Novel wire and application thereof

A wire, a new technology, applied in the new wire and its application field, can solve the problems of limited elongation and deformation of ceramic fibers, reduce tower distance, large thermal sag, etc., achieve the effect of superior weight ratio, reduce wind resistance and ice load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

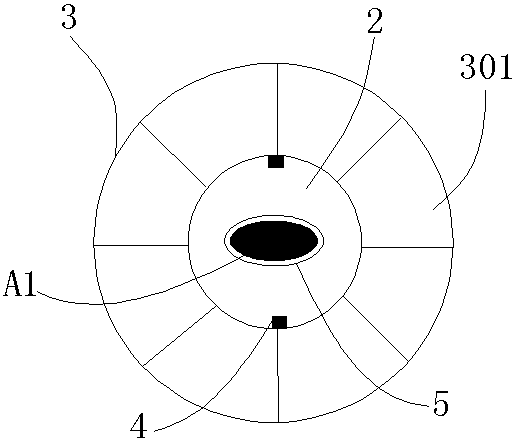

[0079] Such as figure 1 As shown, a new type of wire is sequentially composed of a load-bearing core, a conductor coating layer 2, and a conductor stranding layer 3 from inside to outside; the surface layer of the load-bearing core is provided with an anti-corrosion insulating layer 5.

[0080] The load-bearing core is a special-shaped load-bearing core A1; the effective diameter of the load-bearing core A1 is 1-25 mm; the cross-section of the special-shaped load-bearing core is square, rectangular, oval, flat or polygonal.

[0081] The thickness of the conductor coating layer 2 is ≥0.2mm, and the filling factor of the conductor coating layer is ≥94%; the conductor coating layer is aluminum, aluminum alloy, copper or copper alloy coating layer, and the conductor coating layer is one layer or Multi-layer; position calibration 4 is provided on the conductor cladding layer. The position calibration is to calibrate the orientation of the load-bearing core in the conductor claddin...

Embodiment 2

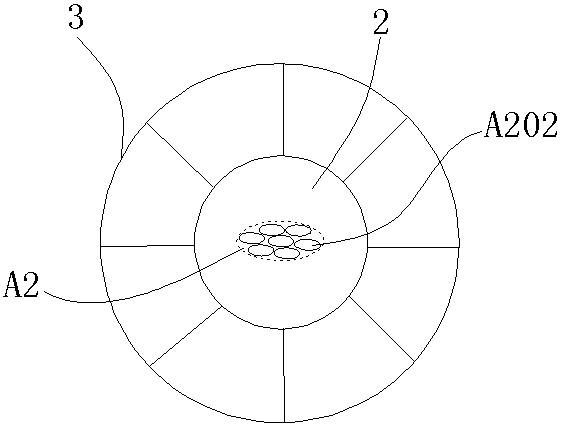

[0090] Such as figure 2 As shown, a new type of wire is sequentially composed of a load-bearing core, a conductor coating layer 2, and a conductor stranding layer 3 from inside to outside; the surface layer of the load-bearing core is provided with an anti-corrosion insulating layer 5.

[0091] The load-bearing core is a special-shaped load-bearing core group A2; the special-shaped load-bearing core group is composed of a plurality of special-shaped load-bearing cores arranged in a straight line or twisted, and the cross-section of the special-shaped load-bearing core group is non-circular.

[0092] The special-shaped force-bearing core group is composed of a plurality of special-shaped force-bearing mandrels A201; the diameter of the mandrels is 0.5-6mm.

[0093] In this embodiment, the diameter of the mandrel is 1-2 mm; the plurality of special-shaped load-bearing mandrels are arranged parallel to the wire axis to form a flat structure.

[0094] The thickness of the conduc...

Embodiment 3

[0104] Such as image 3 As shown, a new type of wire, from the inside to the outside is a different load-bearing core, a conductor cladding layer 2, and a conductor stranding layer 3; the load-bearing core is a carbon fiber flat wire A202 or a plurality of carbon fiber flat wires A202 Composition in a straight line.

[0105] In this implementation, the load-bearing core is composed of a plurality of flat carbon fiber wires A202 arranged in a straight line.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com