Refining-dyeing one-bath process efficient short-process dyeing and finishing process for chinlon knitted fabric

A short-process technology for knitted fabrics, which is applied in the field of one-bath high-efficiency short-process dyeing and finishing of nylon knitted fabrics, can solve the problems of time-consuming, long processing process, energy consumption, etc. The effect of fabric wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of functional finishing agent grafted with quaternary ammonium salt on the surface of nano-titanium dioxide:

[0035] Add 150mL acetone, 16 parts of nano-titanium dioxide, 3 parts of N,N-dimethyl-acryloyloxyethyl-propyltrimethoxysilane ammonium chloride into the stirrer, stir and react at 40°C for 24 hours, and centrifuge the mixture , washed twice with methanol, dried at 70°C to obtain surface-modified nano-titanium dioxide, and set aside;

[0036] Add 172 parts of water and 12 parts of surface-modified nano-titanium dioxide into the polymerization reactor, stir, raise the temperature of the water bath to 72 ° C, and drop 28 parts of N,N-dimethyl-acryloyloxyethyl-propyltrimethoxy The initiator solution of silane ammonium chloride, 0.6 parts of potassium persulfate and 14 parts of water is added dropwise after 2 hours, the temperature is raised to 80°C, the temperature is kept for 1 hour, and the temperature is lowered to below 50°C to obtain the nano-titani...

Embodiment 2

[0043] One-bath high-efficiency and short-process dyeing and finishing process for nylon knitted fabrics, including the following steps:

[0044] (1), Pre-type

[0045] 180~190℃, time 30s, speed 40~45m / min;

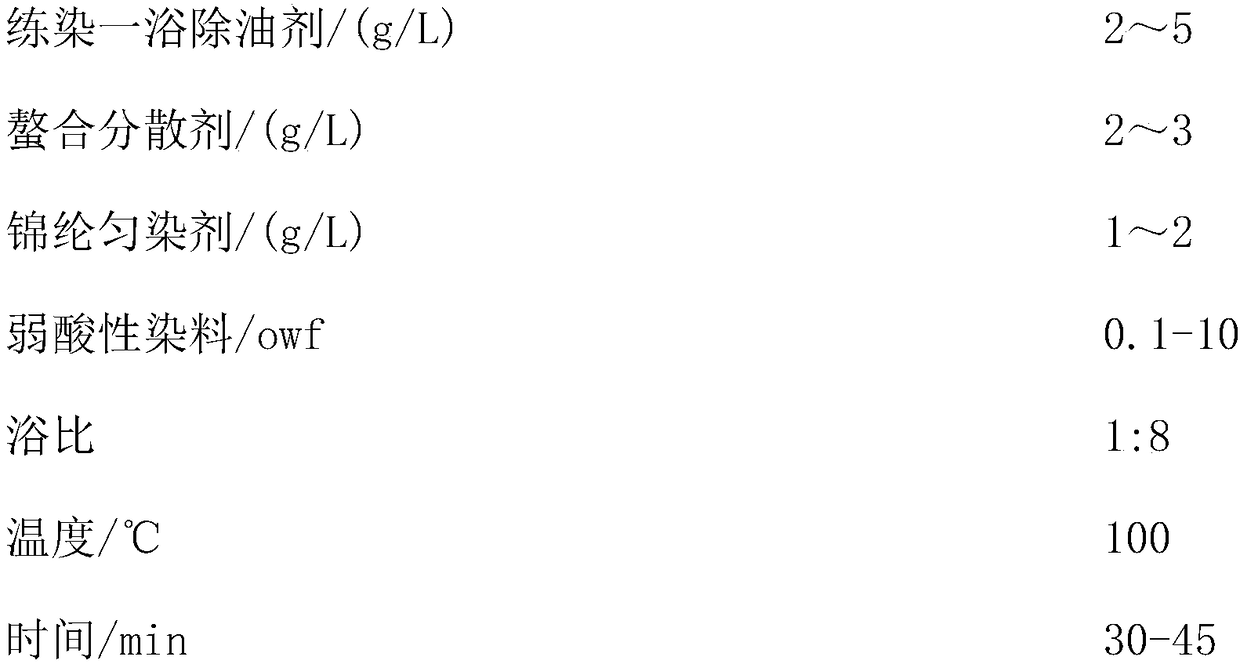

[0046] (2), refining, dyeing

[0047] The one-step process prescription for scouring and dyeing nylon knitted fabrics is as follows:

[0048]

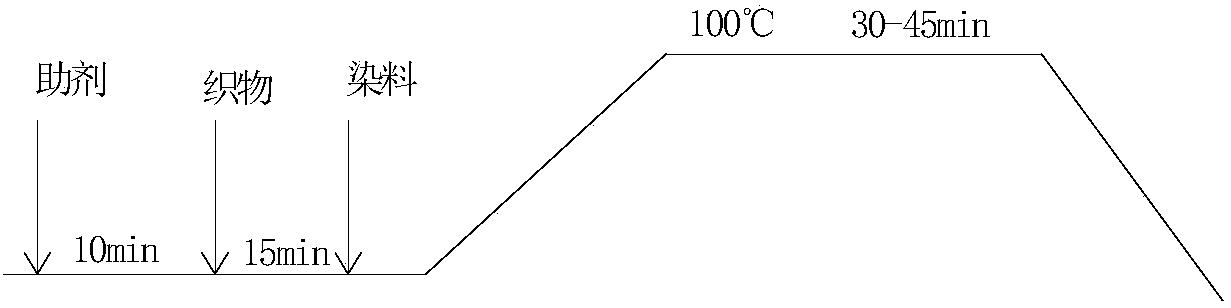

[0049] In the dyeing bath, add one-bath degreaser for training and dyeing (one-bath degreaser for training and dyeing (DR-838 Wuxi Derong Chemical Co., Ltd.), chelating dispersant (polyacrylic acid), nylon leveling agent (nylon leveling agent TF- 217B Zhejiang Chuanhua Co., Ltd. Fine Chemical Co., Ltd.), run for 10 minutes, then add nylon knitted fabric and run for 15 minutes, then add dye, adjust the pH value to 5-6, heat up to 100°C and dye for 30-45 minutes.

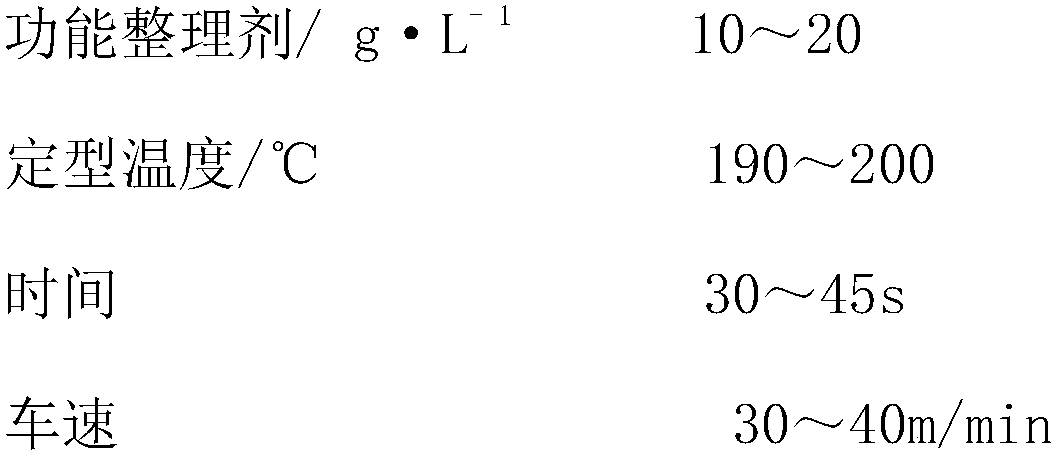

[0050] (3), finishing

[0051]

[0052] Wherein, the preparation method of functional finishing agent is:

[0053] Add 150mL acetone, 16 parts of nano-titanium d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com